Tile preparing method and tile manufacturing system enabling ink jet patterns and die textures to be completely matched

A preparation system and inkjet technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of not taking into account the matching of inkjet patterns and brick textures, and the inability of ceramic tiles to achieve realistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

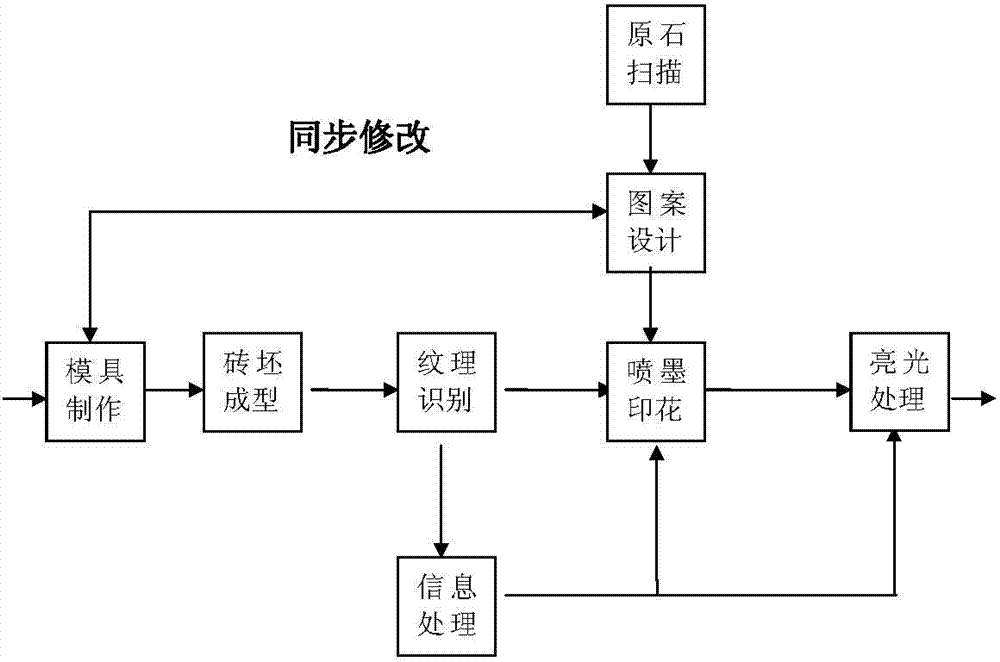

[0037] figure 1 It is a schematic diagram showing the steps of the ceramic tile preparation method for completely matching the inkjet pattern with the mold texture according to the present invention. Such as figure 1 As shown, the ceramic tile preparation method of the present invention that completely matches the inkjet pattern with the mold texture includes first scanning a plurality of natural rough stones with textures (for example, concave-convex textures), so as to obtain multiple patterns with the corresponding textures . In order to obtain a clear pattern, which is conducive to the subsequent production of accurate molds, and to facilitate the matching between the mold texture and the inkjet pattern, it is necessary to scan multiple natural rough stones with concave-convex textures in a one-to-one ratio with high precision. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com