Non-contact high-power light-emitting diode (LED) junction temperature test method

A test method, non-contact technology, applied in the direction of single semiconductor device test, thermometer, measuring device, etc., can solve the problems of high sampling speed and complicated operation, and achieve the effect of easy practical use, simple operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in combination with diagrams and specific implementation methods.

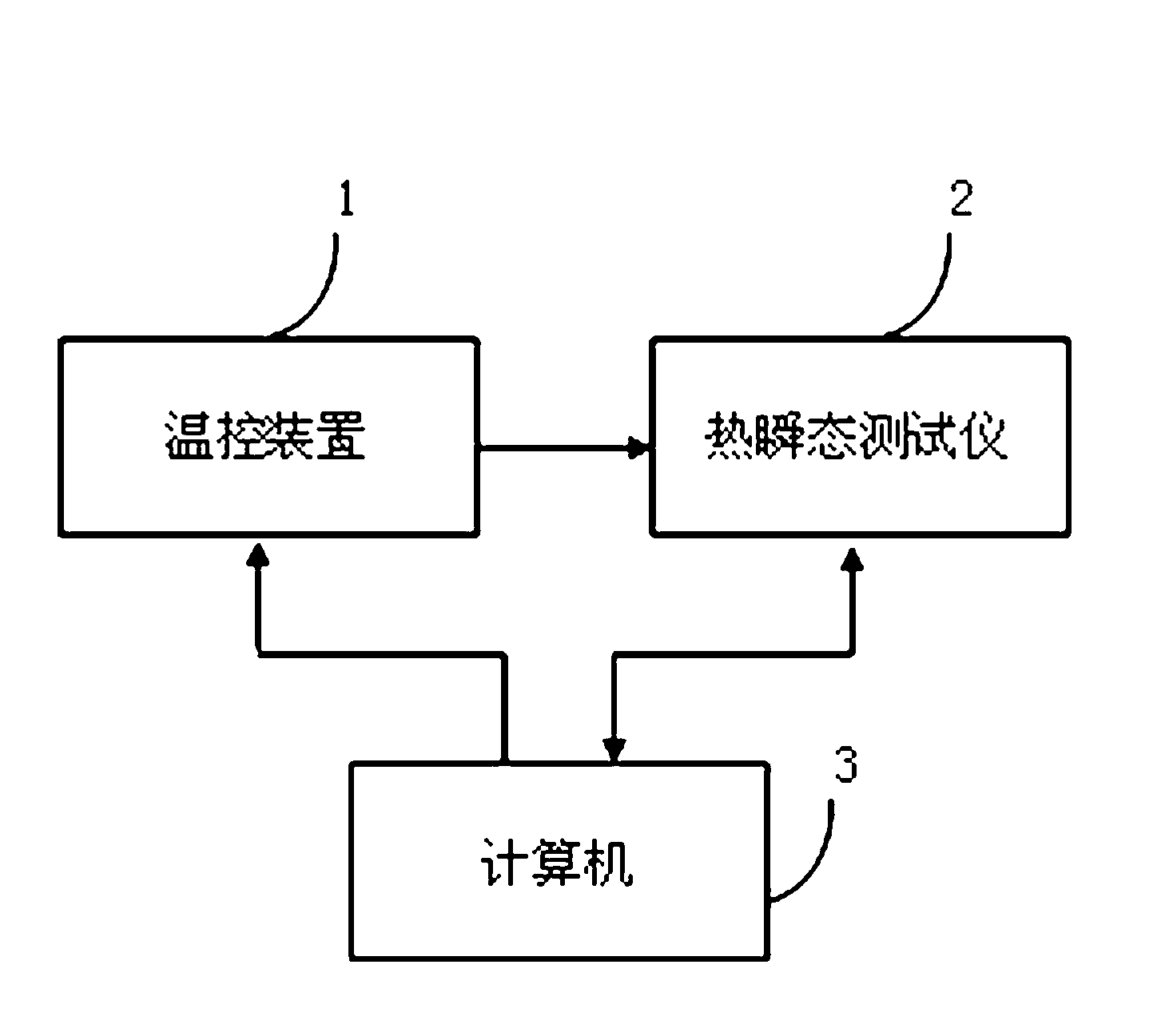

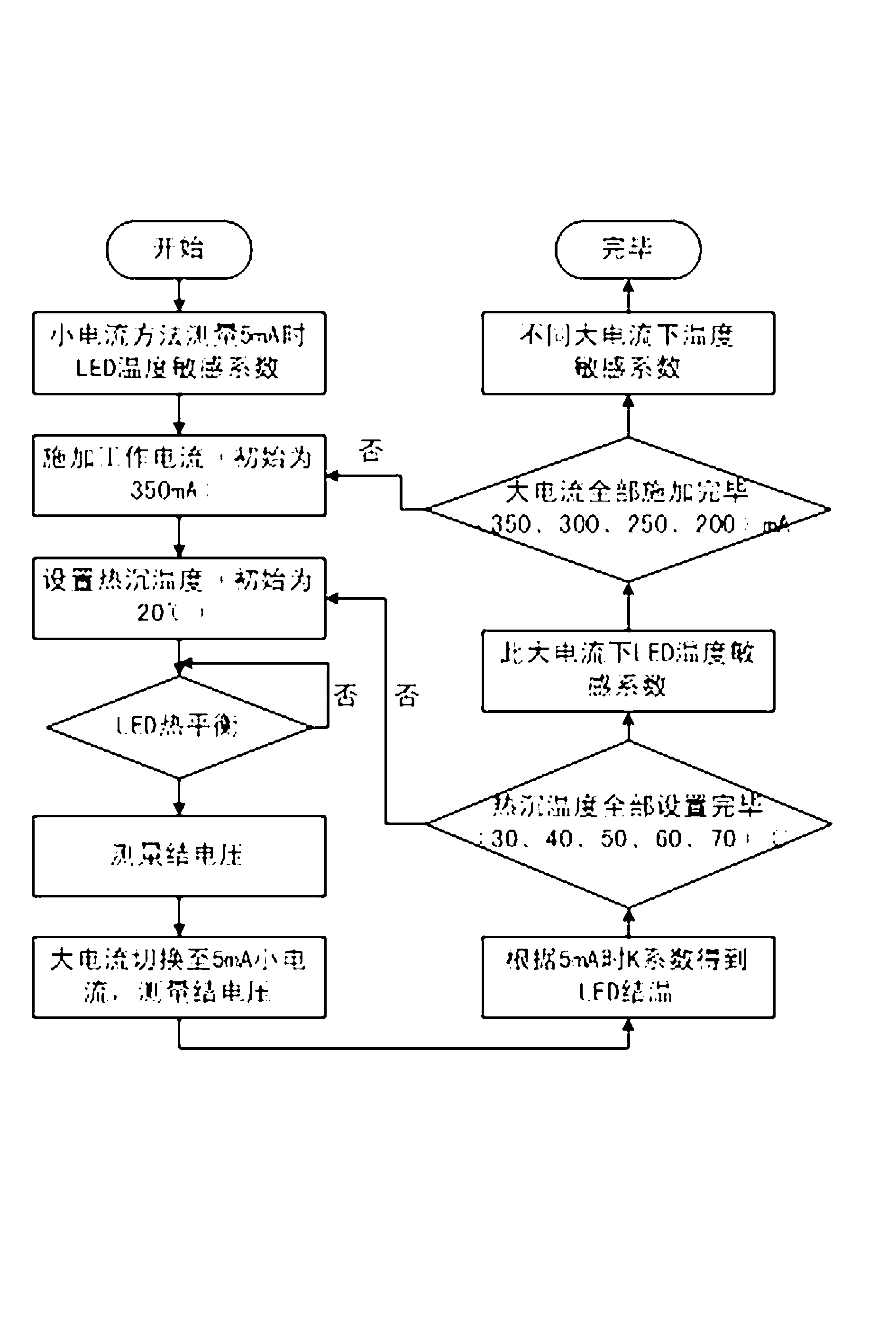

[0012] The non-contact high-power LED junction temperature testing method provided by the invention includes the measurement of K coefficient based on small current and the measurement of LED temperature sensitivity coefficient based on pulsed large current. Such as figure 1 As shown, the junction temperature measurement circuit includes a temperature control device 1 , a thermal transient tester 2 , and a personal computer 3 .

[0013] The temperature control device 1 is used to control the temperature of the heat sink in the thermal transient tester 2, the temperature control accuracy is ±0.1°C, and the temperature control range is 20°C~110°C. Thermal Transient Tester 2 is used to measure the thermal characteristics of LEDs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com