Hollow glass curtain wall

A glass curtain wall and hollow technology, applied to walls, building components, buildings, etc., can solve the problems of waste, the torsional mechanical properties of open profiles on the lower side are not as good as those of closed profiles, and there is no formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

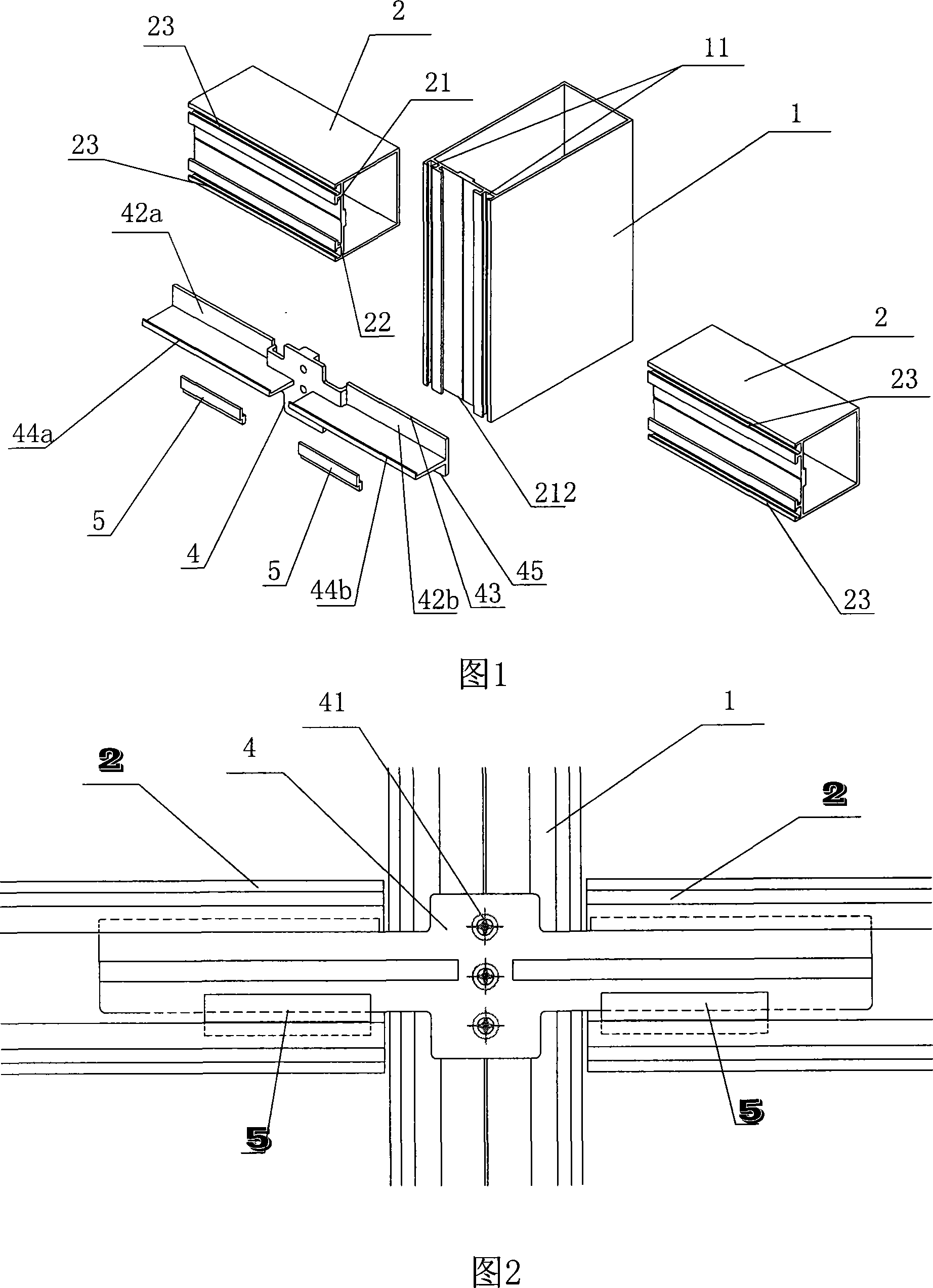

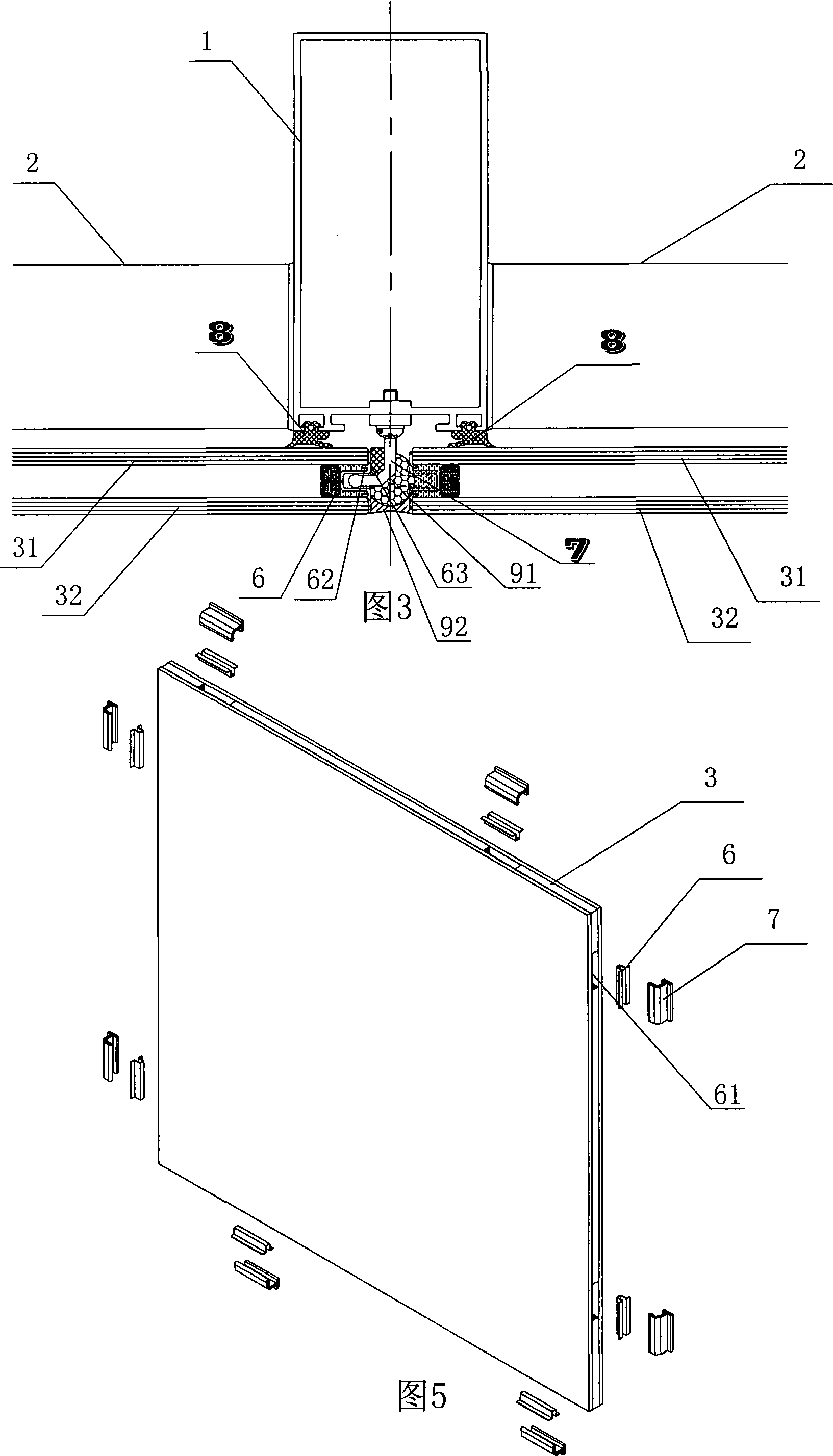

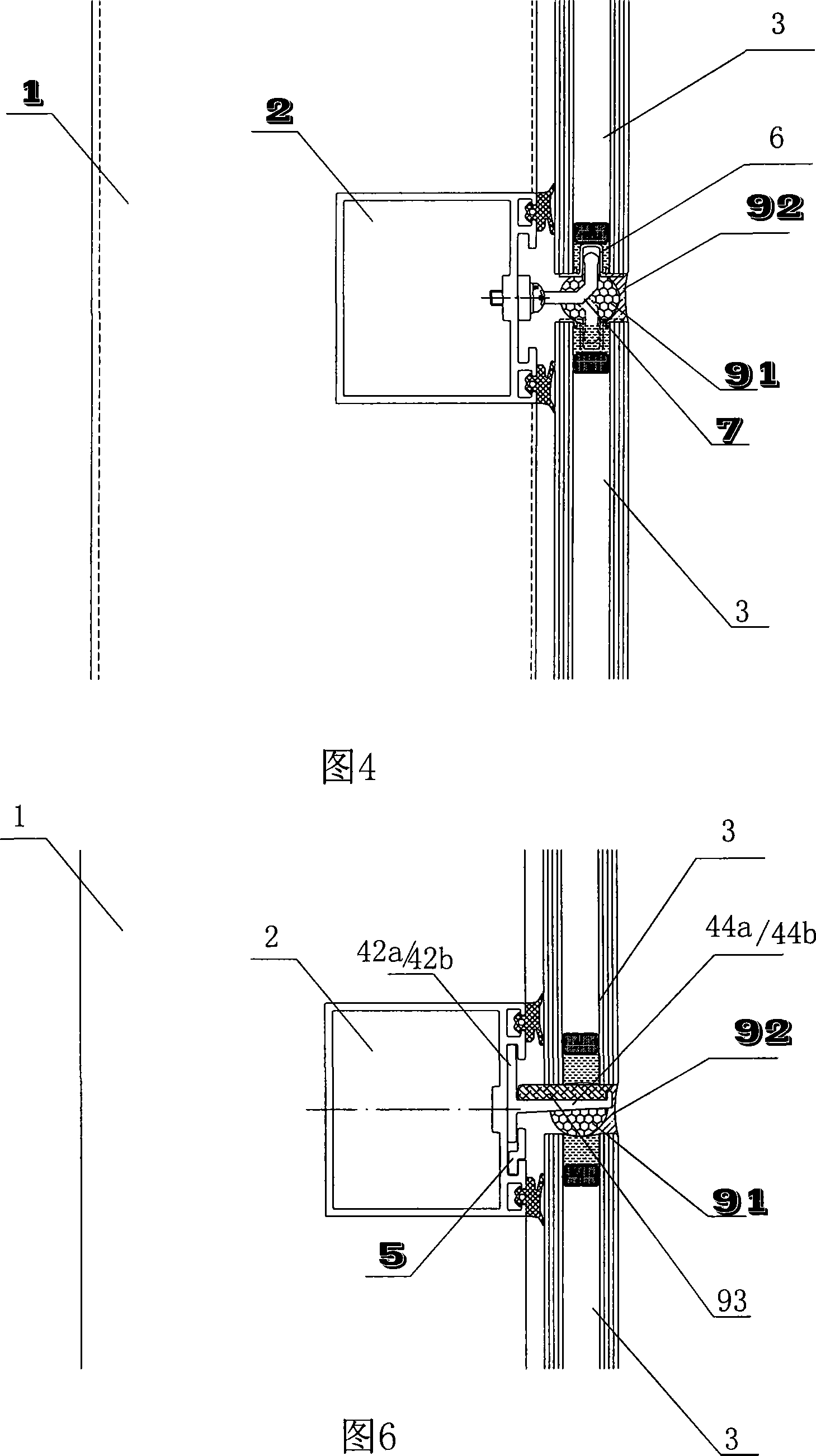

[0017] Embodiment 1, the embodiment of the hidden frame glass curtain wall, refer to the attached Figure 1-6 .

[0018] The present invention includes a column 1, a beam 2, and a hollow glass plate 3. The hollow glass plate includes an inner glass plate 31 and an outer glass plate 32. The hollow glass curtain wall is provided with a multifunctional connector 4.

