Pre-treatment method for eliminating or reducing siloxane and color material in biogas

A pretreatment and siloxane technology, applied in biological sludge treatment, sludge treatment, chemical instruments and methods, etc., to achieve intelligent analysis and control, expand technical advantages and market acceptability, and reduce biogas purification treatment cost effect

Active Publication Date: 2013-06-26

国翔航天环保科技(集团)有限公司

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0024] Example 2:

Embodiment 2

[0026] Example 3:

Embodiment 3

[0028] Example 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

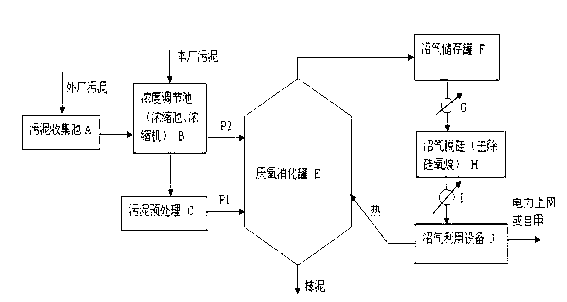

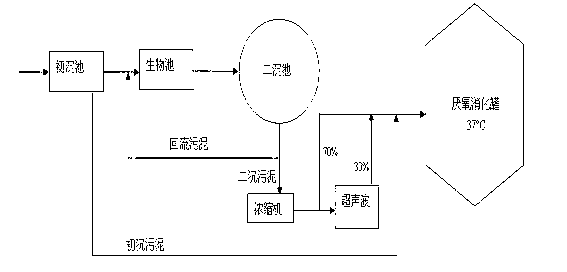

The invention relates to the technical field of sewage treatment, in particular to a pre-treatment method for eliminating or reducing siloxane and color materials in biogas. The method comprises the following steps: firstly making sludge enter into a concentration regulation pool; adjusting the concentration of the sludge; dividing the adjusted sludge into two portions, wherein one portion of the sludge directly enters into an anaerobic digestion tank and the other portion of the sludge is pre-treated firstly and then enters into the anaerobic digestion tank to perform anaerobic digestion reaction in the anaerobic digestion tank; making the produced biogas enter into a biogas storage tank, desilicating the biogas, and finally removing the siloxane in the biogas and making the biogas enter into a biogas utilization device. By adopting the technical scheme, the siloxane and color materials in the biogas are eliminated or reduced, the biogas utilization device is protected, the biogas purification treatment cost and the maintenance cost of the biogas utilization device are reduced; the intelligent analysis and control are realized, and the technical advantage and market acceptability of the sludge anaerobic digestion process technology are expanded.

Description

technical field [0001] The invention relates to the field of sewage treatment, and relates to a method for pretreating sludge partially or completely by physical or chemical methods to effectively reduce the concentration pretreatment of siloxane and chromatic substances in biogas produced by anaerobic digestion of sludge . [0002] Background technique [0003] Anaerobic digestion is a common form of sludge treatment in production practice, and one of its products is renewable energy biogas, whose main components are methane and carbon dioxide, in addition to carbon monoxide, hydrogen, ammonia, oxygen, siloxane and various Chromatic matter. Chromatic substances include alcohols, alkanes, fats, benzene, phenols, acids and other substances. Siloxane is an important part of the alkanes, and it is the most important alkanes in terms of its influence on the quality of biogas, because silicon When oxane is burned, silicon dioxide crystals will be formed. Silicon dioxide cryst...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/00C02F11/04

CPCY02E50/30

Inventor 杨顺生

Owner 国翔航天环保科技(集团)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com