Electron beam exposure patterning method on an insulating substrate

A technology of electron beam exposure and insulating substrate, applied in the field of microelectronics, can solve the problems of electron beam deflection, exposure pattern shift, distortion deformation, etc., and achieve the effect of solving the charge accumulation and facilitating the peeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

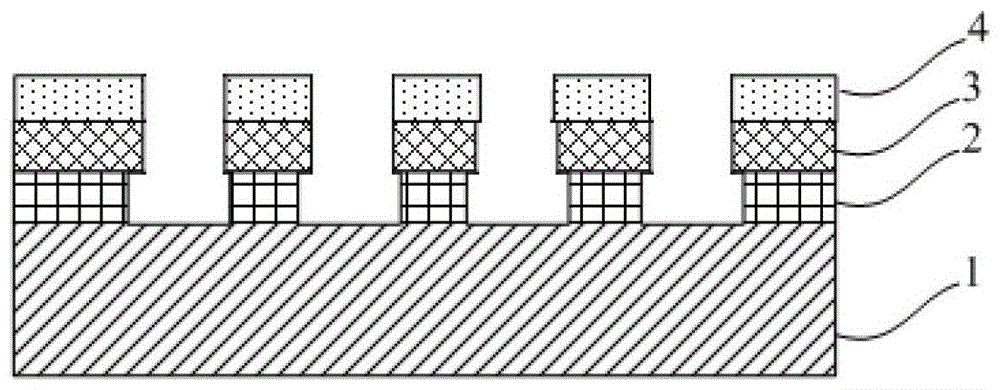

[0052] The invention provides an electron beam exposure patterning method on an insulating substrate, which specifically includes the following steps:

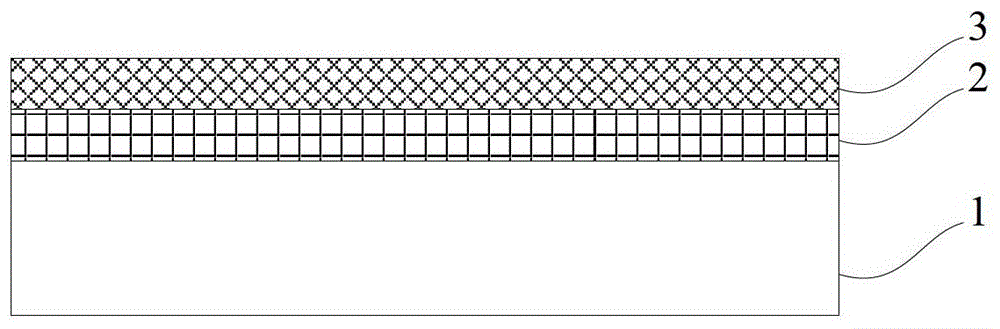

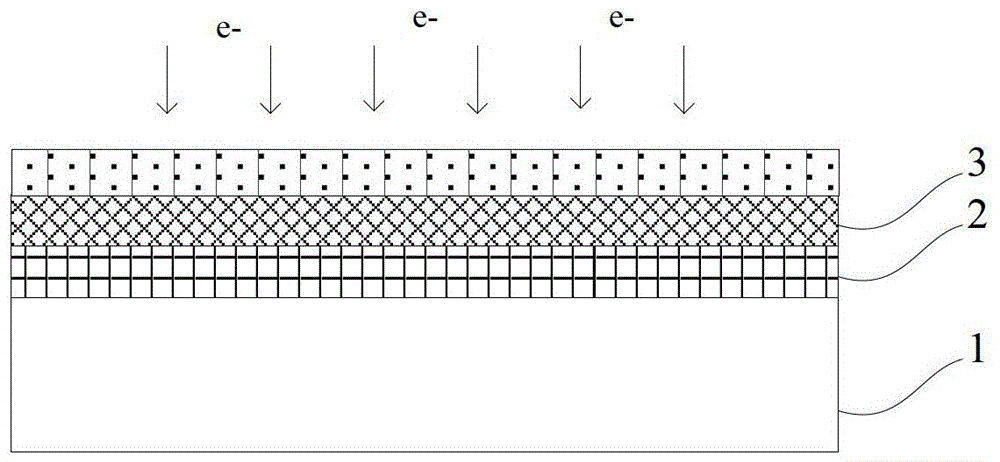

[0053] see figure 1 As shown, an insulating substrate 1 is provided, and the upper surface of the insulating substrate 1 is spin-coated with PMMA1 type electron beam photoresist 2 by using an automatic glue leveler. About 10s, then fast 4000rpm, the time is about 45s, and then it can be dried at a temperature of about 180°C. Then spin-coat PMMA2 type electron beam photoresist 3, the rotation speed is set to slow at 500rpm for about 10s, then fast at 4000rpm for about 45s, and then dried at a temperature of about 180°C. The obtained structure diagram is as follows figure 1 shown.

[0054] Wherein, the thickness of the insulating substrate can be more than 10 microns, and the material of the insulating substrate can be SiO 2 、Al 2 o 3 Or MgO, etc., in this embodiment, choose SiO 2 substrate. In this step, a cleaning st...

Embodiment 2

[0062] This embodiment provides another electron beam exposure patterning method on an insulating substrate, which specifically includes the following steps:

[0063] First, see Figure 6 As shown, an insulating substrate 10 is provided, and the PMMA1 type electron beam photoresist 20 is spin-coated by an automatic coating machine. Left and right drying, the obtained structure graph is as follows Figure 6 shown.

[0064] The thickness of the insulating substrate 10 can exceed 10 microns, and the substrate can be SiO 2 , Al2O 3 , MgO, etc., in this embodiment, preferably SiO 2 substrate. Before this step, a cleaning step of the insulating substrate 10 is also included. In this embodiment, a standard RCA process is used to clean the SiO 2 substrate.

[0065] Next, deposit metal thin film 40 on the insulating substrate 10 of spin-coating PMMA1 type electron beam photoresist 20, then adopt automatic glue leveling machine to spin coat PMMA2 type electron beam photoresist 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com