Large-scale glass steel wind power cabin cover bottom connecting base positioning tool

A technology for wind turbines and positioning tooling, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of line drawing deviation, increase repair, and easy to make mistakes, and achieve the effect of accurate positioning, easy installation and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

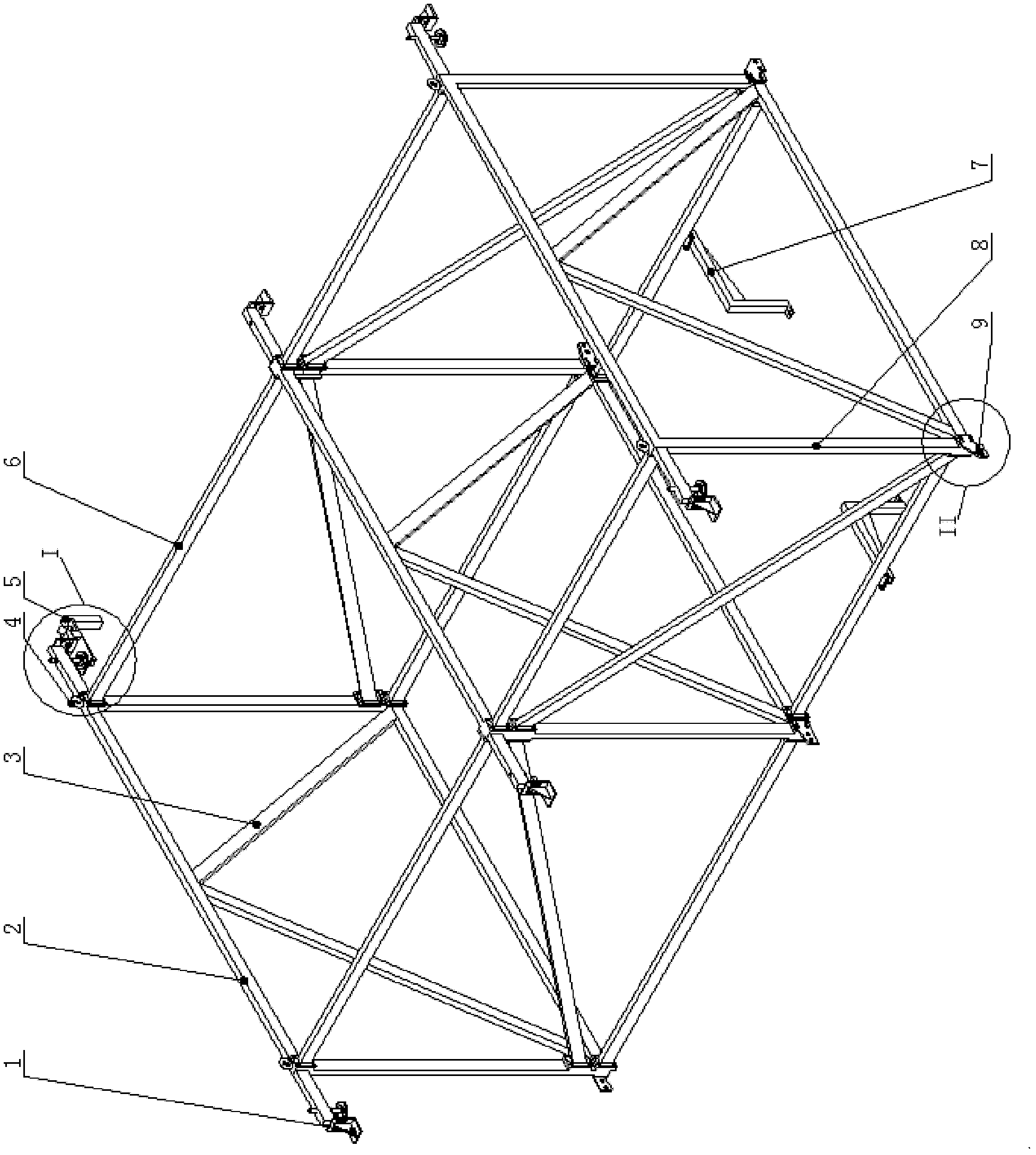

