Optical microphone

A microphone and optical technology, used in optical signal detection transducers, measuring devices, instruments, etc., can solve the problem of measuring devices becoming larger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

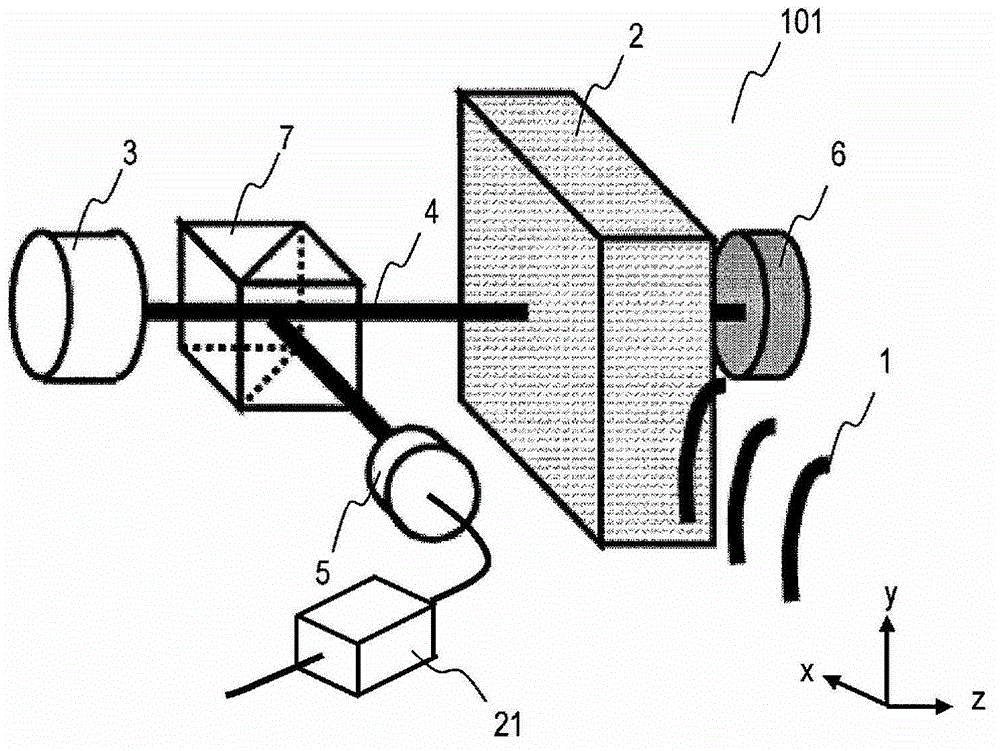

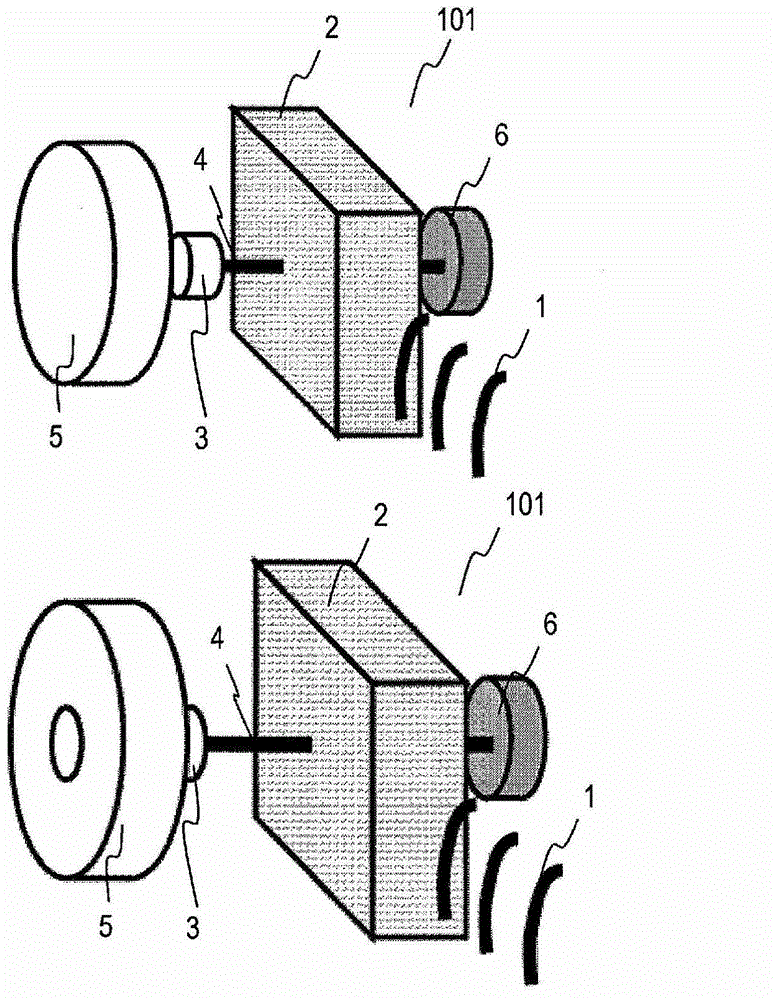

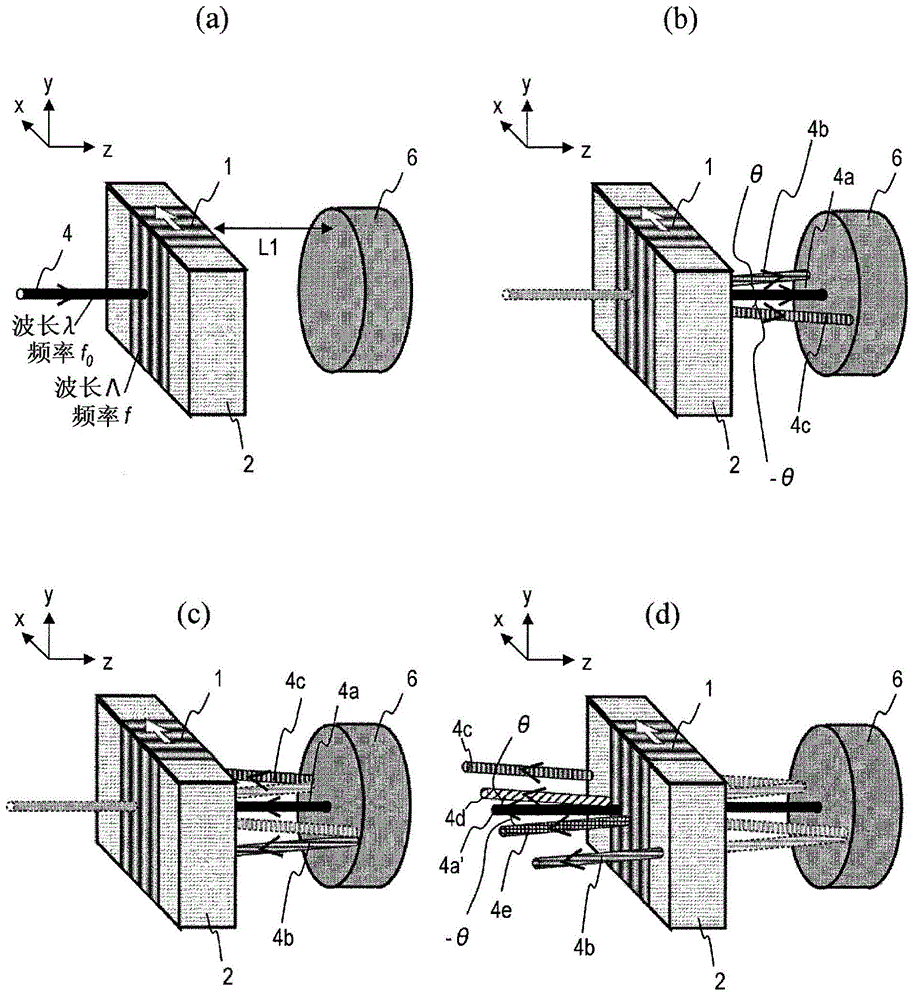

[0165] Hereinafter, a second embodiment of the optical microphone according to the present invention will be described with reference to the drawings. In the optical microphone of Patent Document 1 or the method of Patent Document 2, although sound waves can be detected, the propagation direction of the sound waves cannot be determined, and the sound waves cannot be separated and detected according to frequencies. In contrast, the optical microphone of this embodiment can realize at least one of determining the propagation direction of the sound wave and separating and detecting the sound wave according to the frequency of the sound wave.

[0166] According to the optical microphone of this embodiment, at least one of the first interference light wave and the second interference light wave is detected using a photoelectric conversion element array including a plurality of photoelectric conversion elements. Therefore, the azimuths of these interfering light waves with respect t...

no. 3 approach

[0256] Figure 24 The structure of the main part of the optical microphone 103 of this embodiment is shown. The optical microphone 103 separates and detects the sound wave 1 according to its frequency using the light wave 4 . Therefore, the optical microphone 103 has the propagation medium section 2 , the light source 3 , the photoelectric