[0019] The multi-functional connector is installed on the column by screws 41, the multi-functional connector has wing plates 42a, 42b connected to the beams on both sides of the column, and the front of the beam is provided with the upper edge 43 of the wing. Matching groove 21, the crossbeam is hung on the wing plate, and the multifunctional connector is also provided with supporting plates 44a, 44b of the hollow glass plates on the wing plate, and the adjacent bottom corners of the adjacent hollow glass plates arranged side by side supported on the pallet.

[0020] The present invention is also provided with a p...

Embodiment 2

[0027] Embodiment 2, the embodiment of exposed frame glass curtain wall, refer to the attached figure 1 , 2 , 7, 8, 9. The keel system of this embodiment adopts the keel system of the hidden frame glass curtain wall in Embodiment 1, Figure 7 , 8 , 9, the same reference numerals as those in Embodiment 1 represent the same meanings.

[0028] As shown in the figure, this embodiment establishes an exposed frame glass curtain wall system on the basis of the above-mentioned keel system, which will be described in detail below.

[0029] It is provided with a pressure plate 260 for the hollow glass plate, the pin slot 22 on the beam, the groove 21 that is hooked and matched with the edge of the wing plate, and the front of the beam between the above two grooves is formed as a clamping groove for the pressure plate mounting part 270 , the front of the column is also provided with a pressure plate mounting part slot 212 of the same shape as the pressure plate mounting part slot on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com