Anti-skidding and anti-abrasion production process of membrane

A production process and film technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of friction and slippage between the two roller shafts of the film, so as to reduce the defect rate and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

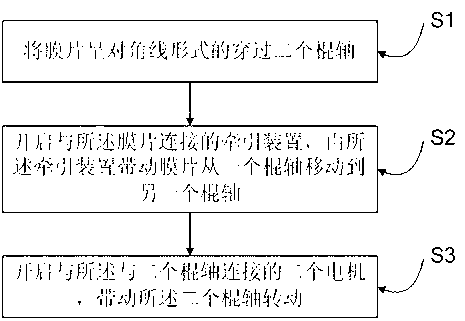

[0020] refer to figure 2 As shown, the general idea of the present invention is to provide a kind of anti-slip and anti-wear production process of diaphragm, comprising the following steps:

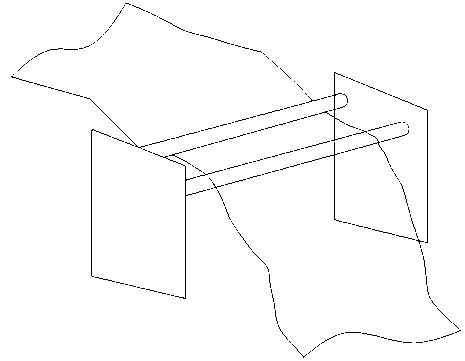

[0021] The first step is to pass the diaphragm diagonally through the two stick shafts;

[0022] The second step is to open the traction device connected with the diaphragm, and the traction device drives the diaphragm to move from one stick shaft to another stick shaft;

[0023] The third step is to turn on the two motors connected to the two stick shafts to drive the two stick shafts to rotate;

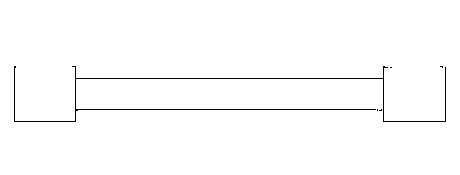

[0024] Among them, the two ends of the diaphragm are respectively in contact with the two ends of the two stick shafts, and the middle part of the diaphragm has a gap with the middle of the two stick shafts; and the two stick shafts connected The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com