Hydraulic Seat Seal Permanent Openhole Packer and Openhole Completion Isolation Method

A packer and hydraulic technology, used in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of long construction period, limited sealing performance, low pressure differential capacity, etc., and achieve structural design. Ingenious, saving operation time and high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

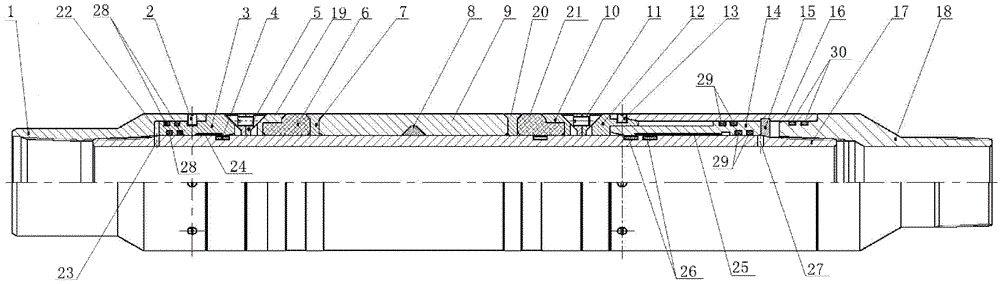

[0024] figure 1 It is a semi-sectional view of the structure of the invented hydraulic seated permanent open hole packer. Such as figure 1 As shown, the hydraulic seated permanent open hole packer includes a mandrel 17 with an axial through hole. One end of the mandrel 17 is connected to the first joint 1, and the other end is connected to the second joint 18. The joint 1 to the second joint 18 are sequentially socketed with the left push slip 3, the first metal expansion bowl 5, the first auxiliary rubber cylinder pressure ring 19, the first auxiliary rubber cylinder 6, the first spacer ring 7, the main rubber cylinder 9, The second spacer ring 20, the second auxiliary rubber cylinder 21, the second auxiliary rubber cylinder pressure ring 10, the second metal expansion bowl 11, the shear ring 12, the piston 14 and the stop ring 15; one end of the slip 3 is pushed left It is located between the first joint 1 and the mandrel 17, and is in sealing and sliding connection with t...

Embodiment 2

[0026] This embodiment is an open-hole well completion isolation method using the above-mentioned packer of the present invention. For the part related to the packer, please refer to figure 1 and the above description. The details of this embodiment are as follows: the open hole completion isolation method using the above-mentioned packer includes the following steps:

[0027] a. Connect the above-mentioned packer to the completion string, wherein the second joint of the packer is connected to the wellbore isolation valve with a ball seat through the tubing, and the first joint is connected to the tubing or drill pipe;

[0028] b. Send the packer to the downhole design position, put the sealing ball into the ball seat of the wellbore isolation valve through the drill pipe or tubing;

[0029] c. Pressing from the oil pipe or drill pipe, the pressure is transmitted to the left push slip 3 and the piston 14 respectively through the first pressure transmission hole 23 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com