Cone piercing mill for producing seamless tubes

A technology of seamless tubes and inclined cones, which is used in manufacturing tools, metal rolling stands, metal rolling mill stands, etc., can solve the problem of not being able to replace the rolls at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

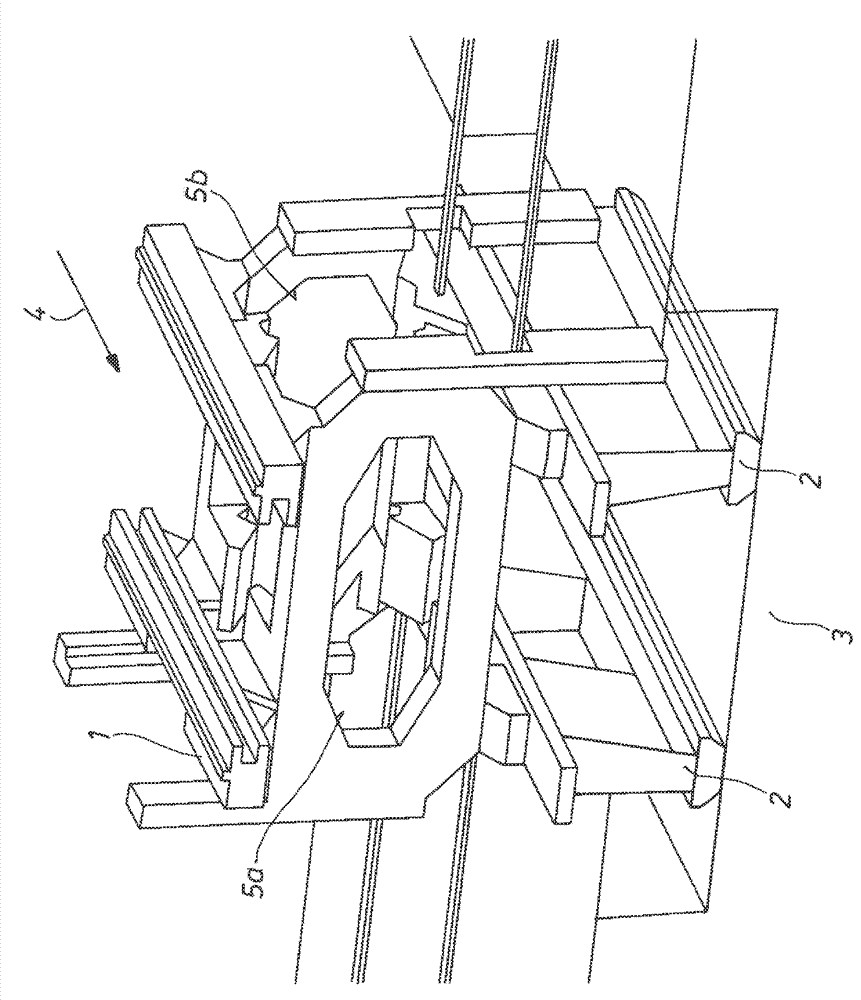

[0033] exist figure 1 The rolling mill stand 1 shown in figure 2 and image 3 ). Mounting windows 5 a , b for the tapered rolls 6 a , b inserted therein from each stand side are formed in both the left and the right side of the stand with respect to the rolling axis or rolling center 4 .

[0034] Schematic figure 2 From the rolling stock exit side, the rolling stand 1 converted into a skewed cone rolling mill 7 is shown here and two conical rolls supported in the mounting part 8 and pointing forward with their drive coupling 9 in the plane of the drawing can be seen 6 a , 6 b are arranged horizontally next to each other in the shown operating position, that is to say symmetrical to the rolling axis or rolling center 4 at a larger divergence angle, that is to say divergent towards the rolling stock exit side. To the right and left of the rolling axis 4 , doorframe-like guide frames 10 a , 10 b are placed on the rolling stand 1 . Each guide frame 10a, 10b accommodates a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com