Methods for processing and preventing water scales in geothermal system

A technology of prevention method and treatment method, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc., can solve the problem of poor heat transfer performance, affecting heat transfer effect, and threats problems such as safe operation, to achieve the effect of increasing the product chain, simple process, and economical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

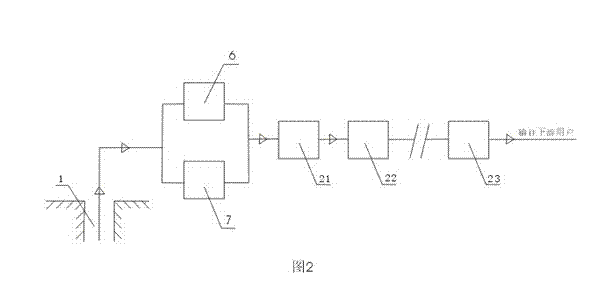

Image

Examples

Embodiment 2

[0038] Carry out according to embodiment one, but descaling agent is phosphoric acid and imidazoline mixture, all the other are the same as embodiment one.

Embodiment 3

[0040] Carry out according to embodiment one, but descaling agent is the mixture of hydrochloric acid, formaldehyde, aniline, all the other are the same as embodiment one.

Embodiment 4

[0042] Carry out according to Embodiment 1, but the geothermal system equipment is a geothermal power generation system, and its equipment includes storage tanks, flash evaporators, steam turbines, generator sets, compressors, pumps, etc., and the rest are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com