Super waterproof water-borne wood paint and preparation method thereof

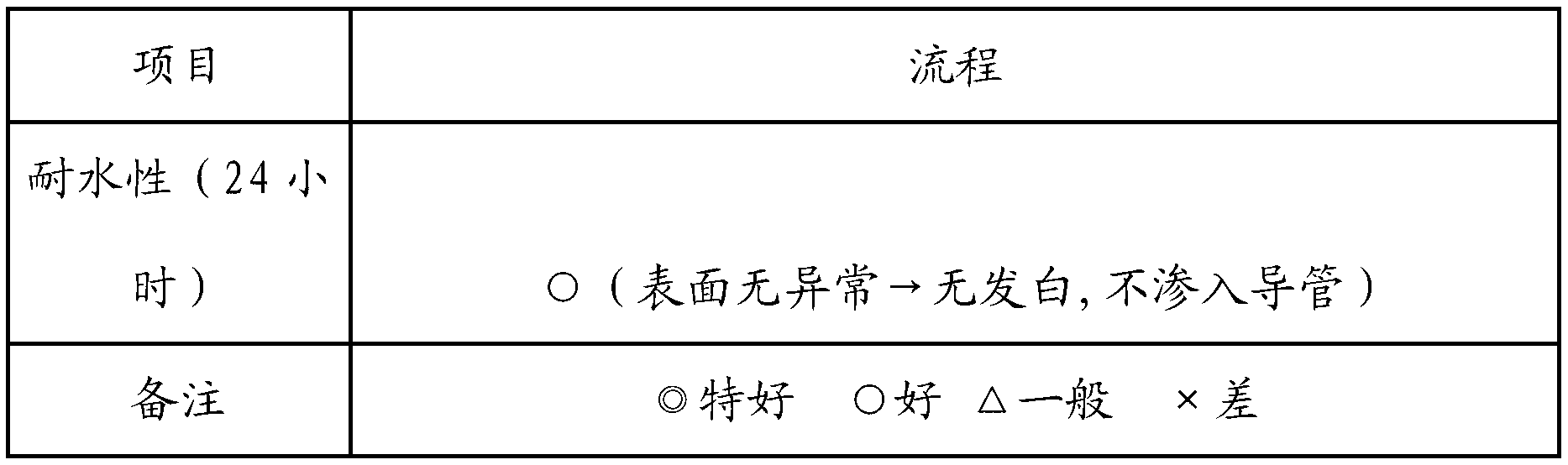

A water-based wood paint and substrate technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of wood paint film cracking, peeling, poor water resistance, etc., to ensure adhesion, excellent water resistance, The effect of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A super water-resistant water-based wood paint, comprising 10% of aliphatic polyurethane dispersion, 1.2% of defoamer, 3.5% of substrate wetting agent, 7% of dispersant, 0.6% of co-solvent, and 77% of pigment extender by mass percentage and thickener 0.7%.

[0021] The preparation process steps are as follows:

[0022] (1) First add the aliphatic polyurethane dispersion, defoamer, substrate wetting agent, dispersant, co-solvent and water into the mixer in sequence, and stir at 1000 rpm for 10 minutes;

[0023] (2) To the mixed solution prepared in step (1), add talcum powder, heavy calcium powder and silicon dioxide powder in the prescribed amount, then stir at 1000 rpm for 20 minutes until the talc Powder, heavy calcium powder and silicon dioxide powder are fully mixed with the solution;

[0024] (3) Add the thickener to the mixture obtained in step (2), and stir at 1000 rpm for 10 minutes to obtain the super water-resistant water-based wood paint.

Embodiment 2

[0026] A super-water-resistant water-based wood paint, comprising 20% of aliphatic polyurethane dispersion, 1.0% of defoamer, 2.5% of substrate wetting agent, 6.5% of dispersant, 0.5% of co-solvent, 0.5% of water, Extender pigment 68% and thickener 1%.

[0027] Preparation:

[0028] (1) First add the aliphatic polyurethane dispersion, defoamer, substrate wetting agent, dispersant, co-solvent and water into the mixer in sequence, and stir at 800 rpm for 12 minutes;

[0029] (2) To the mixed solution prepared in step (1), add talcum powder, heavy calcium powder and silicon dioxide powder in the prescribed amount, then stir at 1000 rpm for 20 minutes until the talc Powder, heavy calcium powder and silicon dioxide powder are fully mixed with the solution;

[0030] (3) Add the thickener to the mixture obtained in step (2), and stir at 1200 rpm for 8 minutes to obtain the super water-resistant water-based wood paint.

Embodiment 3

[0032] A super water-resistant water-based wood paint, comprising by weight 25% of aliphatic polyurethane dispersion, 0.8% of defoamer, 2.5% of substrate wetting agent, 6% of dispersant, 0.3% of co-solvent, 0.5% of water, Extender pigment 65% and thickener 0.5%.

[0033] Preparation:

[0034] (1) First add the aliphatic polyurethane dispersion, defoamer, substrate wetting agent, dispersant, co-solvent and water into the mixer in sequence, and stir at 1200 rpm for 10 minutes;

[0035] (2) To the mixed solution prepared in step (1), add talcum powder, heavy calcium powder and silicon dioxide powder in the prescribed amount, then stir at 1500 rpm for 15 minutes until the talc Powder, heavy calcium powder and silicon dioxide powder are fully mixed with the solution;

[0036] (3) Add the thickener to the mixture obtained in step (2), and stir at 1000 rpm for 10 minutes to obtain the super water-resistant water-based wood paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com