conversion element array 26B, the reflection section 6 , the beam splitter 7 , and the light receiving lens system 15 . The configuration other than the photoelectric conversion element array 26B is the same as that of the optical microphone 102 of the second embodiment.

[0257] The photoelectric conversion element array 26B includes a plurality of photoelectric conversion elements 15 a , 15 b . . . 15 h. Each photoelectric conversion element has a plurality of ring-shaped light-receiving portions with different inner diameters and outer diameters, and the light-receiving portions are concentrically arranged around the position where the ...

no. 4 Embodiment approach

[0275] Figure 26 (a) shows the structure of the main part of the optical microphone 104 of this embodiment. The optical microphone 104 determines the propagation direction of the sound wave 1 using the light wave 4 , and separates and detects the sound wave 1 according to the frequency. To this end, the optical microphone 103 has a propagation medium section 2 , a light source 3 , a photoelectric conversion element array 26D, a reflection section 6 , a beam splitter 7 , and a light receiving lens system 15 . The configuration other than the photoelectric conversion element array 26D is the same as that of the optical microphone 102 of the first embodiment.

[0276] The photoelectric conversion element array 26D includes a plurality of photoelectric conversion elements 5a1, 5a2, ... 5a8, 5b1, 5b2, ... 5b8, ... 5x1, 5x2, ... 5x8. Each photoelectric conversion element has a partially ring-shaped light receiving portion, and the light receiving portion is two-dimensionally arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com