Strip postprocessing wire centring device and usage thereof

A centering device and post-processing technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as potential safety hazards, improve production efficiency, ensure straightness, and avoid unsafe operating behaviors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

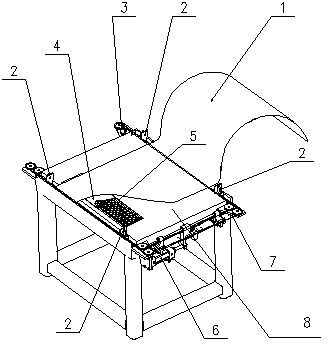

[0018] Embodiment 1, a strip post-processing line centering device, which is a four-point closing centering device, includes a centering platform, and four centering blocks 2 and fixed pulleys 3 are arranged on the centering platform and passed through The steel rope 7 is connected to the cylinder 6, and an electromagnet unit 5 is arranged on the centering platform. An insulating backing plate 4 is arranged on the electromagnet unit 5. The insulating backing plate 4 is a plastic backing plate with lines, and the lines are consistent with the operation of the unit. The direction is vertical; 100 small electromagnet units are divided into 25 groups by superposition and combination, the first group is composed of electromagnets numbered 1 to 4, the second group is composed of electromagnets numbered 1 to 8..., and so on The 25th group is composed of electromagnets numbered 1 to 100, the suction force of the 1st group to the 25th group is from small to large, and the electromagnet ...

Embodiment 2

[0021] Embodiment 2, a strip post-processing line centering device, which is a four-point closing centering device, includes a centering platform, and four centering blocks 2 and fixed pulleys 3 are arranged on the centering platform and passed through The steel rope 7 is connected with the cylinder 6, and the centering frame is provided with an electromagnet unit 5, the electromagnet unit 5 is a whole piece of electromagnet, an insulating backing plate 4 is set on the electromagnet unit 5, and the insulating backing plate 4 is a plastic backing plate And with lines, the lines are perpendicular to the running direction of the unit.

[0022] The method of using the centering device of the post-processing line of the strip: after the operation of the strip steel 1 is completed, the tail of the strip and the head of the next roll of strip steel 1 are respectively run to the front and rear of the welding machine or the sewing machine. On the centering stand, according to the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com