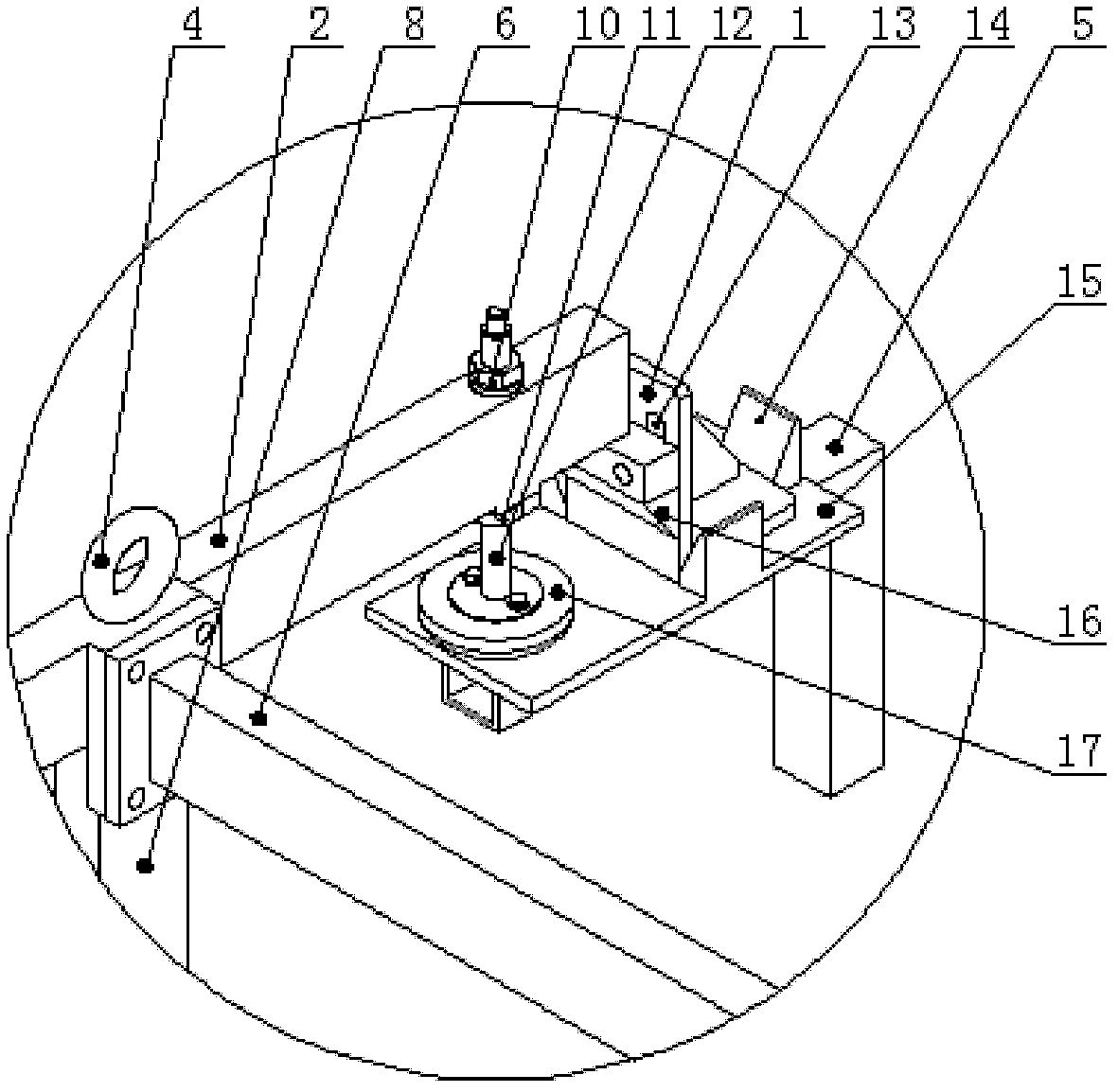

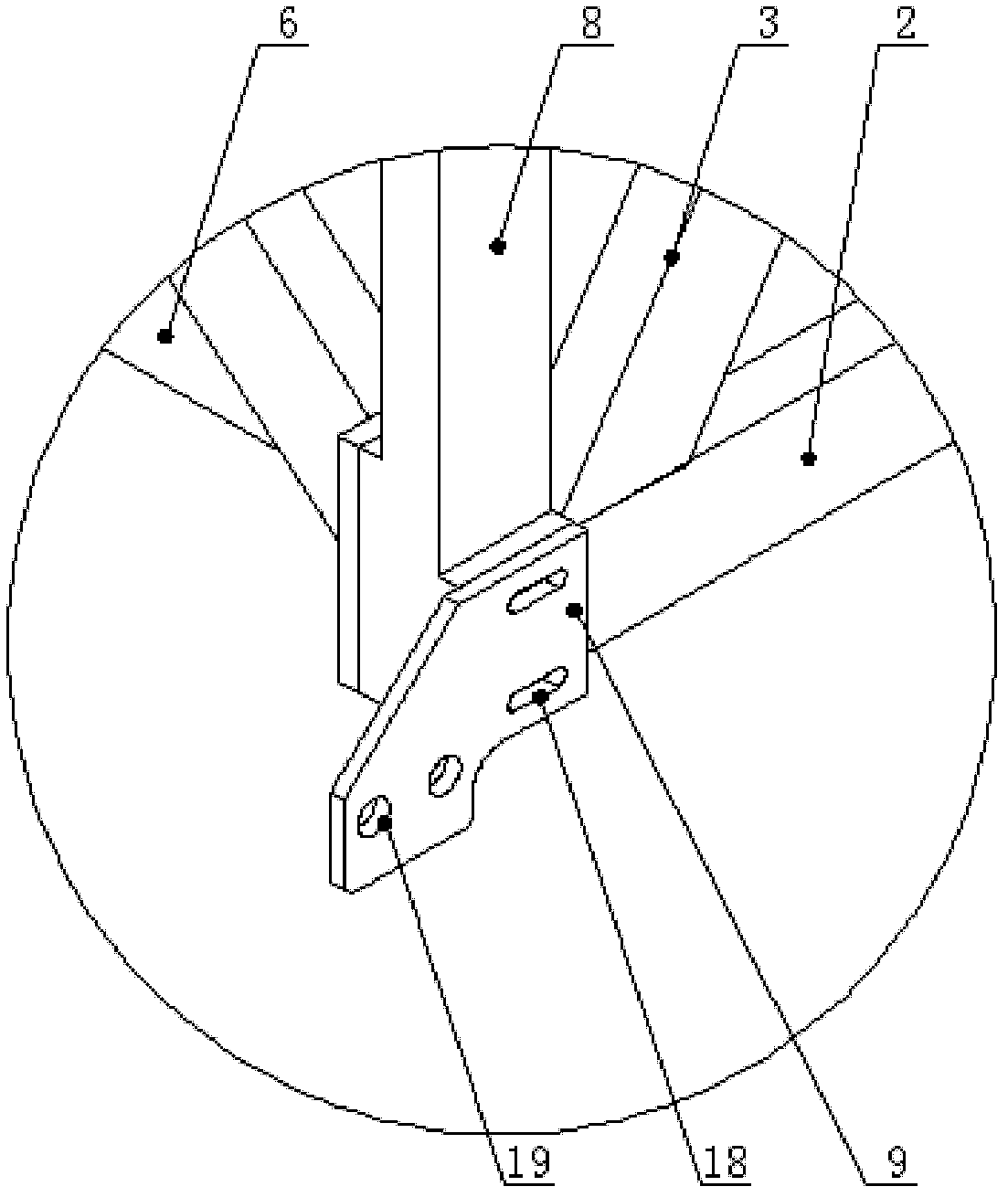

[0019] A positioning tool for the connecting seat at the bottom of the nacelle cover of a large FRP wind turbine, such as Figure 1~5 As shown, the innovation of the present invention is: comprise square frame, all install the mounting plate 9 facing the outside of the frame at the middle part and the four corners of the bottom two sides of the frame, at the middle part and the four corners of the upper end two sides of the frame Install the positioning seat facing down vertically ( figure 1 In part I), two spacers 7 are symmetrically installed on both sides of the bottom of the frame. Diagonal stiffeners 3 are installed inside the frame and on the four sides, and four hoisting rings 4 are installed on the upper end of the frame.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com