Failure mode effects and criticality analysis method adopting two RPNs

A technology of failure modes and analysis methods, applied in electrical digital data processing, special data processing applications, instruments, etc., to solve problems such as hazards and failure mode effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

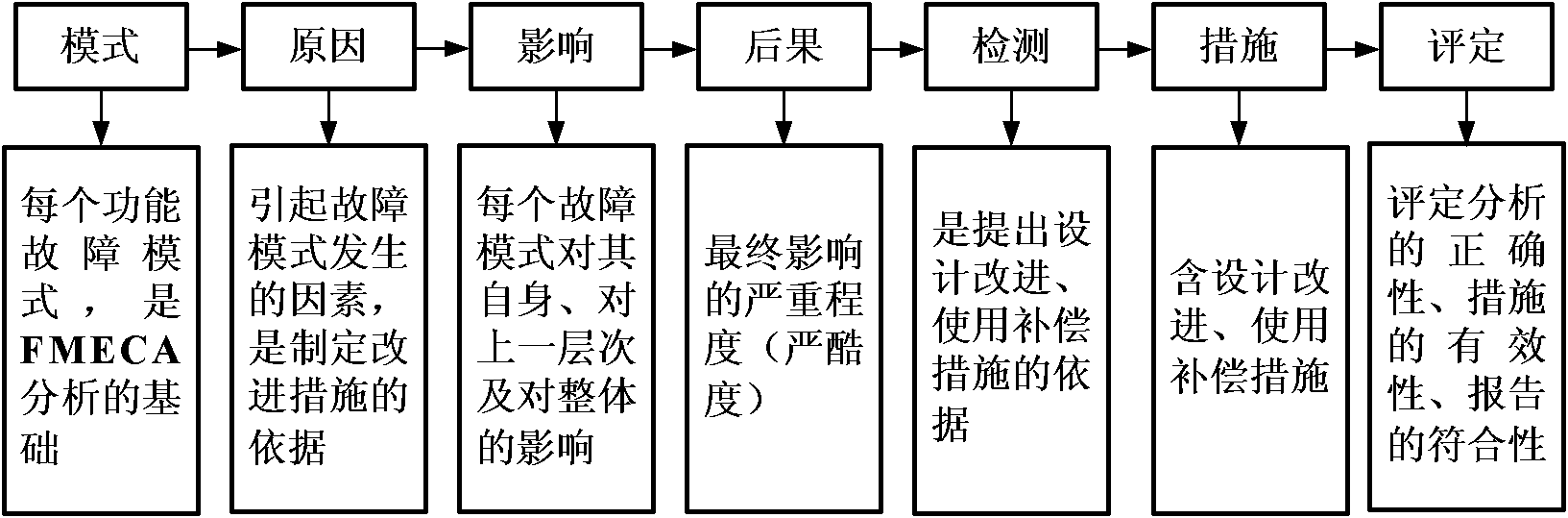

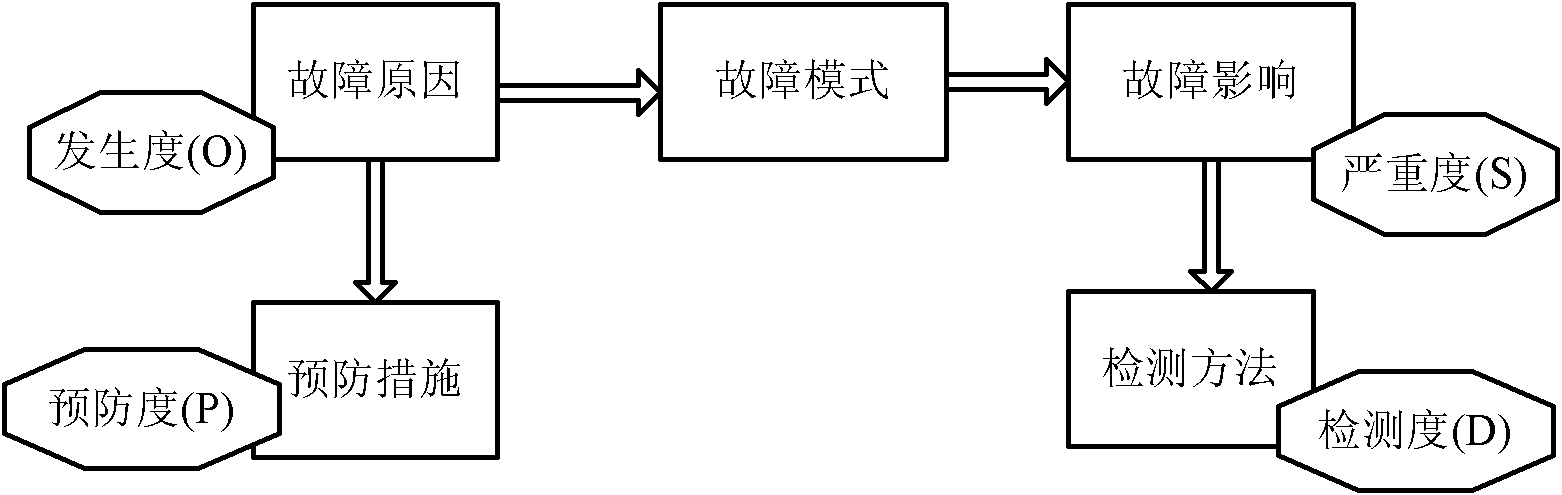

[0031] The FMECA model proposed in this paper adds the preventive degree index into the calculation of RPN number, which means "the effectiveness of the current design improvement scheme for preventing the occurrence of this fault". Distinguishing the preventive measures of failure from the detection measures will help designers focus on the improvement and optimization of the UAV product design process. The basic idea of the present invention is as figure 2 shown. From figure 2 It can be seen from the figure that the relationship between the analysis items of FMECA is as follows:

[0032] (1) There is a causal relationship between the failure cause and the failure mode, and a causal relationship between the failure mode and the failure effect;

[0033] (2) Taking the failure mode as the center, determine the failure effect and failure cause through analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com