Online cable surface defect detection device and online cable surface defect detection method

A detection device and detection method technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as hidden product quality, difficulty in detecting cable surface defects and damage, affecting air blowing laying of optical cables, etc., to achieve convenient use and operation, and reasonable settings , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

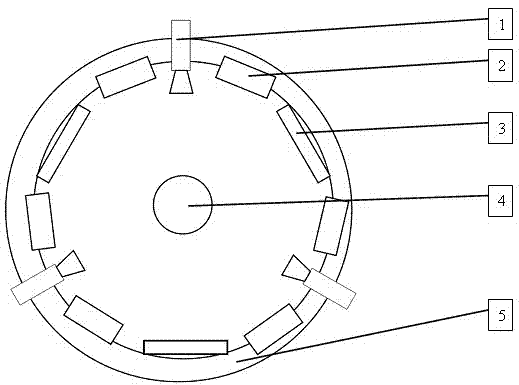

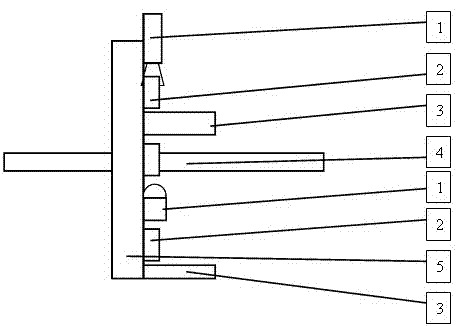

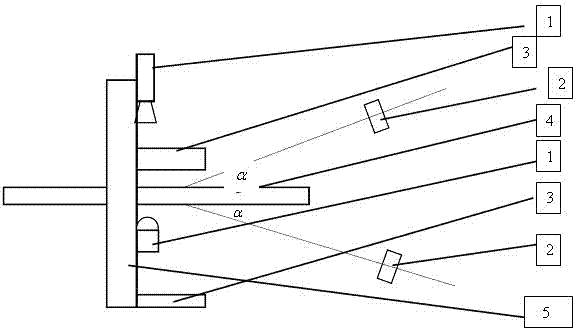

[0019] The first example is figure 1 , 2 As shown, there is an annular fixed bracket 5, the middle part of the annular fixed bracket is the position of the tested cable 4, and three cameras 1 are evenly distributed along the circumferential direction on the annular fixed bracket, and each camera is circumferentially spaced at 120°. The camera is a digital camera, and the center line of the camera lens intersects with the axis of the cable under test and is perpendicular to the axis; a light source 2 is respectively arranged on the left and right sides of each camera, and the light source is an LED surface light source, and the light emitting surface of the light source Parallel to the axis of the cable under test (the light is irradiated vertically), 6 LED surface light sources are arranged along the circumference for lighting around the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com