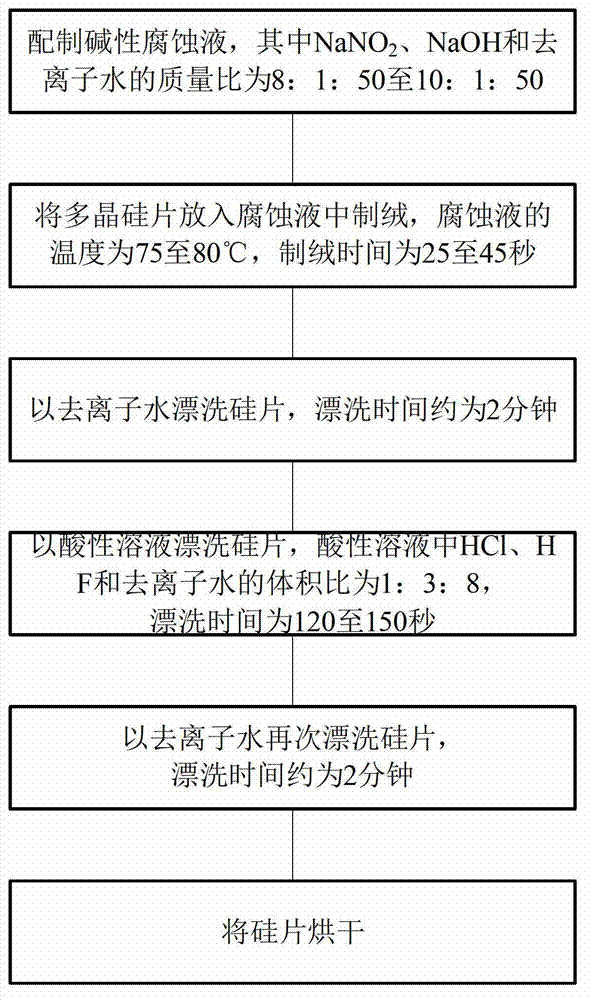

Polycrystalline silicon alkaline texturing method

A polysilicon and alkaline technology, applied in the field of solar cells, can solve the problems of cell efficiency and appearance defects, inability to match the anti-reflection film process, and inability to obtain a good suede surface, etc., to achieve high production costs, reduce reflectivity, and avoid chromatic aberration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

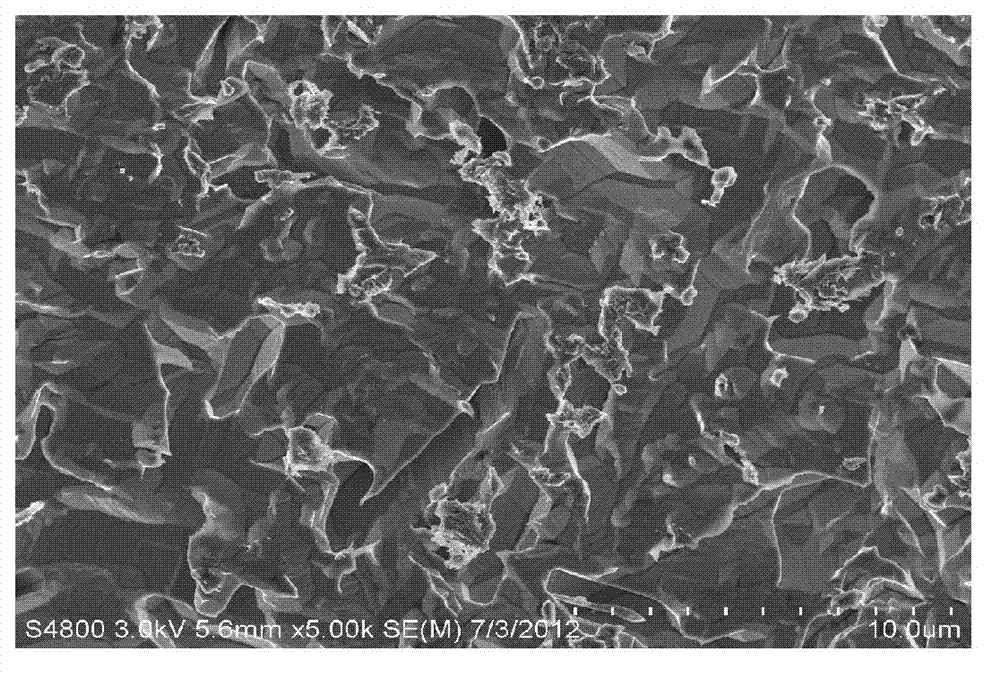

[0018] Prepare NaNO 2 , NaOH and deionized water mass ratio of 8:1:50 alkaline corrosion solution. Put the chemically purified polysilicon wafer (area 156mm×156mm) into the above-mentioned etching solution at 75°C. After 30 seconds of texturing, the silicon wafer was taken out and rinsed with deionized water for 2 minutes. Then put the silicon wafer into the acidic solution with a volume ratio of HCl, HF and deionized water of 1:3:8, and rinse for 120 seconds. Then rinse with deionized water for 2 minutes and dry. like figure 2 The scanning electron microscope (SEM) photo of the surface of the silicon wafer after the texturing treatment provided by the present invention shows that the textured surface is composed of irregular corrosion pits composed of flat surfaces similar to cut surfaces, which are uneven and have an obvious textured feeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com