Tensioning device comprising at least two ventilation elements

A technology of tensioning device and ventilation element, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., to achieve the effect of length increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

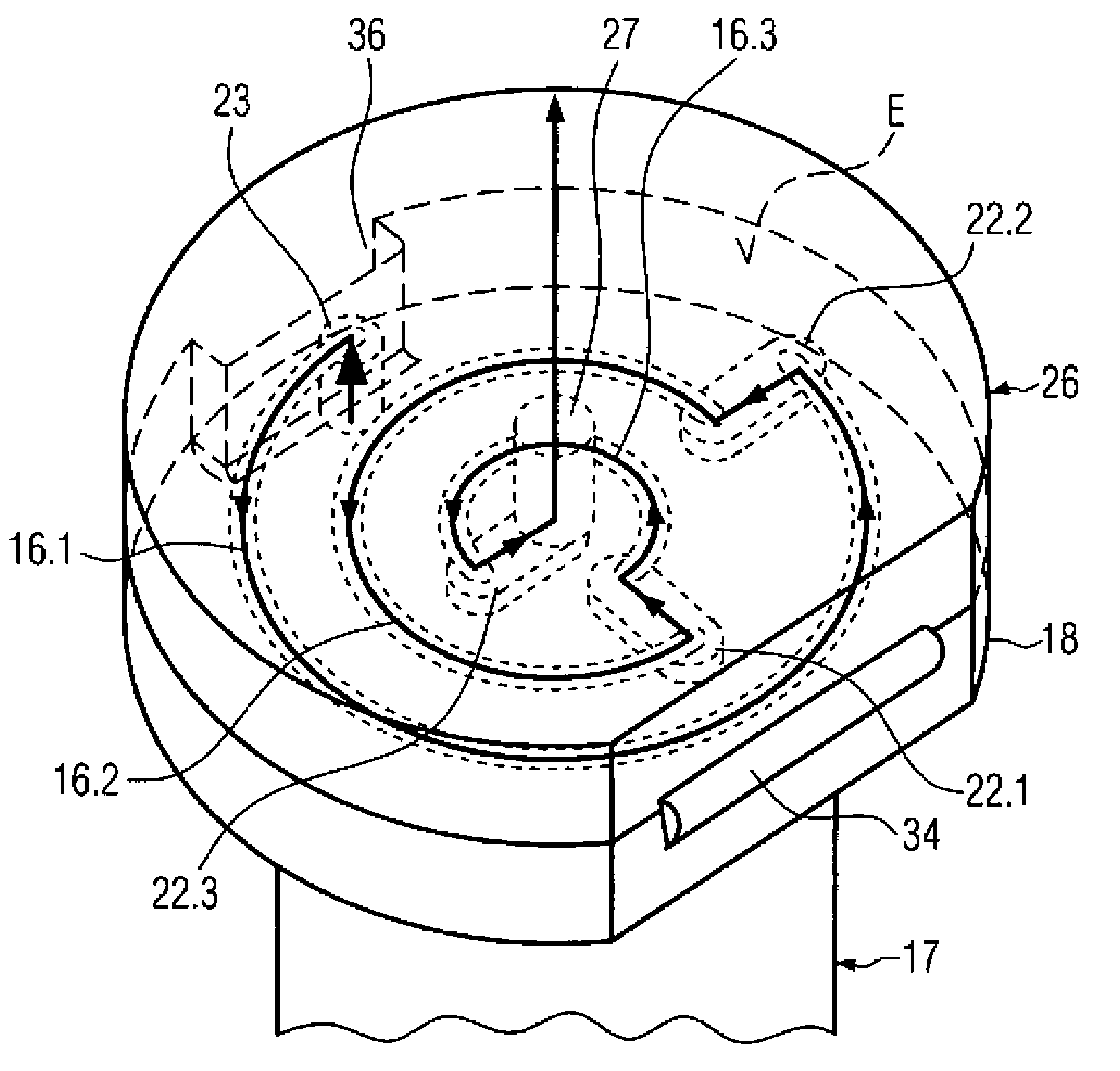

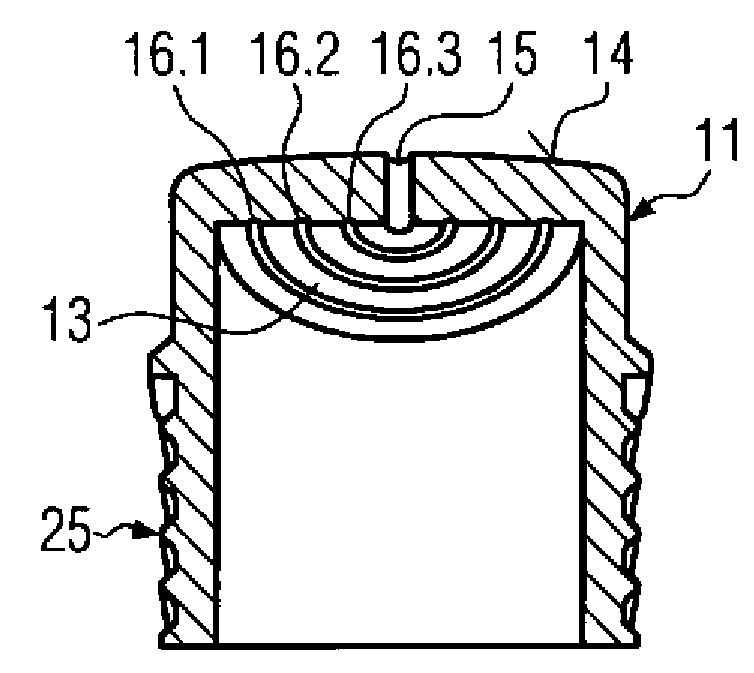

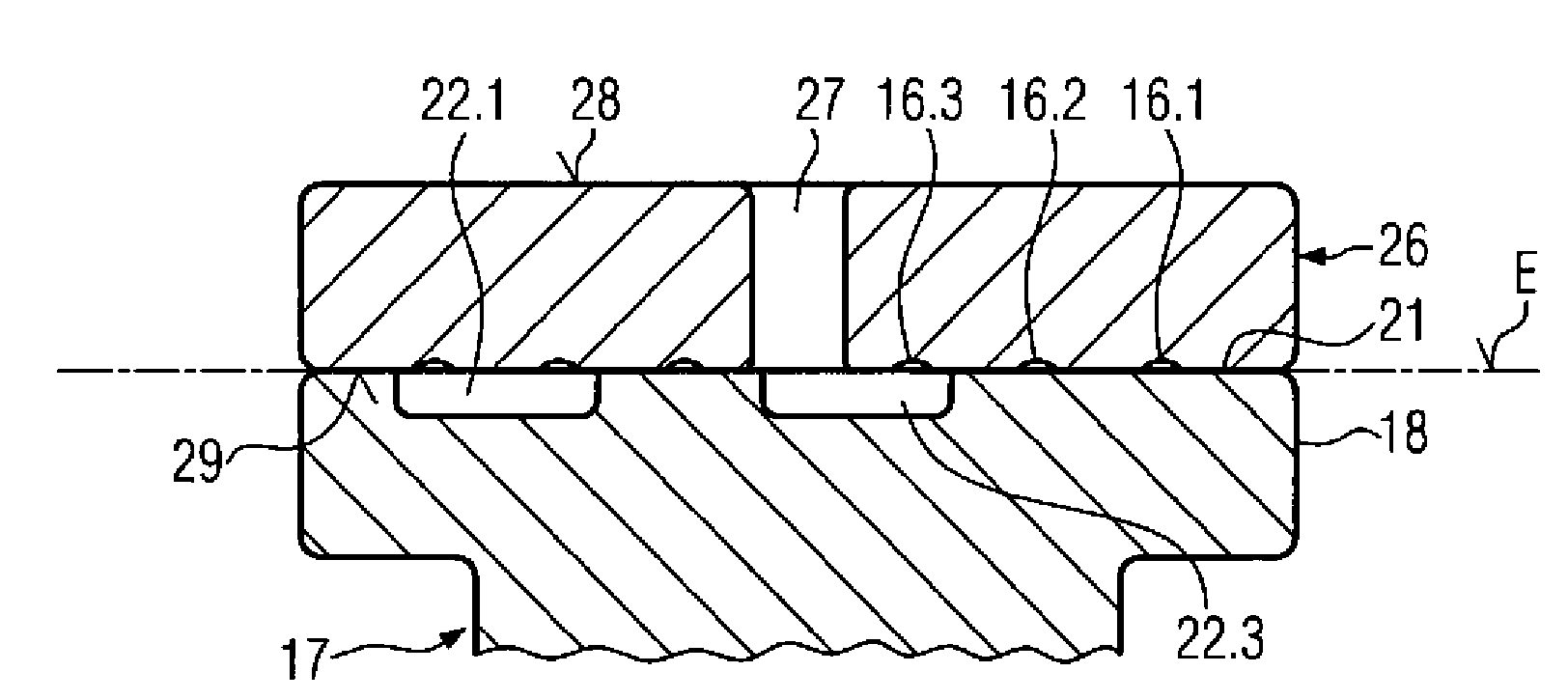

[0041] A control chain drive system 1 of an internal combustion engine is schematically shown in FIG. 1 . The control chain drive system 1 basically comprises a crankshaft sprocket 2, two upper camshaft sprockets 3 and 4, a control chain 5 wound around these sprockets, a slide rail 6, a pivotably arranged tensioning rail 7 and Tensioner 8 (or chain tensioner). For example, a screw-in chain tensioner 8 is shown, which is screwed into the region of the engine block housing 9 . The tensioning device 8 comprises a housing 10 and a tensioning piston 11 guided longitudinally displaceably in the housing 10 . The tensioning device 8 is coupled to the engine oil hydraulic transmission system, so that the hydraulic oil flows into the interior of the tensioner housing 10 through a feed hole (not shown) and acts on the tensioning piston 11 with pressure so that it presses against The tensioning rail 7 is pivotably arranged so that it bears against the control chain 5 under pretension. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com