Oil well reservoir fracture plugging agent, and preparation method and application thereof

A plugging agent and oil well technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as leakage, buried hill fracture reservoir damage, etc., to achieve safe use and good plugging effect , the effect of protecting oil and gas layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The components and weight ratio of the drilling lost circulation agent are: 14% of nylon 66, 15% of DSP-2, 34% of No. 90 asphalt, 14% of delayed expansion agent YH-14%, and 33% of calcium carbonate particles.

[0044] Wherein the components and weight ratio of nylon 66 are: 15-25mm nylon 6675%, 5-15mm nylon 6625%. The composition and weight ratio of No. 90 asphalt are: 50% of No. 90 asphalt of about 1mm, 25% of No. 90 asphalt of about 3mm, and 25% of No. 90 asphalt of about 6mm. The composition and weight ratio of the calcium carbonate particles are: 85% of the 200-mesh superfine calcium particles and 15% of the 3-4mm calcium carbonate particles.

[0045] When preparing, first add DSP-2 into water to fully dissolve to form a base slurry with a viscosity of 100-120S, and then mix it with other components in the formula evenly.

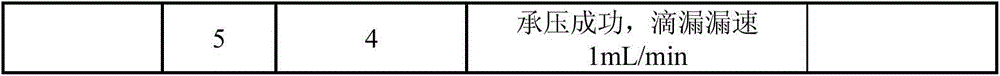

[0046] Aiming at the leakage in the completion process of buried hill wells, the plugging product prepared above was used for a pressure test, ...

Embodiment 2

[0053] Nanpu 23-P2006 is a development well in the buried hill reservoir of Nanpu No. 2 structure, and the main target interval is the Ordovician oil and gas layer in the buried hill. On April 26, 2011, when the well was drilled at a depth of 5235 meters, a lost circulation occurred in a fracture in a buried hill, and lost circulation occurred. The plugging slurry was prepared according to the following formula: nylon 6615%, DSP-210%, No. 90 bitumen 25%, delayed expansion agent YH-14%, calcium carbonate particles 35%, the balance is water.

[0054] Wherein the components and weight ratio of nylon 66 are: 15-25mm nylon 6660%, 5-15mm nylon 6640%. The composition and weight ratio of No. 90 asphalt are: 45% of No. 90 asphalt of about 1mm, 30% of No. 90 asphalt of about 3mm, and 25% of No. 90 asphalt of about 6mm. The composition and weight ratio of the calcium carbonate particles are: 75% of the 200-mesh superfine calcium particles and 25% of the 3-4mm calcium carbonate particles...

Embodiment 3

[0062] Well Gao 3102-9 is a planned well with three openings and five intervals on the Gao 96 platform. When the well was drilled to 3756 meters, a loss of return occurred suddenly; after 2 conventional plugging failed, the plugging was carried out according to the following formula: Nylon 6610 %, DSP-25%, No. 90 asphalt 25%, delayed expansion agent YH-15%, calcium carbonate particles 34%, and the balance is water.

[0063] The composition and weight ratio of the fiber material are: 15-25mm nylon 6670% and 5-15mm nylon 6630%. The composition and weight ratio of No. 90 asphalt are: 55% of No. 90 asphalt of about 1mm, 25% of No. 90 asphalt of about 3mm, and 20% of No. 90 asphalt of about 6mm. The composition and weight ratio of the calcium carbonate particles are: 65% of the 200-mesh superfine calcium particles and 35% of the 3-4mm calcium carbonate particles.

[0064] The prepared plugging slurry was pumped into the leaky layer, and the leak plugging was stopped when the drill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com