Light-emitting diode (LED) module based on high-voltage constant current technology

A LED module, high-voltage constant current technology, applied in the components of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve the problems of increased power supply costs, limited power transmission distance, poor uniformity of LED lights, etc. , to reduce maintenance difficulty, ensure waterproof and dustproof effect, and improve anti-attenuation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

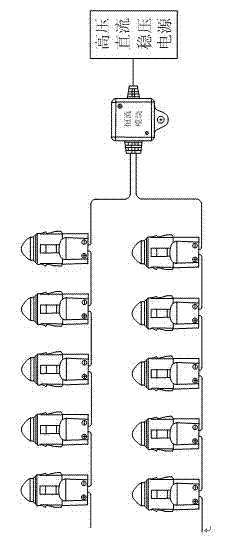

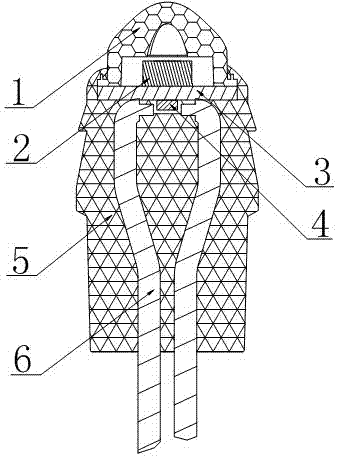

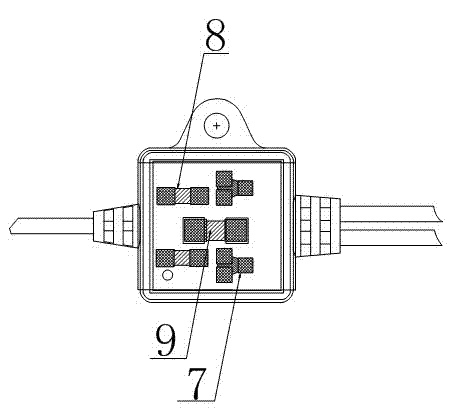

[0034] like figure 1 As shown, the LED module based on high-voltage constant-current technology mainly includes three parts: a high-voltage DC regulated power supply, a constant-current module, and a light-emitting LED lamp group. Among them, the high-voltage DC regulated power supply adopts 36V power supply, and in the LED industry, "high voltage" means that the voltage for powering LED lights is always higher than the LED tube voltage drop, that is, it is always greater than 5V, and the general high voltage is 12V and 24V. By configuring a 36V high-voltage power supply, it lays the foundation for realizing long-distance power supply and saving power consumption on the transmission line.

[0035] The constant current module is a major design in the present invention. Because the existing technology does not use constant current technology, the current on the light-emitting LED single lamp often fluctuates due to the influence of voltage attenuation, which makes it difficult ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com