Quartz watch movement

A watch and movement technology, applied to clocks and watches, gear mechanisms, electric mechanical clocks, etc., can solve the problems of increased watch material costs, deformation of the upper and lower shafts of the over-wheel shaft, and reduced reliability of the movement time of the movement, so as to achieve normal punctuality Efficient operation, avoiding wear and improving reliability

Active Publication Date: 2014-10-22

吴中一

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] 2) In the above-mentioned first stop-second clutch mechanism, whenever the hour and minute are adjusted, the passing wheel will be inclined due to the displacement of the clutch lever. After the adjustment is completed, the meshing with the second wheel and the minute wheel will be resumed. This is the case for a long time, and the frequent inclination The action will cause the upper and lower tenons of the wheel shaft to deform, thereby reducing the reliability of the movement time

[0015] 3) In the above-mentioned second stop-seconds clutch mechanism, a setting intermediate wheel component is arranged between the setting wheel and the span wheel, thus resulting in an increase in the material cost of the watch

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

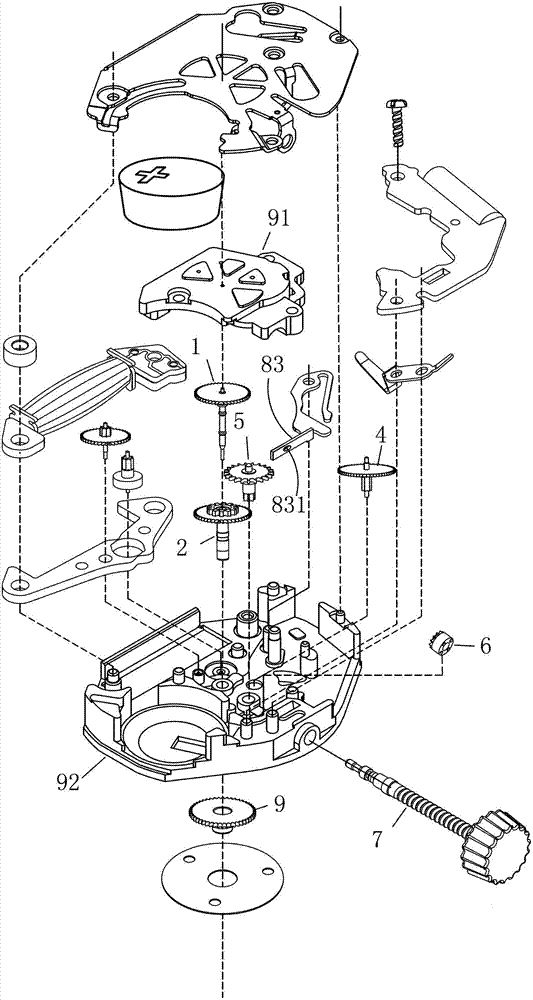

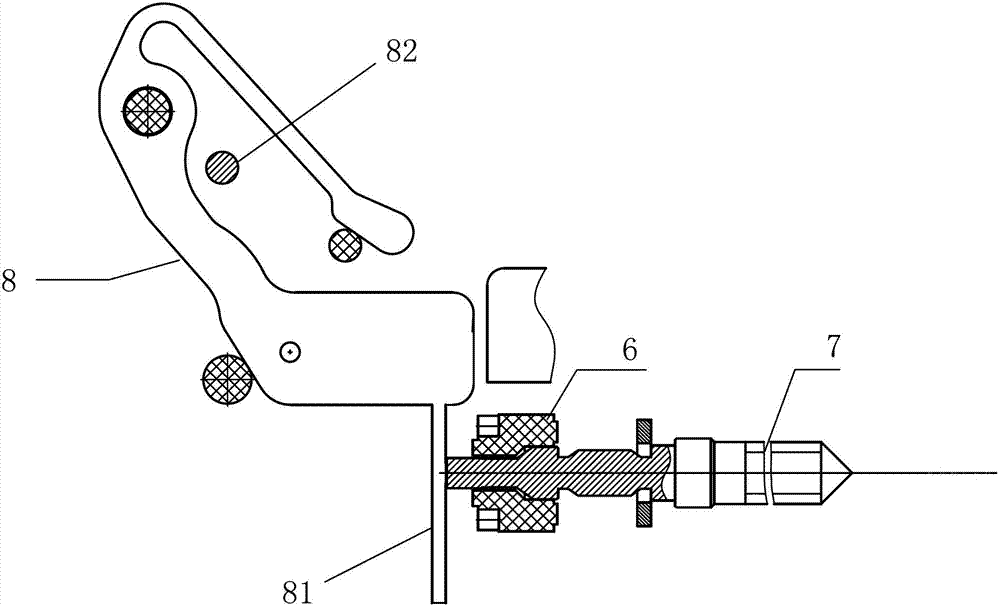

The invention discloses a quartz watch clock mechanism provided with no clutch lever and capable of improving the travel time reliability of the clock mechanism. A minute wheel is connected with a needle shifting wheel in a transmission way through a back gear, a lower pivot of a third wheel shaft passes through a space in which an original clutch lever is canceled to be arranged in a corresponding shaft hole on a main clamping plate, a connection structure which enables the third wheel shaft to be always engaged with the minute wheel blade and to rotate elastically relatively at a static state when a handle shaft is pulled outwards and a minute hand is adjusted