Simplified calculation method of radial high-temperature superconducting magnetic-suspension bearing

A magnetic suspension bearing and high-temperature superconducting technology, which is applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of difficult operation, few design schemes, and complexity, and achieve the effect of ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

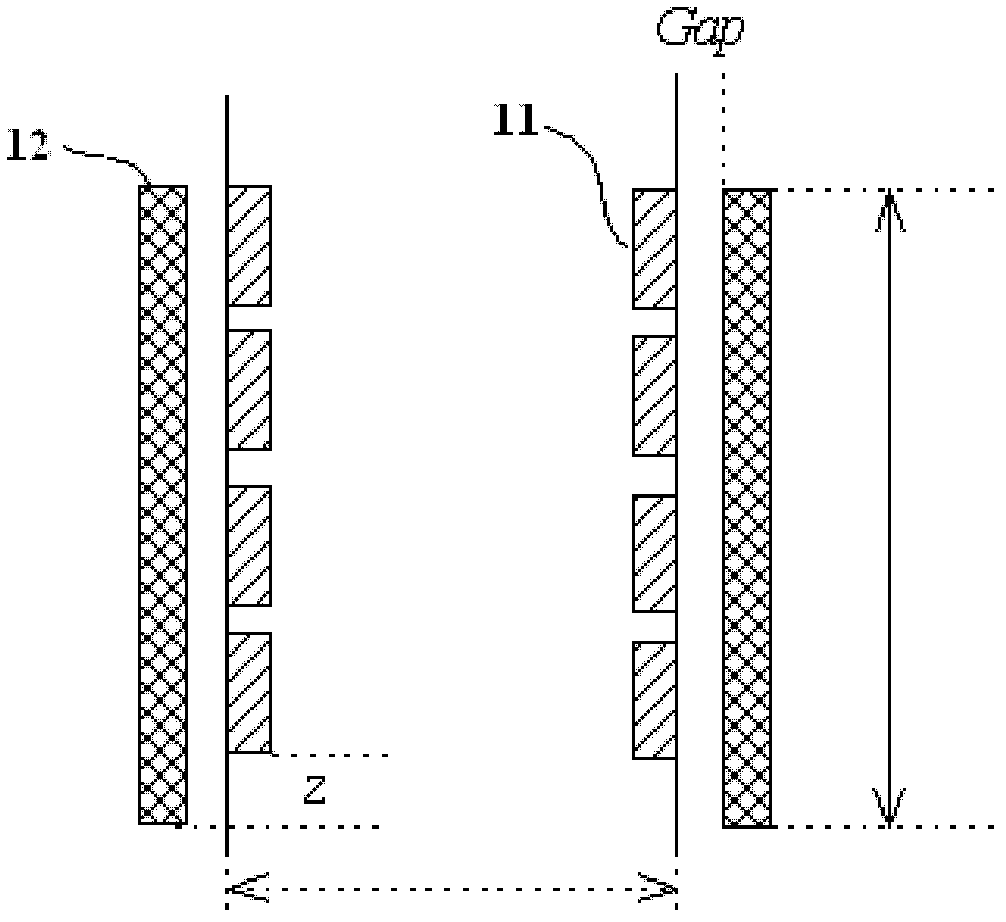

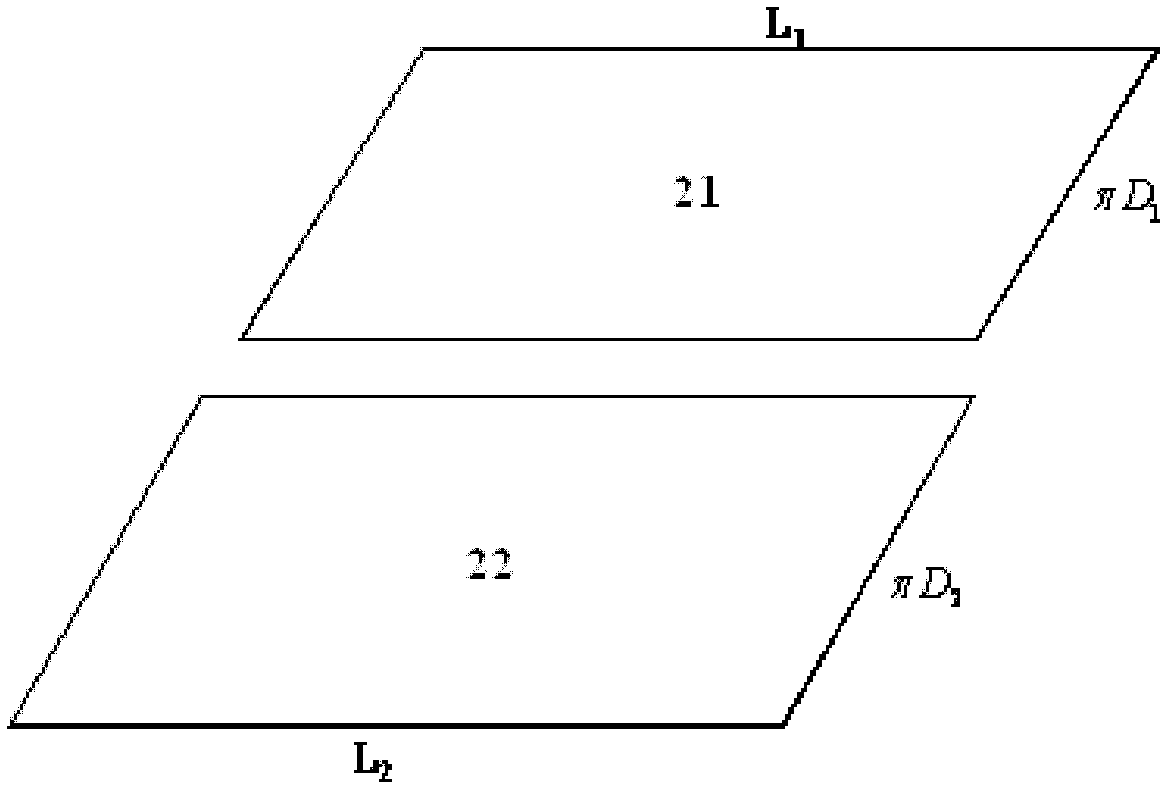

[0020] figure 1 It is a sectional view of a conventional radial high temperature super magnetic suspension bearing. Including the permanent magnet rotor 11 and the high temperature superconducting stator 12, Gap is the levitation gap between the permanent magnet rotor and the high temperature superconducting stator, and Z is the axial displacement required from cooling to stable levitation. The magnetic pole direction of the permanent magnet (N pole or S pole) is the radial direction of the radial high temperature super magnetic suspension bearing. The c-axis direction of the high temperature superconducting block is the radial direction of the radial high temperature super magnetic suspension bearing. The arrangement on the rotor of the ultra-magnetic levitation bearing is a consistent arrangement of magnetic poles. The total axial length of the permanent magnet rotor is L 1 , the outer diameter of the permanent magnet rotor is D 1 . The total axial length of the supercon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com