Apparatus for film peeling and replantation

A technology of bonding film and peeling roller, applied in the direction of lamination device, pile separation, transportation and packaging, etc., can solve the problems of film waste, a lot of time protective film, etc., to reduce machine cost, prevent waste of protective film, reduce process effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

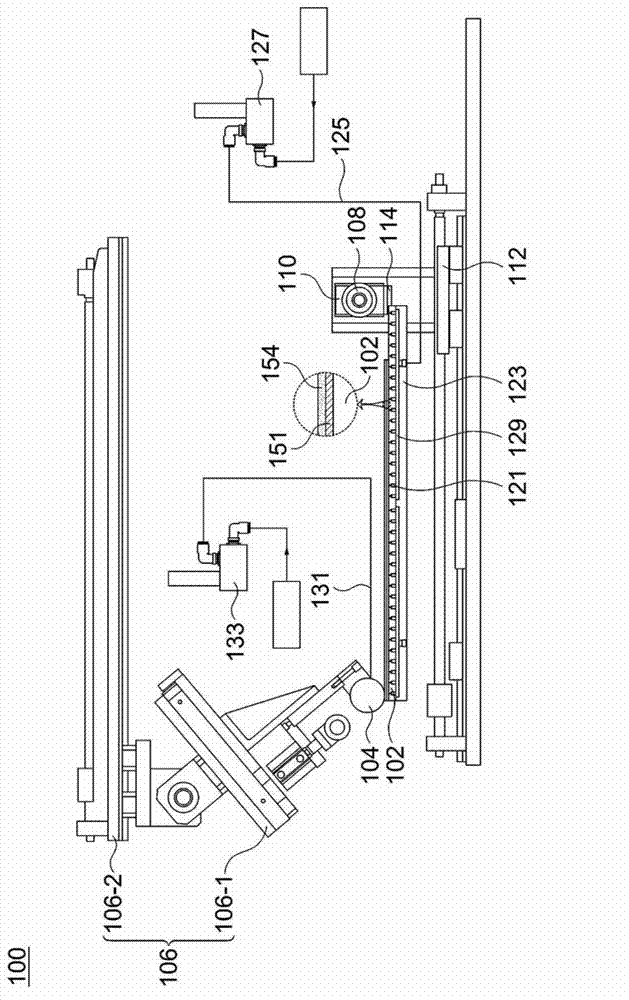

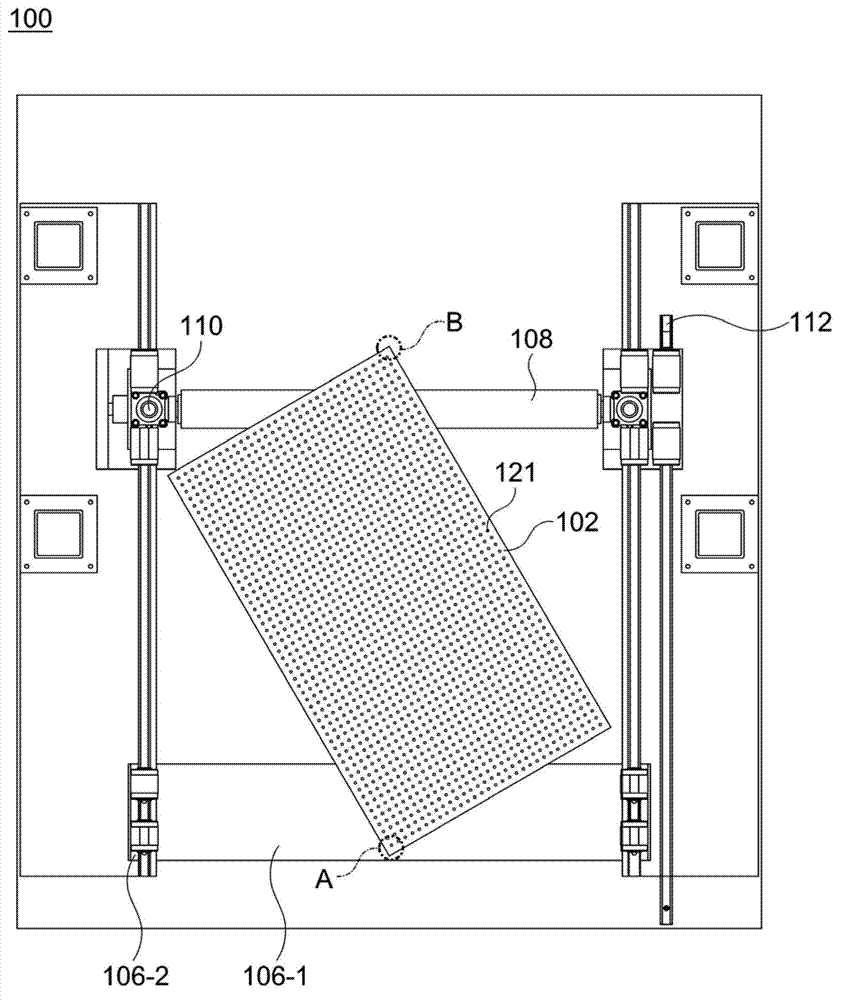

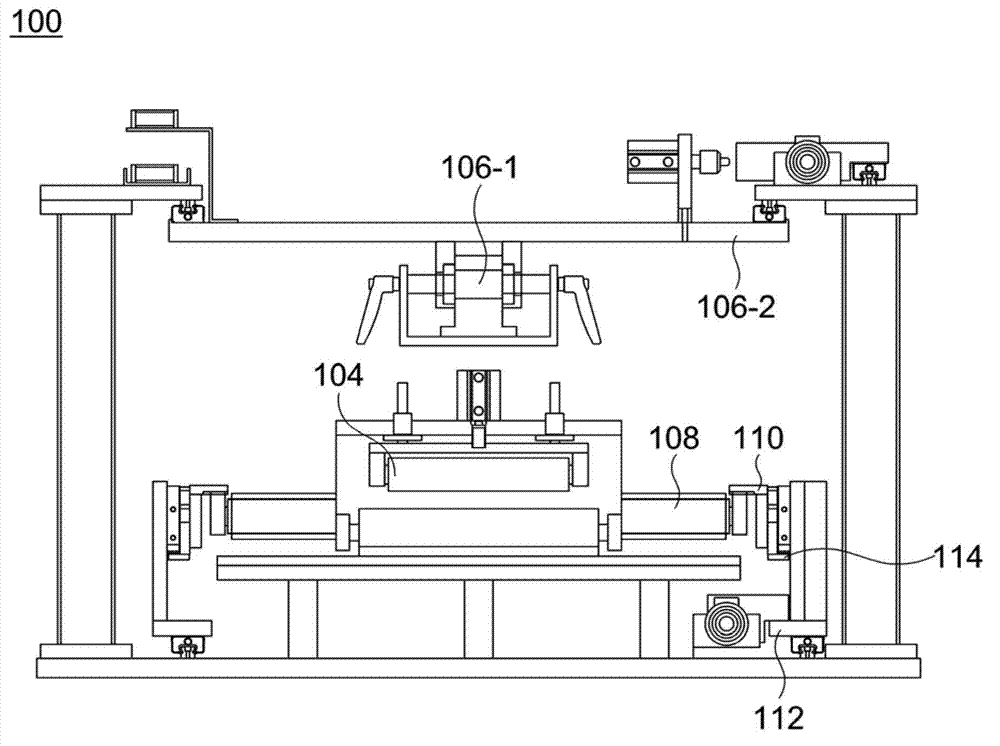

[0024] Below, will combine Figure 1 to Figure 9 Preferred embodiments of the present invention will be described. In the drawings, like reference numerals designate like or corresponding parts throughout the several views. In the embodiments of the present invention, detailed descriptions of well-known functions and constructions that are considered to unnecessarily obscure the gist of the present invention are omitted.

[0025] Until then, terms or words used in this specification and claims should not be construed as limited to one meaning, but should be understood based on the inventor's ability to define terms to describe his invention in the best way seen by others Appropriate concept.

[0026] However, those skilled in the art will appreciate that such embodiments are for illustrative purposes and not limitations of the claimed subject matter as disclosed in the specification and the appended claims. Therefore, it is obvious that those skilled in the art can make var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com