through the needle shifting wheel, the back gear and the minute wheel shaft is also arranged between a minute wheel tube and the minute wheel blade, and a second stop rod which can be connected or disconnected with a second stop electrode is also arranged in front of the handle shaft. The clutch lever part is omitted, so that a second wheel, the third wheel and the minute wheel always stay at a precise engagement state, and the time travel reliability of the clock mechanism can be improved; and meanwhile, the elastic connection structure which can rotate relatively is arranged between the minute wheel tube and the minute wheel blade, so that precision in time travel still can be guaranteed, and a function for high efficiently correcting the hour and the minute can be realized under the situation that the needle shifting intermediate wheel is omitted.

Description

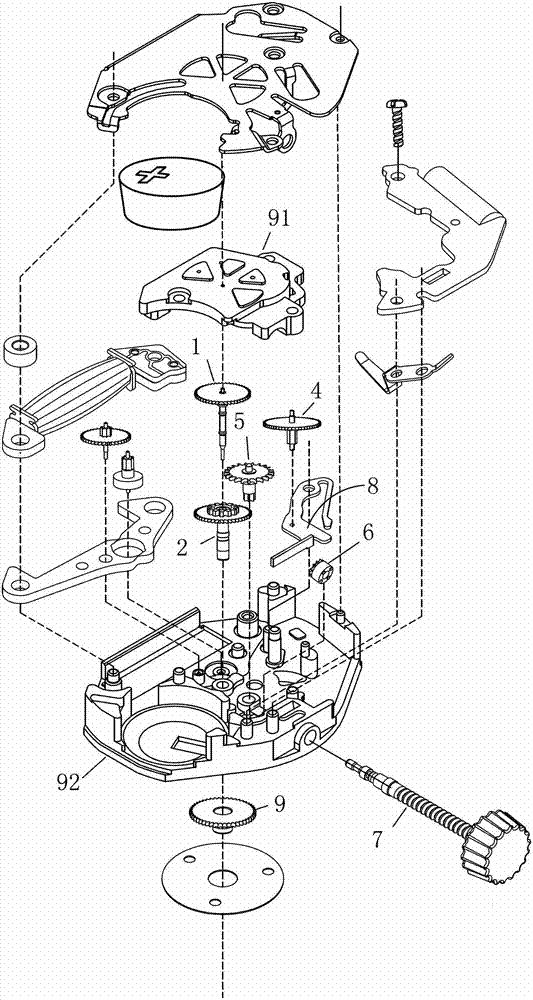

technical field [0001] The invention relates to a quartz watch movement, in particular to a quartz watch movement which omits a clutch lever and a dial intermediate wheel. Background technique [0002] Quartz electronic watches are favored by people for their advantages of accurate travel time, beautiful appearance and eliminating the need for operations such as mechanical watch tightening, but because of the motor, gear train mechanism and other circuit components installed inside the watch case, the space inside the watch case is limited. Large compression, therefore, making full use of the narrow shell space, reducing shell components, reducing component wear and developing more functions has always been a major topic of research and development in the industry, and it is the development direction people are pursuing, especially the stop second clutch mechanism. [0003] Such as figure 1 , 3 , 4, and 5, the second-stop clutch mechanism includes the stem, clutch lever, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G04B13/02G04C3/00

Inventor 吴中一

Owner 吴中一

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com