Turntable type high-speed reeling machine control method and system of cold continuous rolling production line

A control method and production line technology, which is applied in the field of electrical control, can solve the problems of unstable control of strip steel tension and difficulty in precise control of coil diameter calculation, and achieve the effect of high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

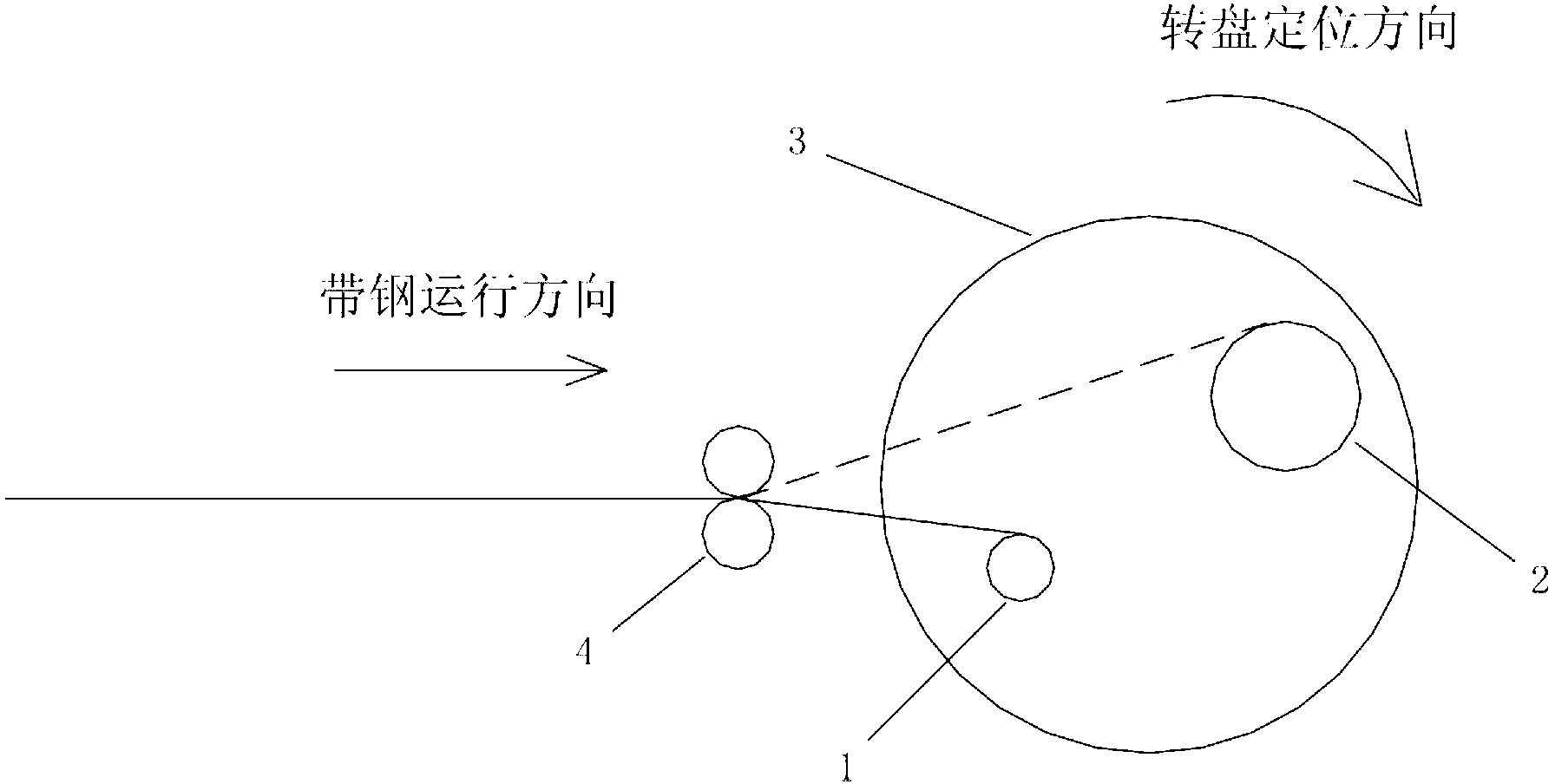

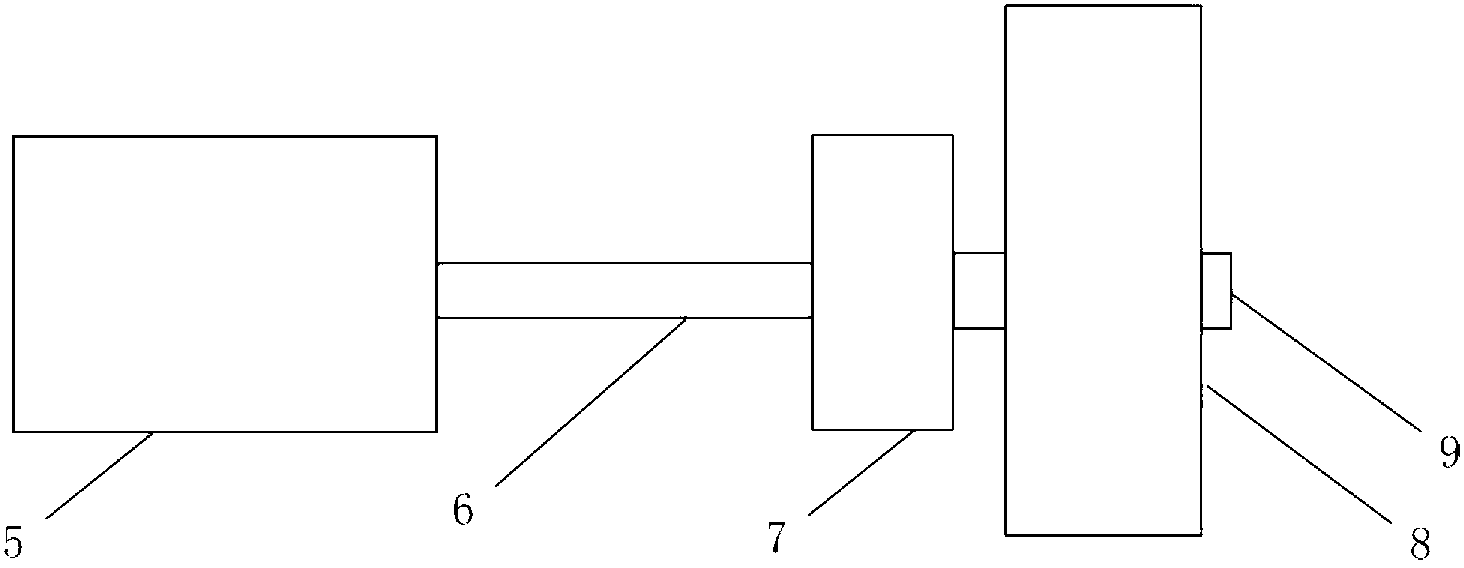

[0074] refer to Figure 1 ~ Figure 2 As shown, the control method for the rotary high-speed coiler of the cold tandem rolling production line described in the present invention is an advanced control method for the coiler of the cold tandem rolling production line, which specifically includes the following steps:

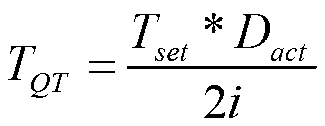

[0075] (1) Obtain the actual coil diameter D of the finished steel coil act

[0076] In order to ensure the quality of the finished steel coil, the constant tension control of the coiler is the key. In order to control the tension accurately, the trouble-free continuous calculation of the coil diameter is particularly important. The actual coil diameter of the finished steel coil is realized through two steps of calculation and correction:

[0077] ①Calculation: Before the coil diameter calculation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com