Surface treatment wastewater reuse treatment process

A treatment process and surface treatment technology, which is applied in the field of surface treatment wastewater reuse treatment process, can solve the problems of difficulty in meeting the standard and high cost of surface treatment wastewater reuse, achieve low operating costs, save civil engineering costs, and improve resistance Effect of Shock Load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

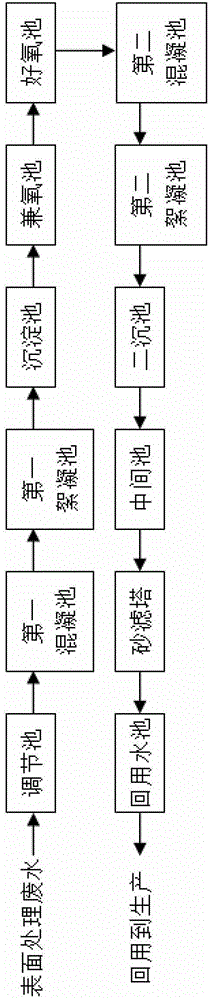

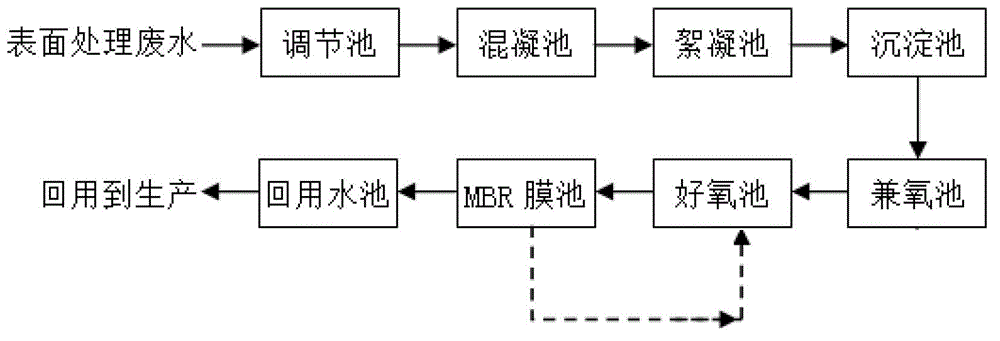

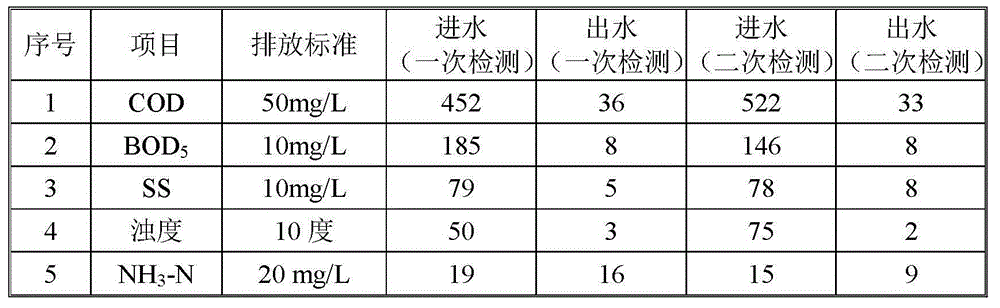

[0021] Embodiment: a kind of surface treatment waste water reuse treatment process, carry out according to the following steps:

[0022] A. Add sodium hydroxide to the rapidly stirred coagulation tank to adjust the pH value to 7-8, and add coagulant polyaluminum chloride (PAC) to make the pollutants in the wastewater react with PAC to form sediment , and then add the flocculant polyacrylamide (PAM) into the slow-stirring flocculation tank to convert the acrylic resin and other organic pollution suspended particles and colloids in the wastewater into large suspended particles visible to the naked eye.

[0023] B. The wastewater treated in step A flows into the sedimentation tank again, and the suspended matter sinks to the bottom of the tank to separate the solid and liquid by utilizing the descending sedimentation speed greater than the rising speed of the water flow.

[0024] C. The effluent from the sedimentation tank flows directly into the biochemical pool for biochemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com