Five-layer medical liquid reagent packaging film and preparation method thereof

A technology for packaging film and liquid medicine, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of increasing the cost of medicine liquid packaging, low heat resistance of the film, and insufficient softness of the film, and achieve excellent optical performance, leakage and leakage. The effect of low bag rate and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

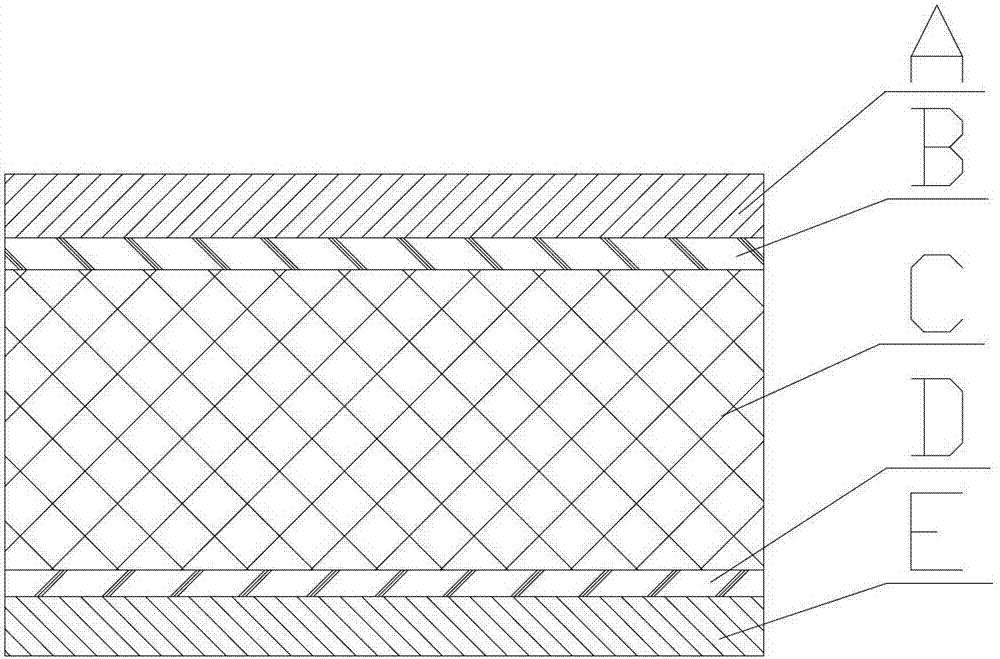

[0024] Such as figure 1 Shown is a schematic structural view of a five-layer medical liquid medicine packaging film in the present invention.

[0025] refer to figure 1 , a five-layer medical liquid pharmaceutical packaging film proposed by the present invention can be used to manufacture flexible packaging bags for packaging and using medicinal liquids. The medicinal liquids that can be packaged and used include: saline solution, glucose solution, cleaning solution, dialysate and Various other liquid medicines.

[0026] The film has a five-layer composite structure of an outer layer A, a sub-outer layer B, a core layer C, a sub-inner layer D and an inner layer E, wherein:

[0027] Outer layer A: its composition is homopolypropylene or high-density polyethylene, adding 0wt%-50wt% antioxidant, ethylene bisstearamide, poly-4-methylpentene, SEBS, calcium stearate , polyethylene and other processing aids or one or more materials in modified materials.

[0028] Sub-outer layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com