Oil and gas compound burner

A burner, oil and gas technology, applied in the energy field, can solve the problems of high service conditions and complex structure, and achieve the effects of balanced combustion flame, convenient extraction and maintenance, and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

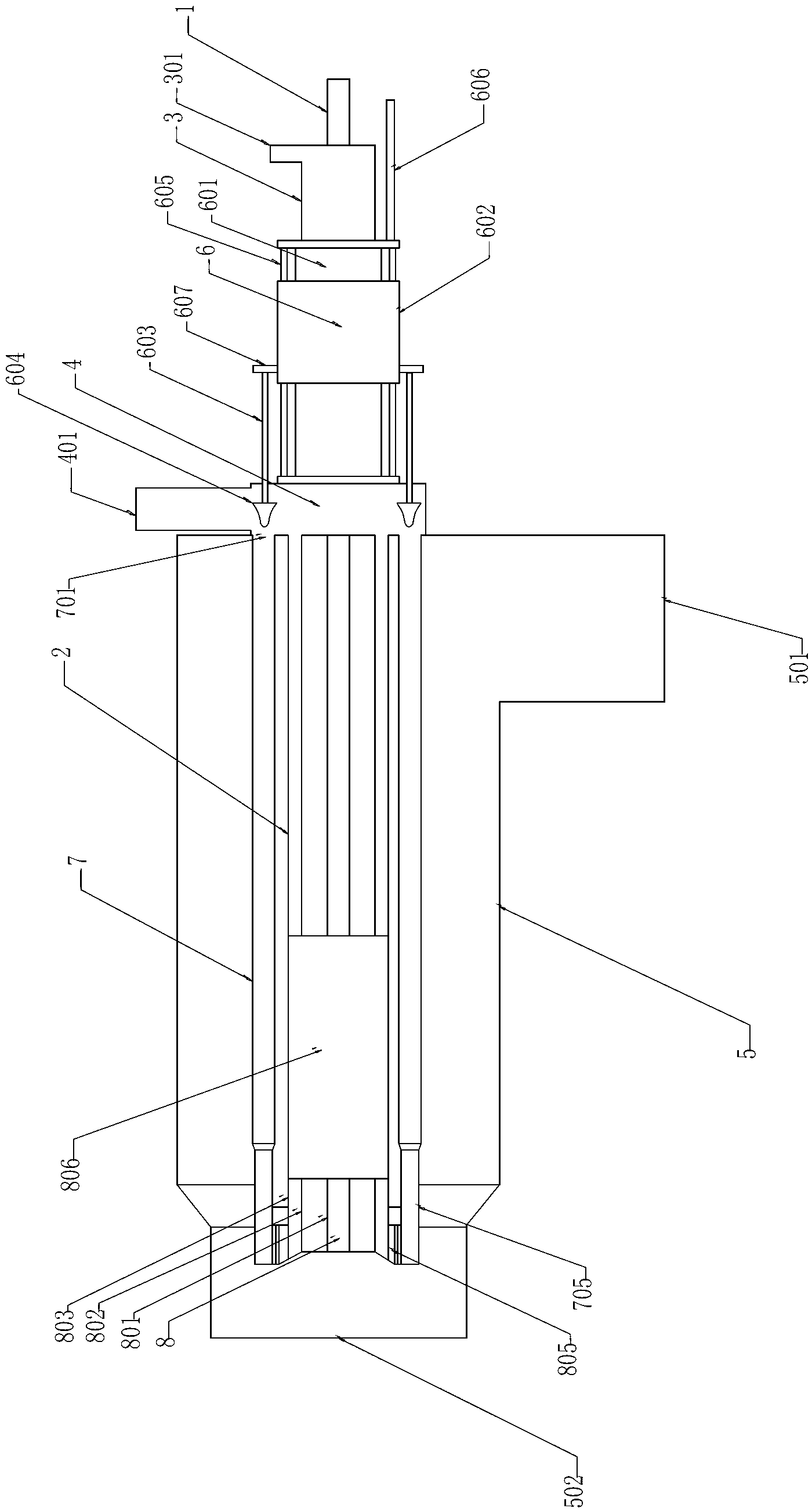

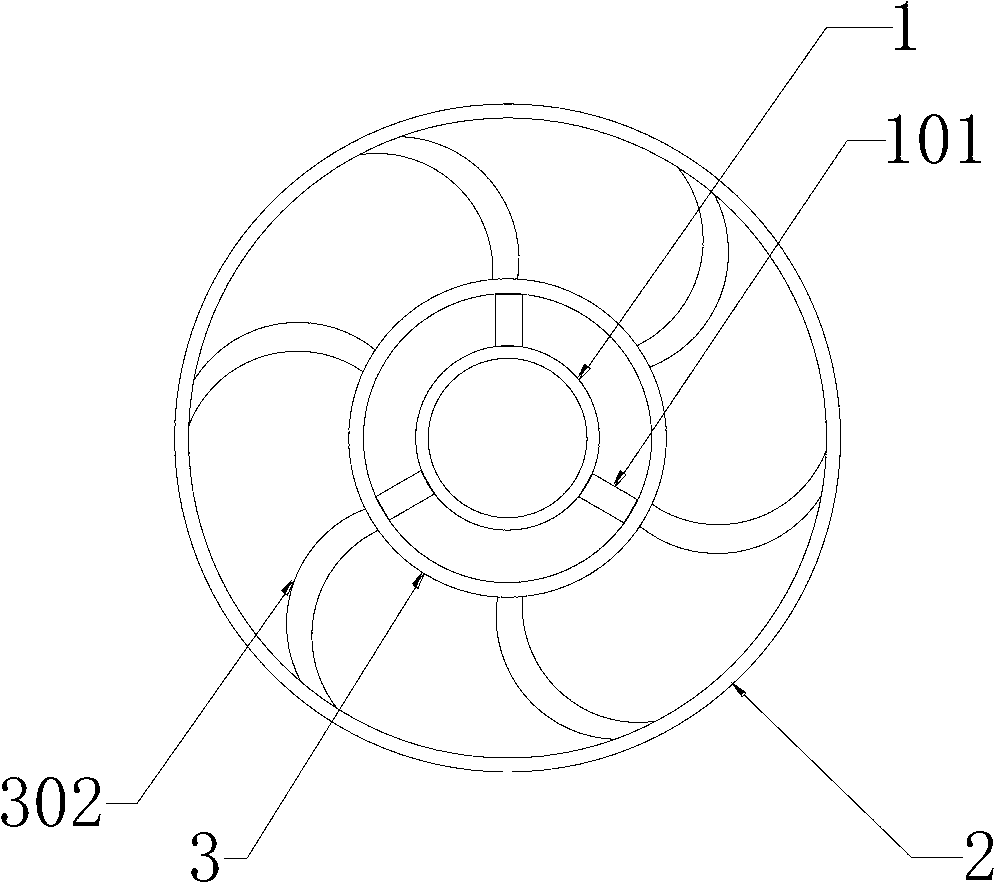

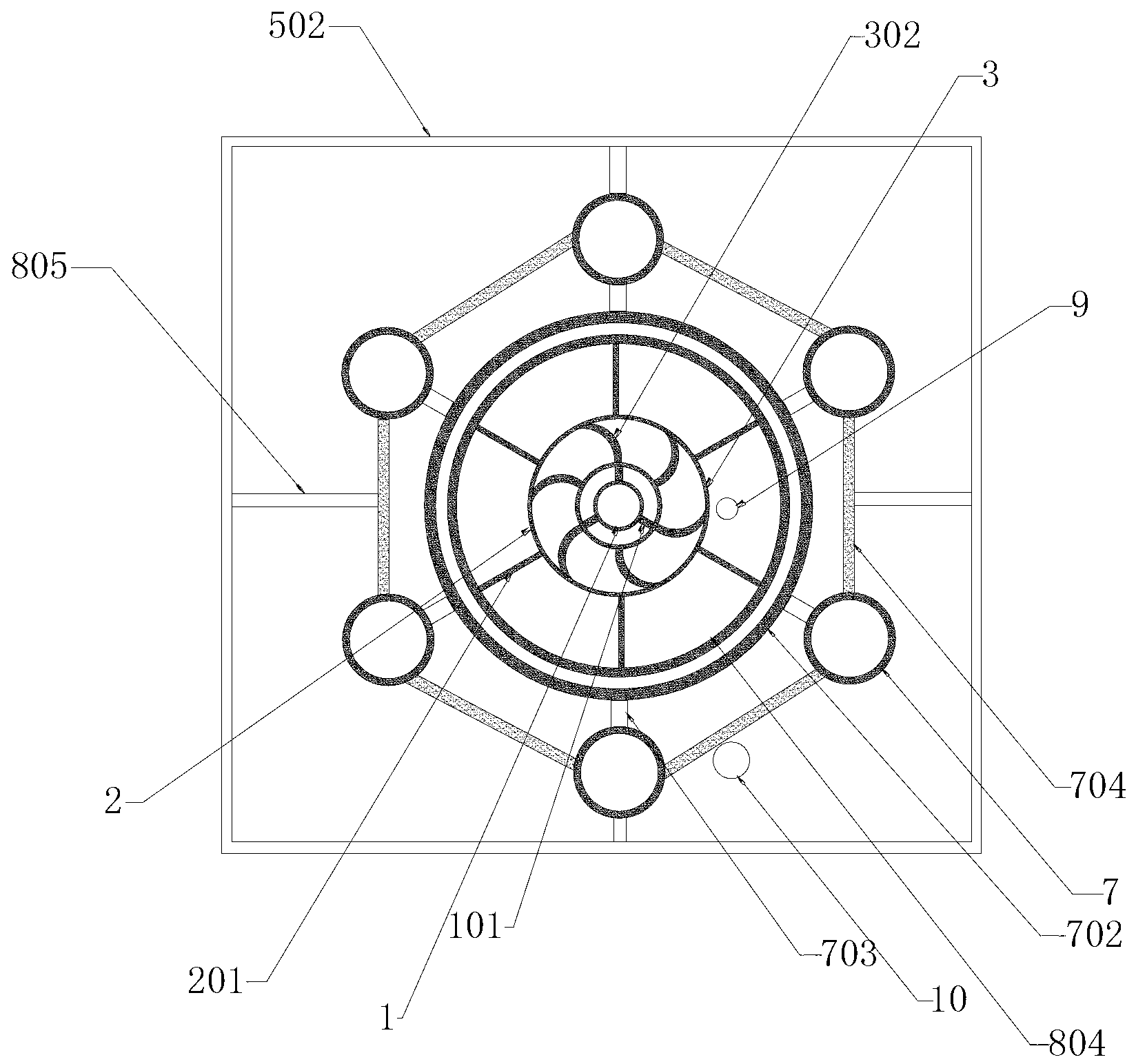

[0022] As shown in Figures 1 and 2, the oil-gas combustor of the present invention includes an oil pipe 1 for supplying oil, and a gas pipe 2 for supplying fuel gas sleeved outside the oil pipe 1. A combustion-supporting oil pipe 1 is provided between the gas pipe 2 and the oil pipe 1. The air casing 3, the oil pipe 1 is movably installed in the casing 3 through the oil pipe support rib 101 fixedly arranged on the outer surface, and the casing 3 is in sliding contact with the inner surface of the air pipe 2 through the inclined rotary vane 302 fixedly arranged on the outer surface A gas box 4 communicating with gas is provided at the air inlet end of the air pipe, and a wind box 5 containing the air pipe to provide combustion air is provided outside the air pipe 2, and an air inlet for air to enter is opened on the wind box 5 501 and the flame nozzle 502 corresponding to the gas outlet end of the gas pipe, an ignition device 9 and a flame monitor 10 for detecting the ignition st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com