Large frictional force wheel

A friction and wheel technology, applied in vehicle parts, tire parts, anti-skid devices, etc., can solve the problems of rider danger, personal injury, easy slippage, etc., and achieve the effect of reasonable length setting, convenient production and convenient selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

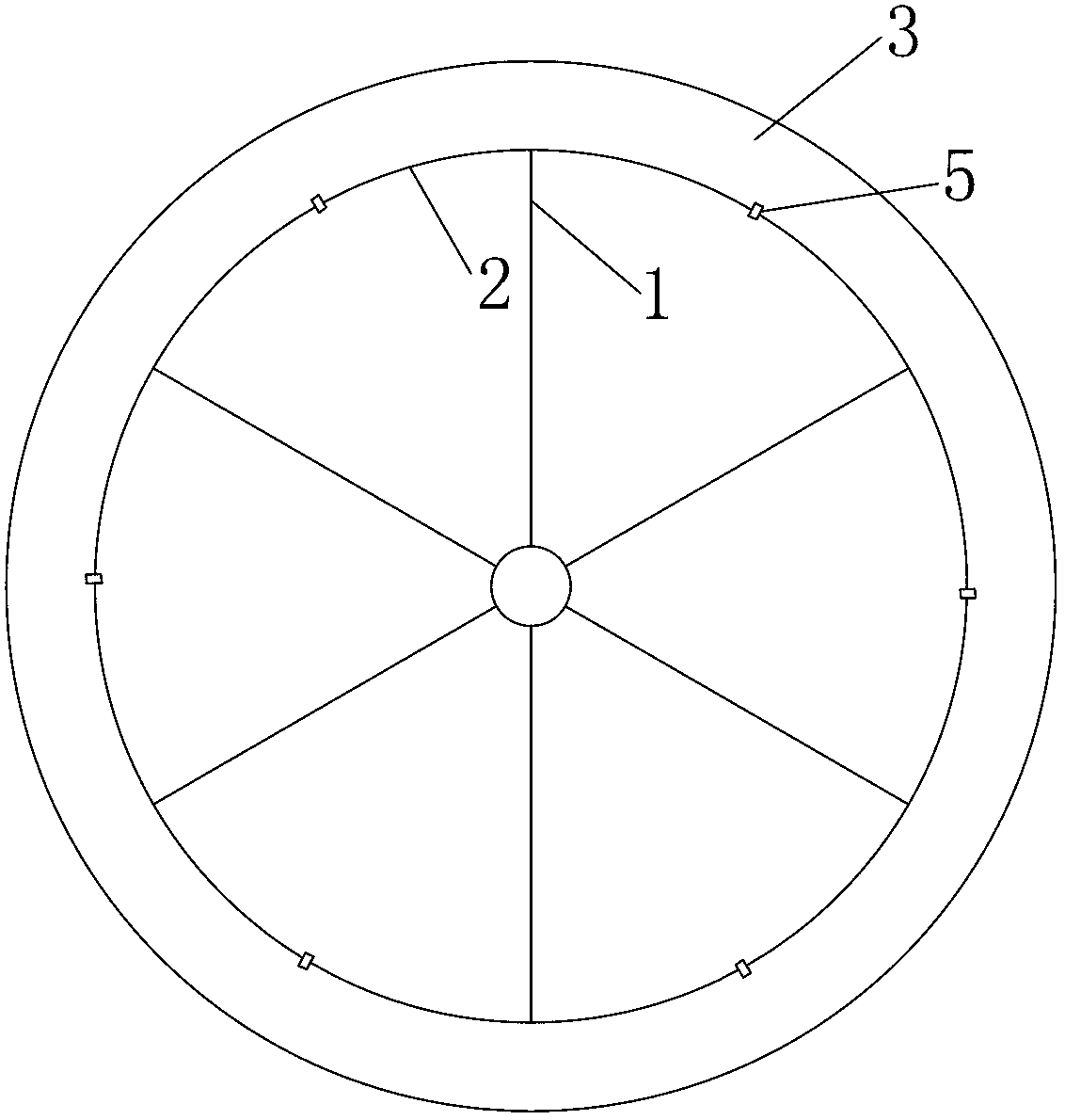

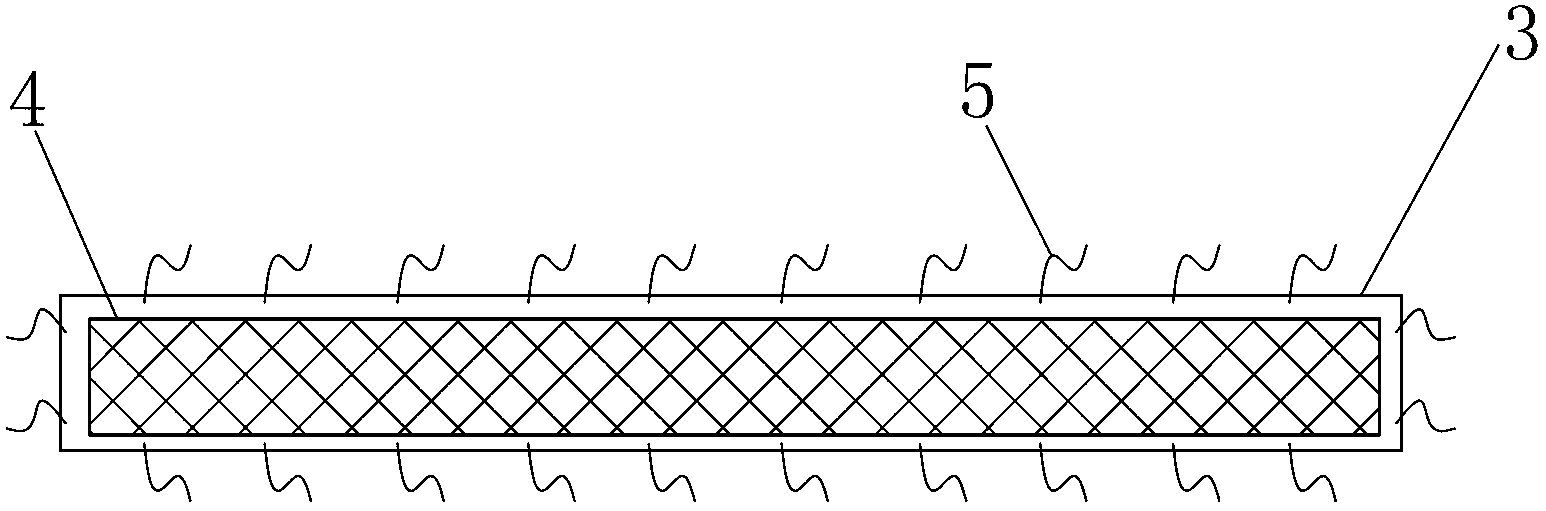

[0017] Embodiment: a kind of big friction force wheel, as figure 1 , 2 As shown, it includes a wheel hub 1 and a tire 2, and the tread of the tire 2 is coated with an anti-skid belt 3 with rough inner and outer surfaces. The anti-skid belt 3 is elongated. Made of cloth or old clothes, the length of the anti-skid belt 3 is the same as the outer circumference of the tire 2, and a plurality of cloth strips 5 are evenly sewn along the periphery of the anti-skid belt 3, and the length of the cloth strips 5 is 3cm. The anti-skid belt 3 is bound on the wheel hub 1 by cloth strips 5, and the inner and outer surfaces of the anti-skid belt 3 are coated with a layer of fiber mesh belt 4.

[0018] After use, the cloth strip 5 is untied, and the anti-skid belt 3 is taken off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com