Finger protection for 90 deg header

A technology for finger protection and protection of components, which is applied to the components of connection devices, the assembly/disassembly of contacts, and devices to prevent wrong connection, etc., to achieve the effect of improving user-friendliness, maintaining length, and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

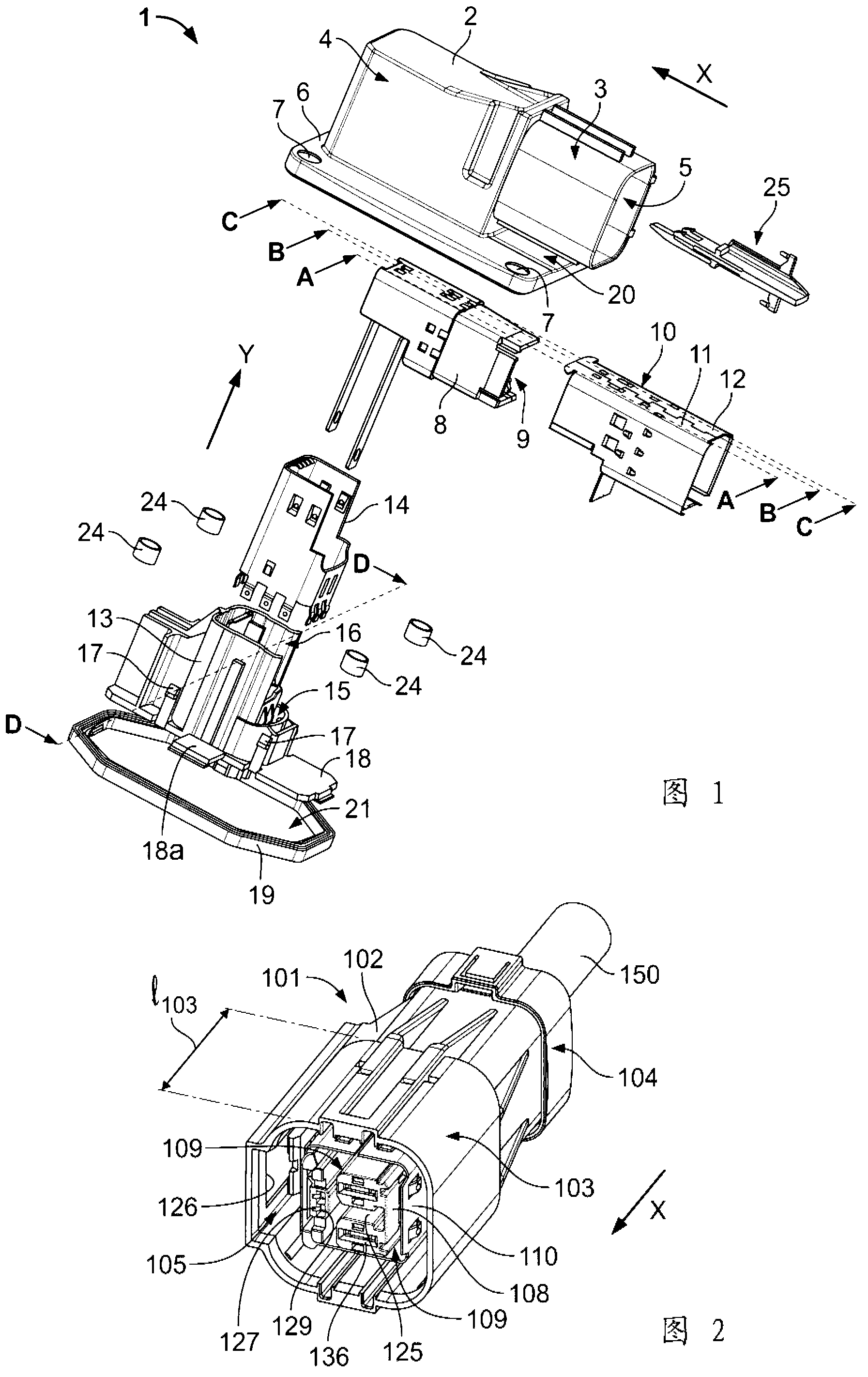

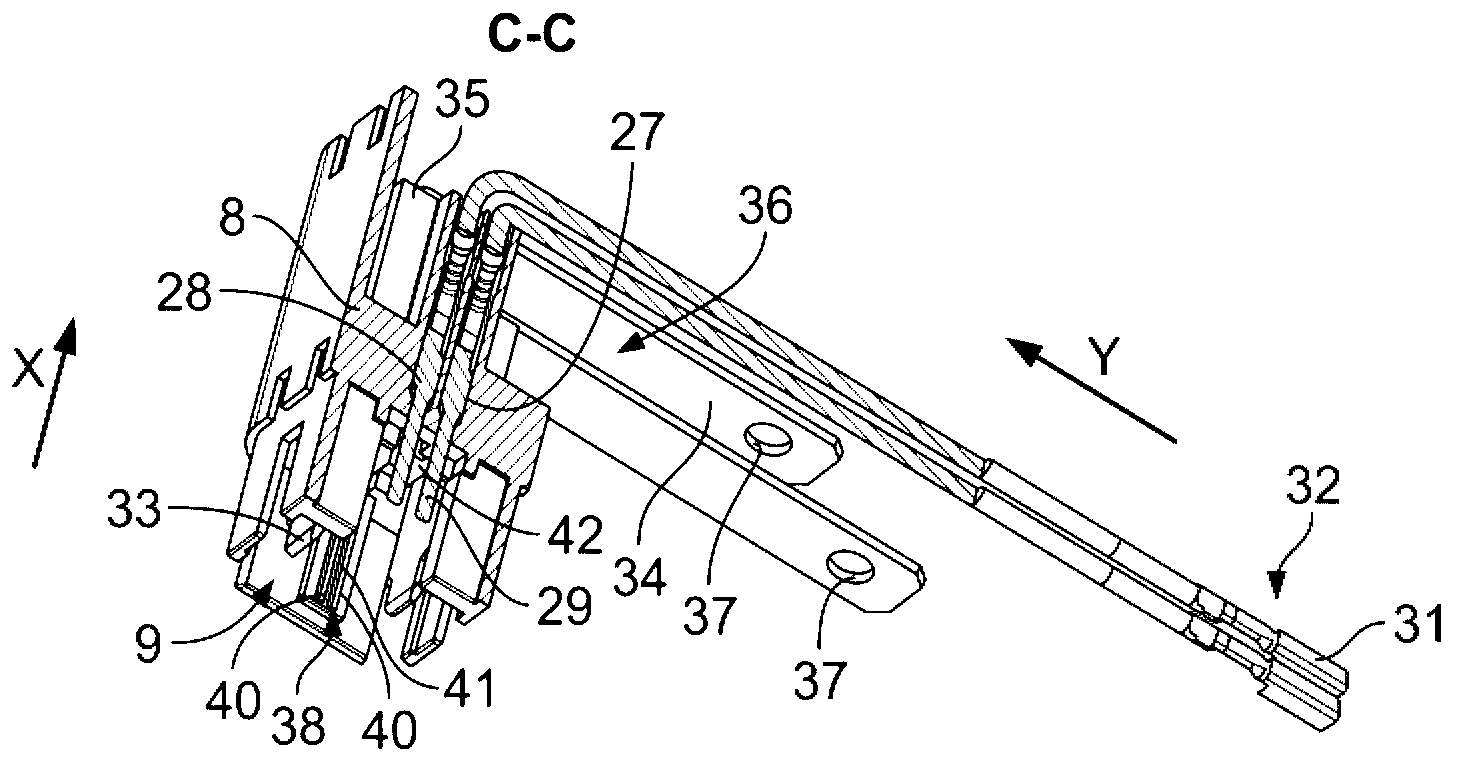

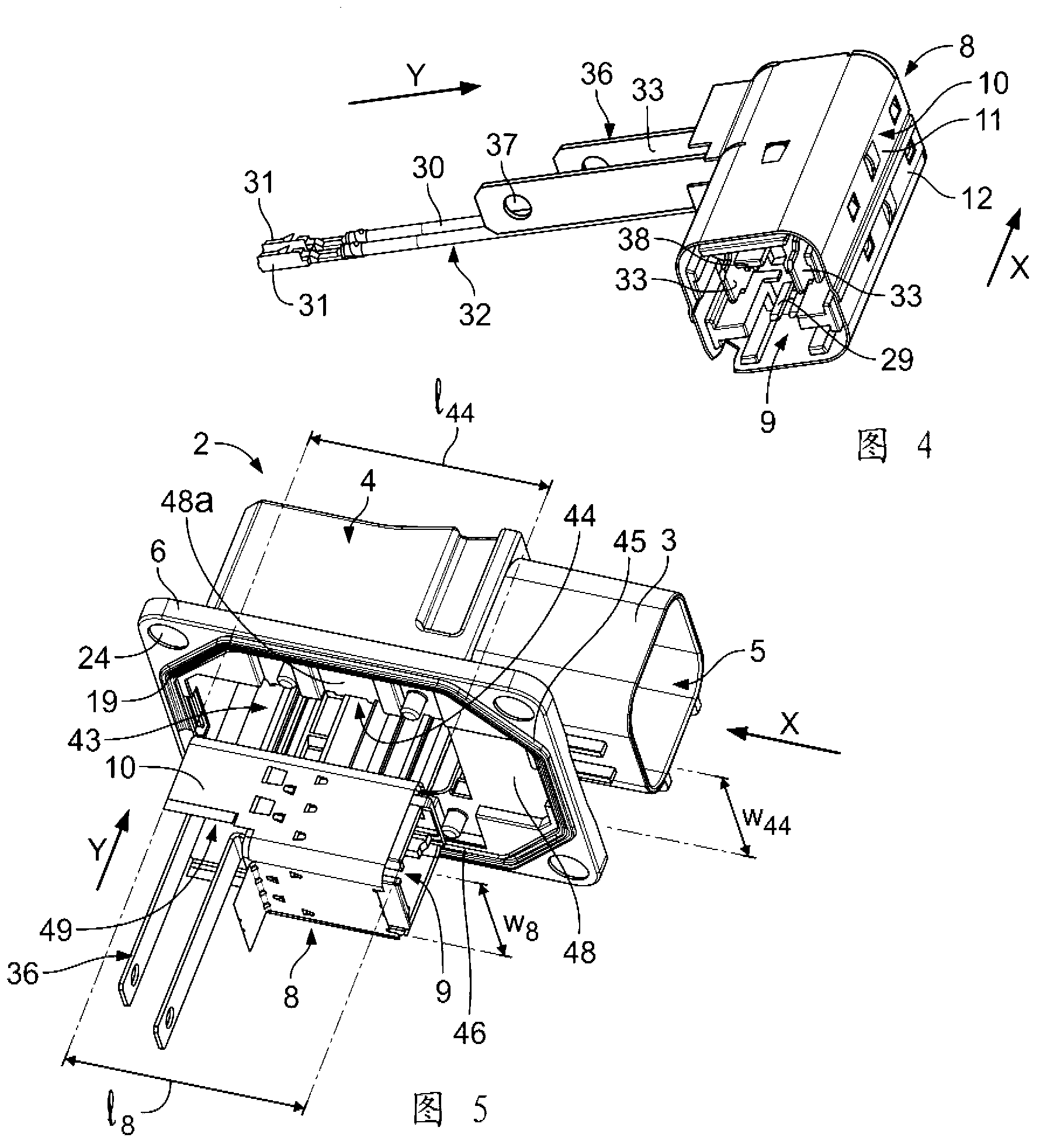

[0065] First, refer to figure 1 Description plug-in electrical connector 1, figure 1 The plug-in connector 1 is shown in an exploded perspective view. The plug-in connector 1 includes an outer body 2 having a plug part 3 and a mounting part 4. The plug part 3 has a plug opening 5 which opens in the plug-in direction X of the plug-in connector 1. The mounting portion 4 is used to mount the plug-in connector 1 to an electrical device, and is therefore provided with a base 6 having a mounting support 7 in the form of a through hole. The installation opening (not shown) of the outer body 2 and the installation support portion 7 are opened to the installation direction Y extending perpendicular to the insertion direction X.

[0066] The plug terminal housing 8 of the plug connector 1 has a plug surface 9. The insertion surface 9 of the plug terminal housing is open in the insertion direction X. The plug terminal housing 8 is arranged under the outer body 2 so as to be inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com