Fatigue test device and method for axle

A fatigue test and test device technology, applied in the field of rail transit, can solve the problems of not being able to carry out the fatigue test of the axle neck and not being able to comprehensively evaluate the rationality of the wheel and axle structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

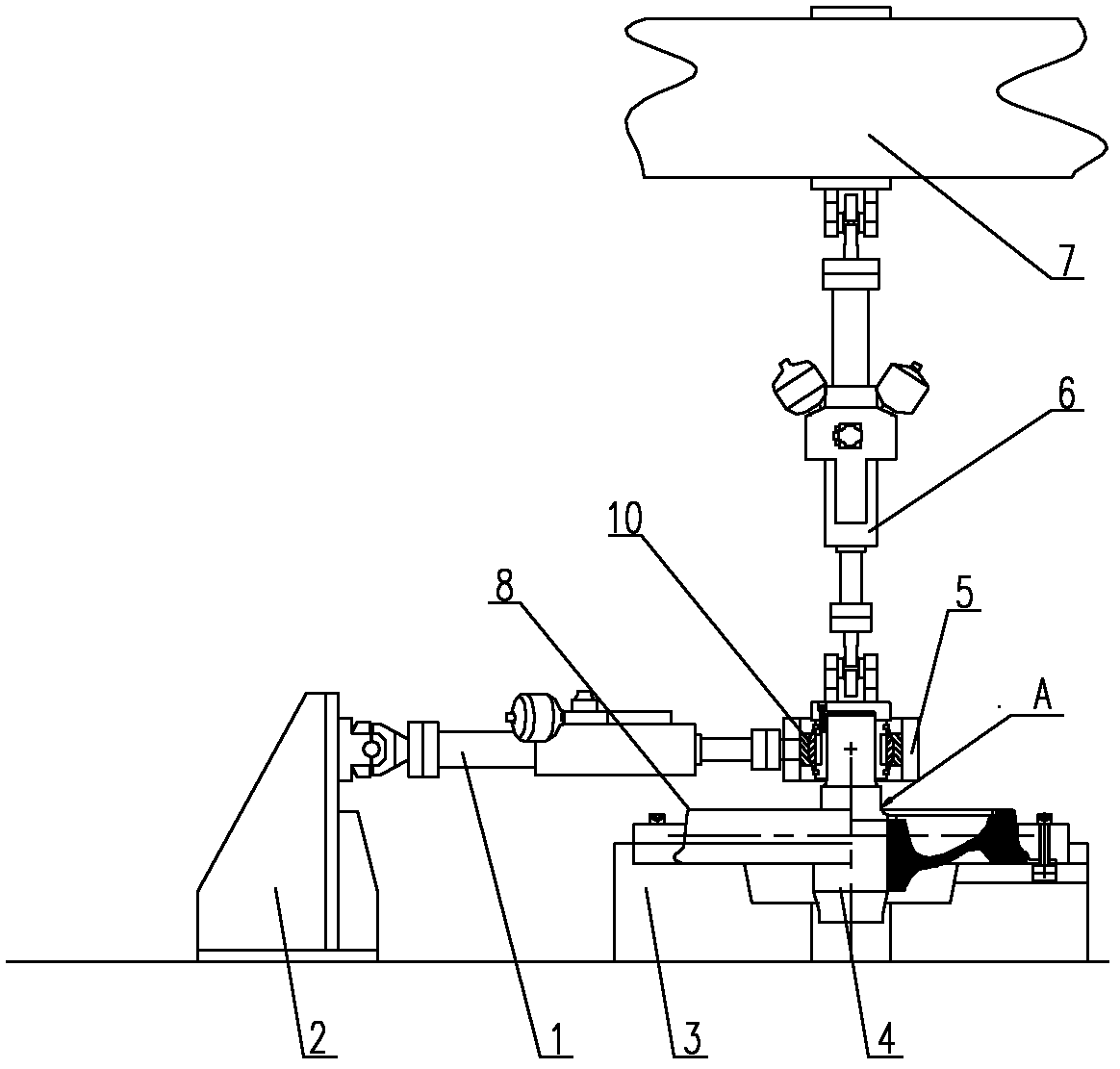

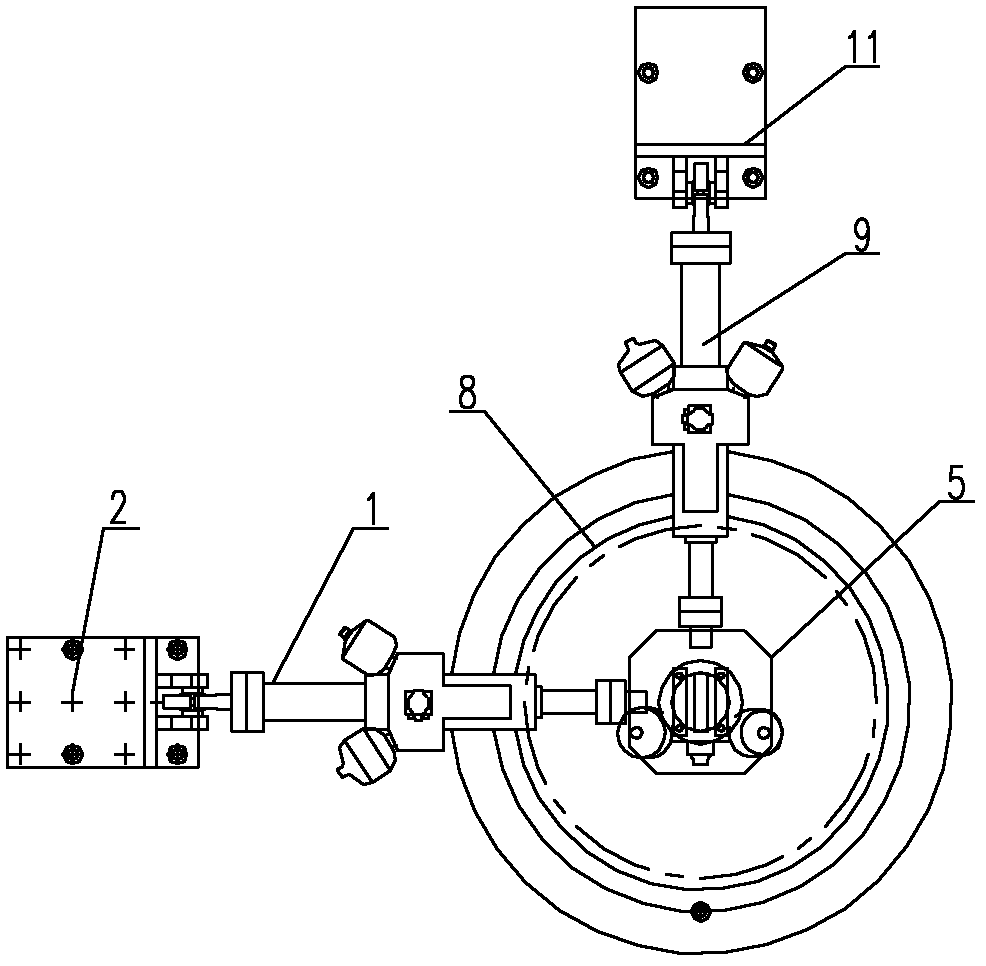

[0036] Example 1, such as figure 1 and figure 2 As shown, the test device for realizing the fatigue test method of the axle journal mainly includes a loading beam 7 and a platform 3 . in,

[0037] radially fix the wheel 8 on the platform 3, and axially fix the end of the tested wheel shaft 4;

[0038] At the journal of the tested wheel shaft 4, the rolling bearing 10 is installed inside the mounting seat 5, and the vertical actuator 6, the transverse actuator 1 and the longitudinal actuator 9 are respectively connected to the mounting seat 5.

[0039] The axle journal fatigue test method is to paste a stress detection sheet at the corner of the tested wheel axle 4 adjacent to the wheel 8;

[0040] During the journal fatigue test, the tested wheel shaft 4 rotates at a uniform speed in the circumferential direction, and the above-mentioned vertical actuator 6, lateral actuator 1 and longitudinal actuator 9 apply loads to the journal of the tested wheel shaft 4 respectively....

