Coal mining machine with double-motor-driven traction section

A dual-motor drive and traction unit technology, which is applied in earthwork drilling, slitting machinery, propulsion, etc., can solve problems such as insufficient traction power, achieve simple and compact structure, ensure safe production conditions, and improve mining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings.

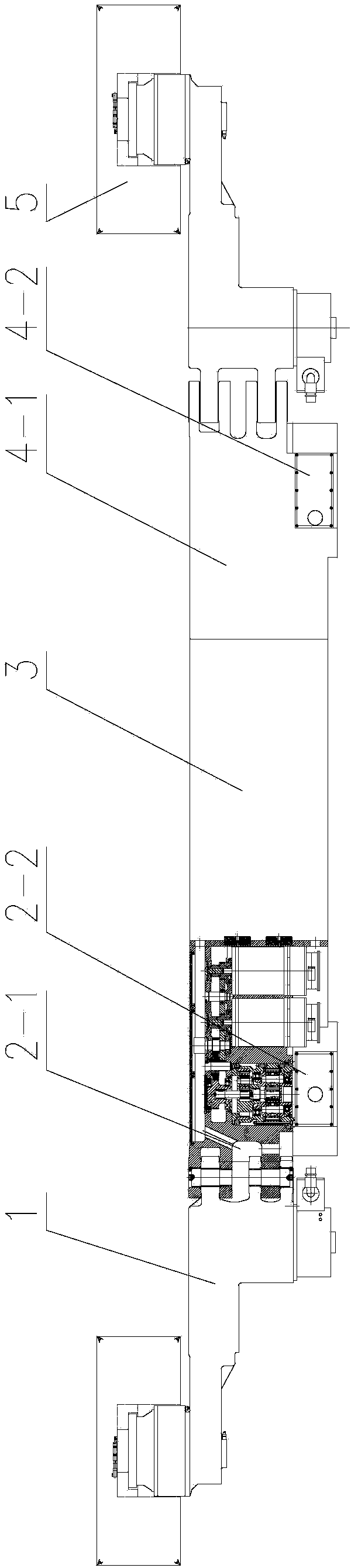

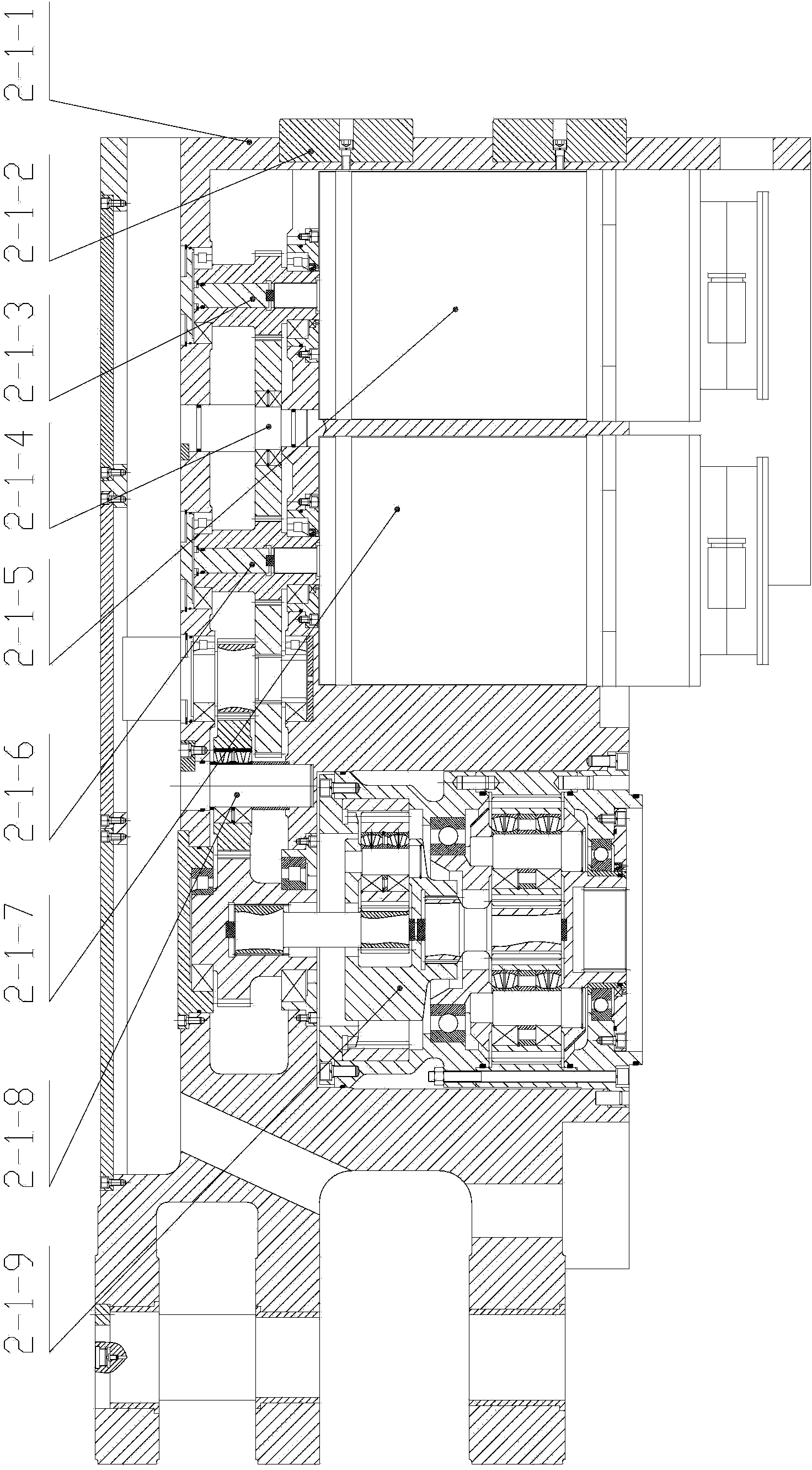

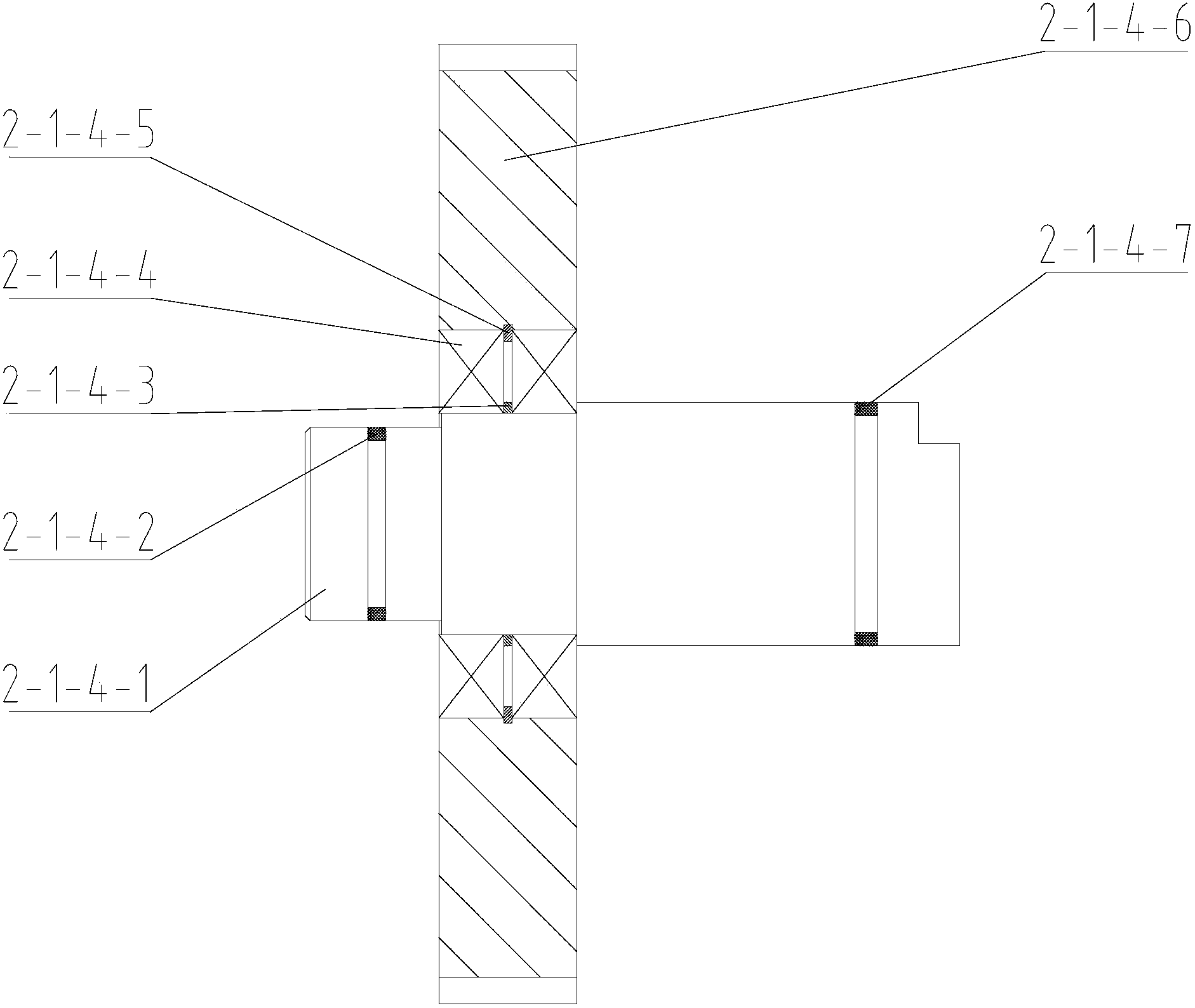

[0016] like Figures 1 to 3 As shown, the double-motor driven traction section coal shearer of the present invention includes a left cutting section 1 , a left traction section, a middle box 3 , a right traction section and a right cutting section 5 .

[0017] The left traction part and the right traction part are respectively arranged on the left and right sides of the middle box 3, the left traction part comprises a left fixed box 2-1 and a left travel box 2-2, and the right traction part comprises a right fixed box 4-1 And right walk box 4-2. Both the left end of the left fixed box 2-1 and the right end of the left cutting part 1 and the right end of the right fixed box 4-1 and the left end of the right cutting part 5 are hinged. Between the bottom of the left fixed box 2-1 and the upper end of the left traveling box 2-2, between the bottom of the right fixed box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com