Improved heating element for a cooking apparatus

A technology for heating elements and cooking equipment, applied in electrical elements, fluid heaters, ohmic resistance heating, etc., can solve problems such as high cost, achieve the effect of easy manufacturing and avoid complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

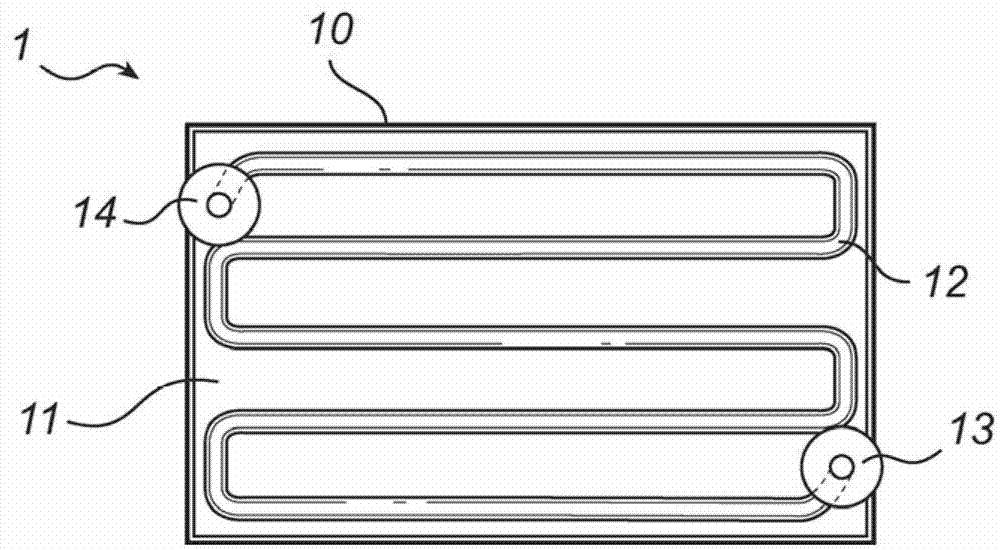

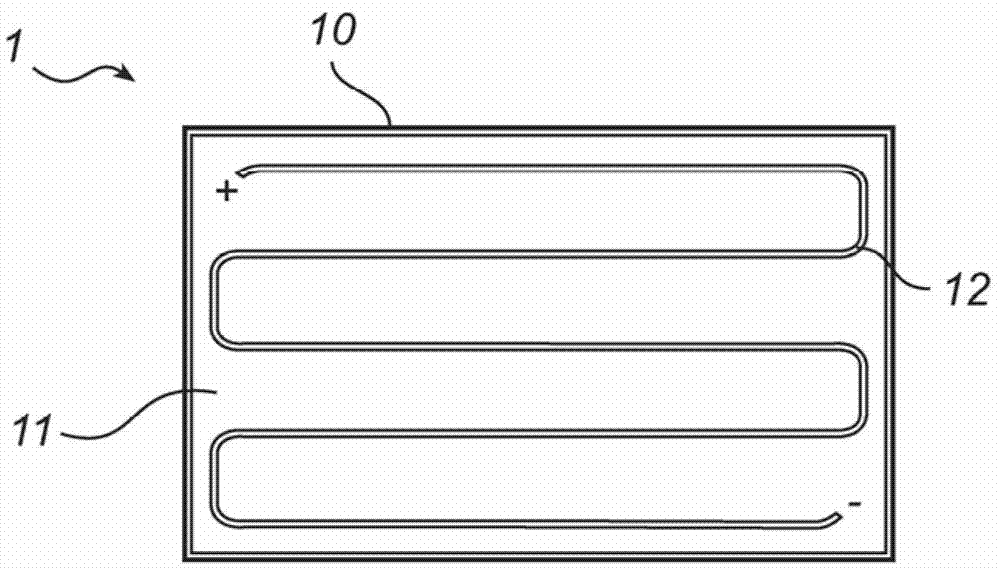

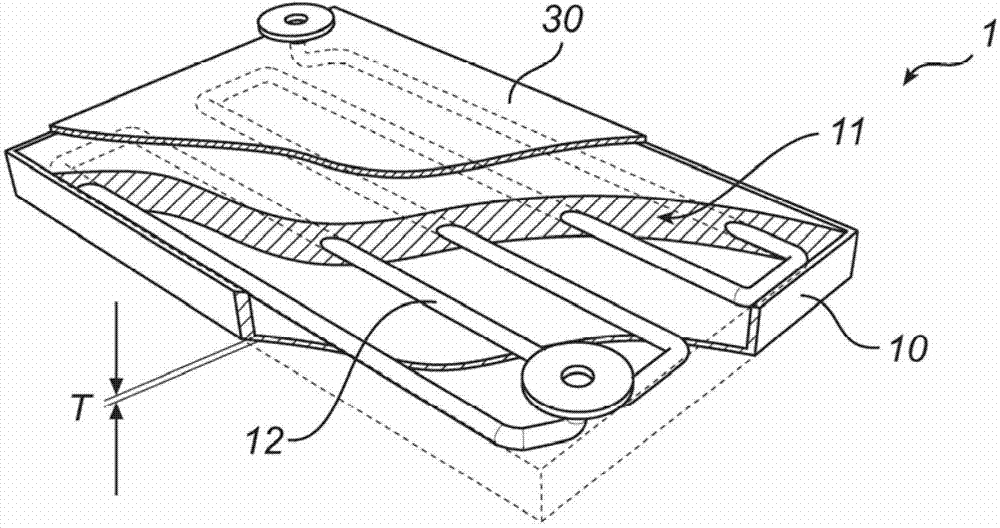

[0044] Heating elements for cooking appliances 1 in figure 1 and figure 2 above is displayed. The heating element 1 is composed of a housing 10 and a heating body 11 . The housing 10 is composed of a cooking side (not shown) and side surfaces extending from the cooking side to form the housing.

[0045] In one embodiment, the heating element 1 is a heating plate.

[0046] Housing 10 is made of corrosion resistant steel. Corrosion-resistant steel, a commonly used heating element material, has improved resistance to cooking fluids such as salt-containing grease compared to aluminium. With other commonly used materials, these fluids easily damage the exposed parts of the heating element 1, resulting in a rough surface. Consequently, heat transfer, and thus cooking of the finished food product, becomes more uneven and more difficult to control.

[0047] Additionally, corrosion-resistant steel has improved resistance to the chemicals used to clean heating elements, such as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com