Full-automatic numerical control sander

A grinding machine and fully automatic technology, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc., can solve the problems of unguaranteed product quality, high labor intensity of workers, and high cost of parts processing, so as to reduce the labor of workers Intensity and production cost, improving the production environment, and improving the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

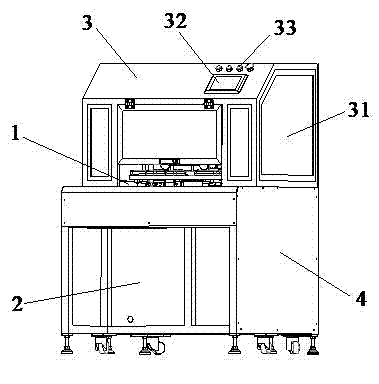

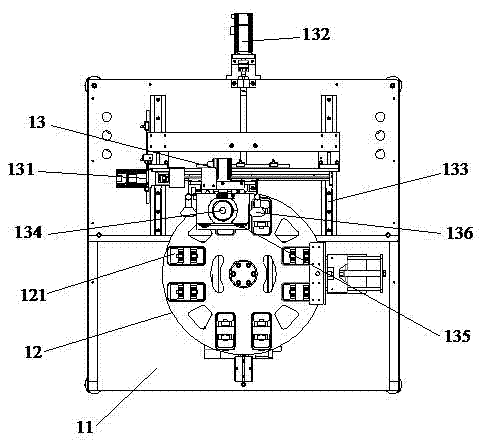

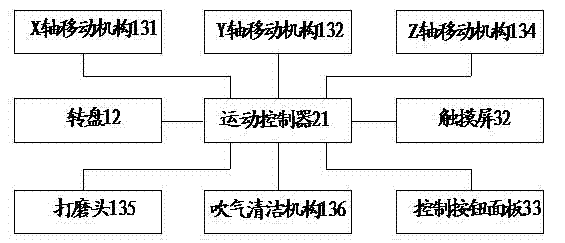

[0019] Example figure 1 , 2 , 3, 4 and 5, a full-automatic numerical control grinding machine includes a workbench 1, an electric control system 2, a top cover 3 and a bottom frame 4, the electric control system 2 is arranged inside the bottom frame 4, and the workbench 1 is set On the bottom frame 4, the top cover 3 is covered on the workbench 1, the side of the top cover 3 is provided with a transparent side window 31, and the top cover 3 is also provided with a touch screen 32 and a control button panel 33, the workbench 1 includes a support base plate 11, a turntable 12 installed on the support base plate 11, and a grinding mechanism 13, the surface of the turntable 12 is provided with an accessory fixture 121, and the grinding mechanism 13 is set as a gantry structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com