Embodiment 2

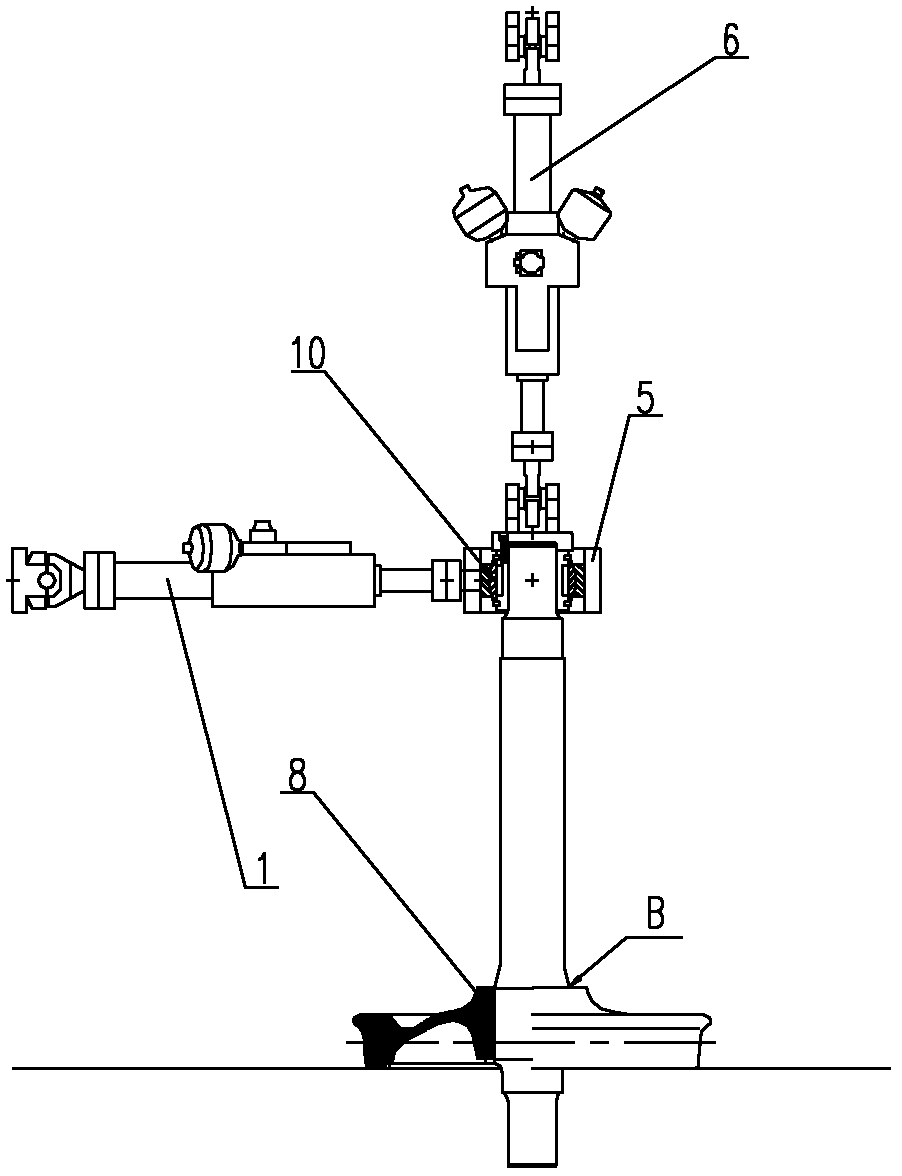

[0046] Example 2, such as image 3 As shown, the difference from Example 1 is that during the shaft fatigue test, the shaft end of the tested wheel shaft 4 is installed inside the mounting seat 5 through the rolling bearing 10, and the vertical actuator 6 and the lateral actuator 1 and the longitudinal cylinder 9 are connected to the mounting base 5 respectively.

[0047] Other test devices and test methods are similar to those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com