Automatic water replenishing device and potted plant container

A technology for automatic water replenishment and potted container, which is applied to automatic watering devices, container cultivation, gardening, etc., can solve the problem of not being able to automatically replenish water for a long time, and achieve the effects of simple and convenient automatic water replenishment, low processing cost and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

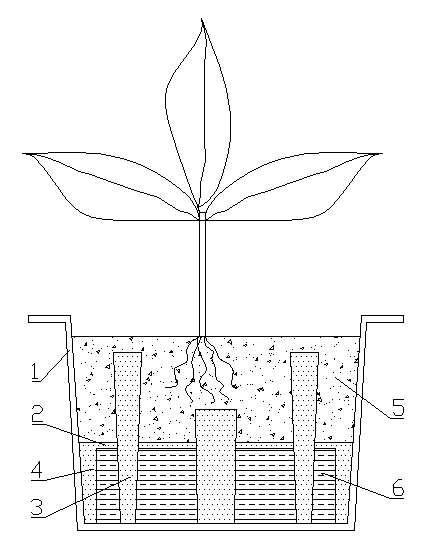

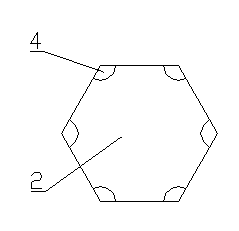

[0031] figure 1 It is a potting container with an automatic water supply device of the present invention, which includes a pot body 1, and a water-permeable partition 2 horizontally arranged in the pot body 1, and the water-permeable partition divides the pot body 1 into the upper part. The planting area 5 and the water storage area 6 located at the lower part, the support legs 4 supporting the permeable partition 2 are set in the water storage area 5; the support legs 4 in this embodiment are integrally formed with the permeable partition 2 ,like figure 2 shown. It also includes at least one water replenishing element 3 pierced through the permeable partition 2, and the two ends of the water replenishing element 3 are respectively arranged in the planting area 5 and the water storage area 6; more can be set according to the water-loving degree of the plants to be planted. The water replenishing parts 3, in this embodiment, five water replenishing parts 3 are set, four of w...

Embodiment 2

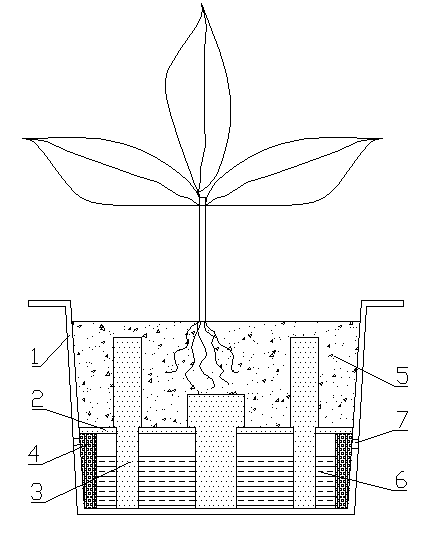

[0052] The structure of the potted container in this embodiment is basically the same as that in Embodiment 1, and its difference is:

[0053] like image 3 As shown, the pot body 1 of this embodiment is an ordinary ceramic potting container, which is provided with vent holes 7 on the side wall. The supporting legs 4 and the permeable partition 2 are not integrally formed, and the material of the supporting legs 4 may be different from that of the permeable partition 2 . The water supply part 3 is a stepped shaft with one end thick and the other end thin, and the shoulder of the water supply part 3 is clamped on the permeable partition 2 .

[0054] The aggregate of the water supply component 3 is a mixture of slag and ceramsite in a weight ratio of 3:1, the particle size of the slag is 1-5 mm, and the particle size of the ceramsite is 0.1-0.85 mm.

[0055] The water replenishment part 3 is made by the following method:

[0056] a. Mix the above-mentioned aggregate particle...

Embodiment 3

[0065] The structure of the potting container in this embodiment is basically the same as that in Example 1, the difference being that the silica sand particles of the pot body 1 are coated with a hydrophobic substance, and the hydrophobic substance is coated on the silica sand particles A hydrophobic resin film on the surface, the hydrophobic resin film is a hydrophobic phenolic resin, and the particle size of the silica sand is 0.075-0.3 mm. The hydrophobic phenolic resin is 1wt% of the silica sand particles. The hydrophobic phenolic resin is prepared by copolymerizing maleic anhydride and sodium vinyl sulfonate.

[0066] The method that described phenolic resin is coated on described silica sand particle is:

[0067] 1) Heat the phenolic resin to a molten state;

[0068] 2) When heating the silica sand particles to 220°C, add the phenolic resin and stir for 60 seconds to make the phenolic resin evenly dispersed on the surface of the silica sand particles;

[0069] 3) Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com