Radiation structure of wind driven generator

A technology of wind turbines and heat dissipation structures, which is applied in wind power generation, electrical components, electromechanical devices, etc., can solve the problem of motor heat dissipation without other auxiliary functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

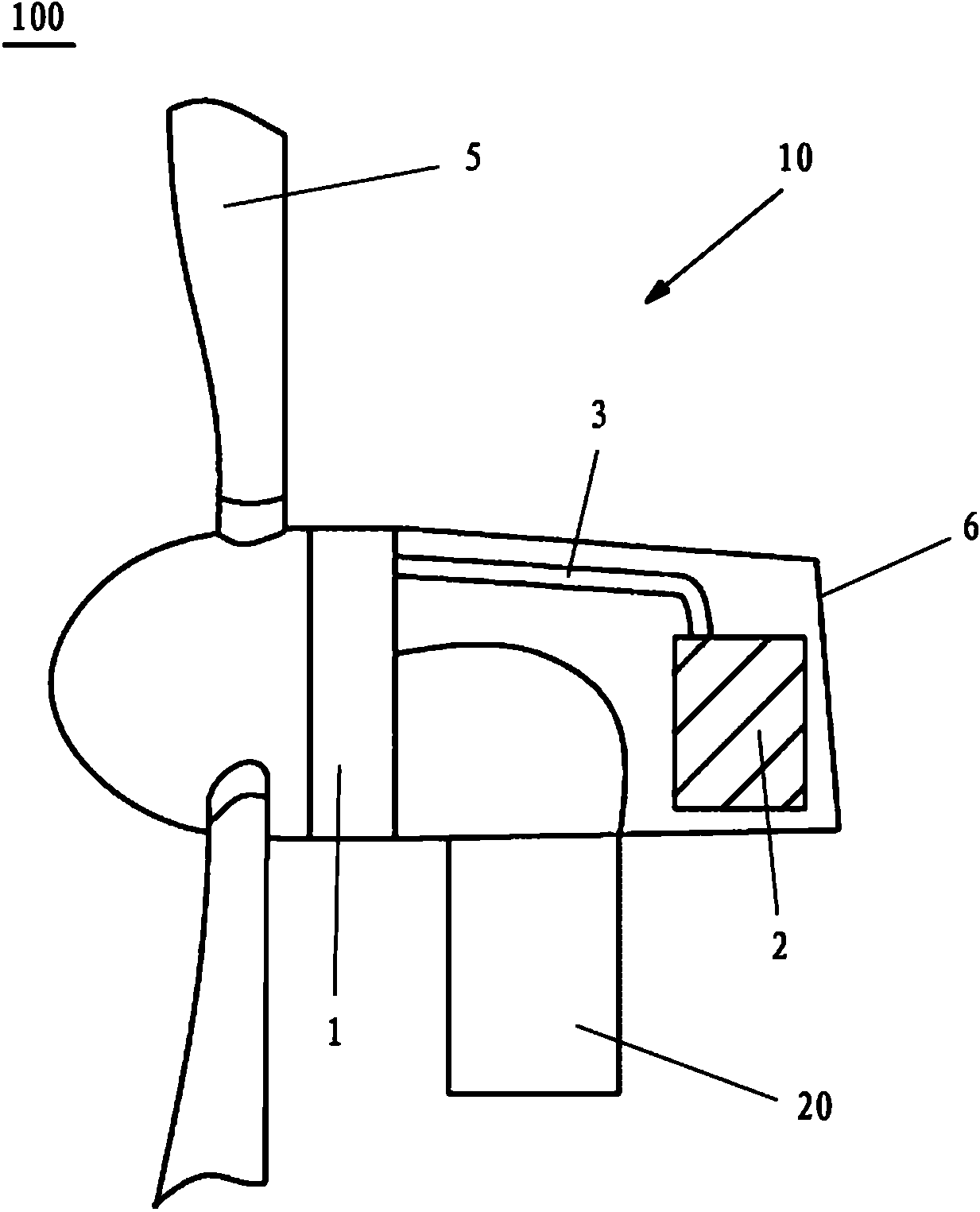

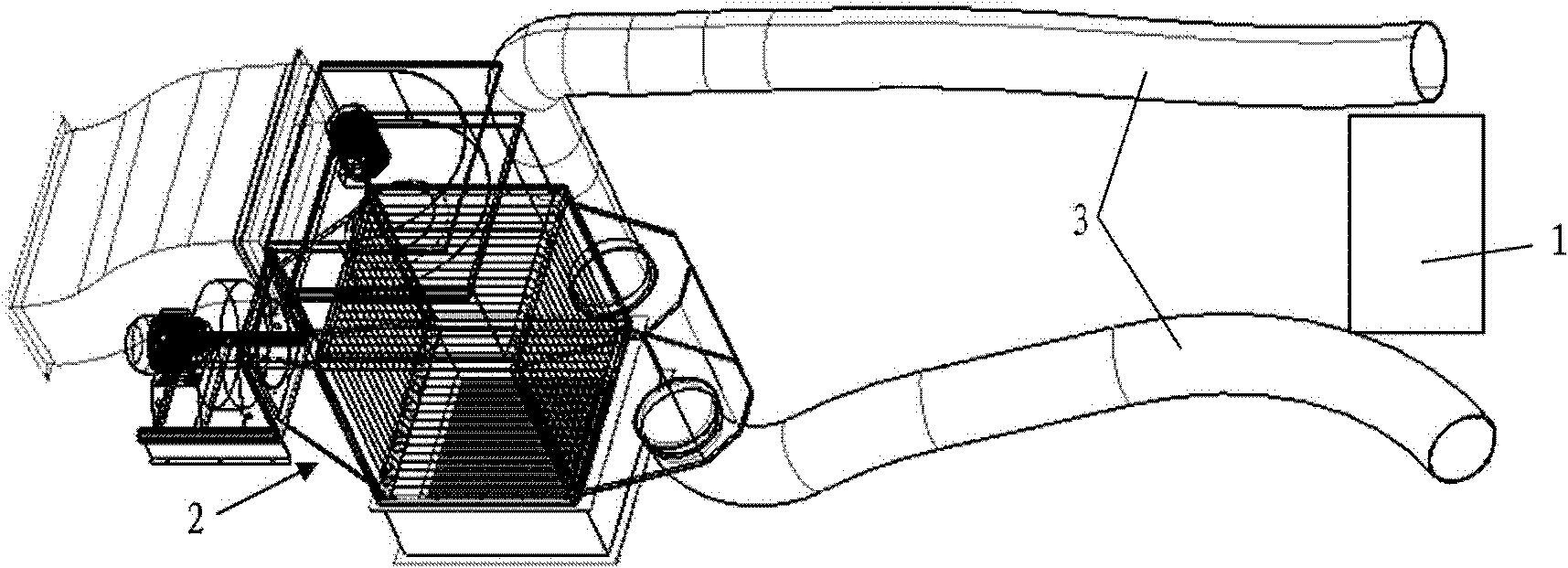

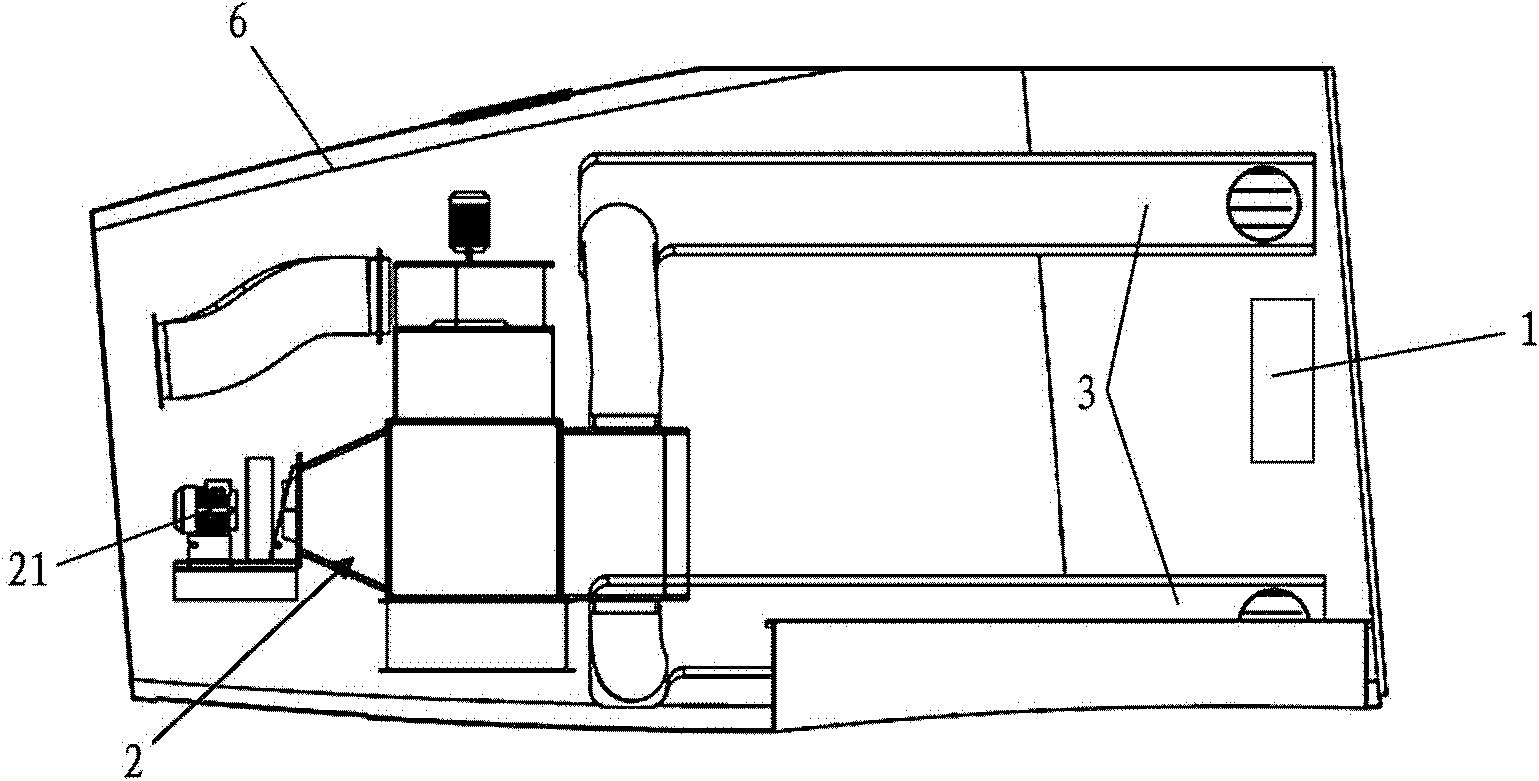

[0026] Such as image 3 As shown, the heat dissipation structure of the wind power generator according to the embodiment of the present invention includes a radiator 2 and at least one heat dissipation pipe 3 . The radiator 2 is arranged on one side of the nacelle, and the generator 1 is arranged on the other side of the nacelle. One end of the heat dissipation pipe 3 is connected with the radiator 2 and the other end is connected with the generator 1 .

[0027] The radiator 2 has a motor 21 for delivering the hot air generated in the generator 1 to the radiator 2 via the heat dissipation pipe 3 .

[0028] The following will combine Figure 4 The specific structure of the heat dissipation pipe 3 will be described in detail.

[0029] The heat dissipation duct 3 includes two parts that are combined with each other to form a cavity, wherein one part is the cabin wall 6 and the other part is the cover plate 32 . That is, the heat dissipation passage 3 is formed by combining th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com