Tractional load sampling device

A sampling device and mass-moving technology, applied in the direction of sampling devices, etc., can solve problems such as loss of mass-transported samples, damage, and impact on sand transportation conditions, and achieve good flexibility, good representativeness, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

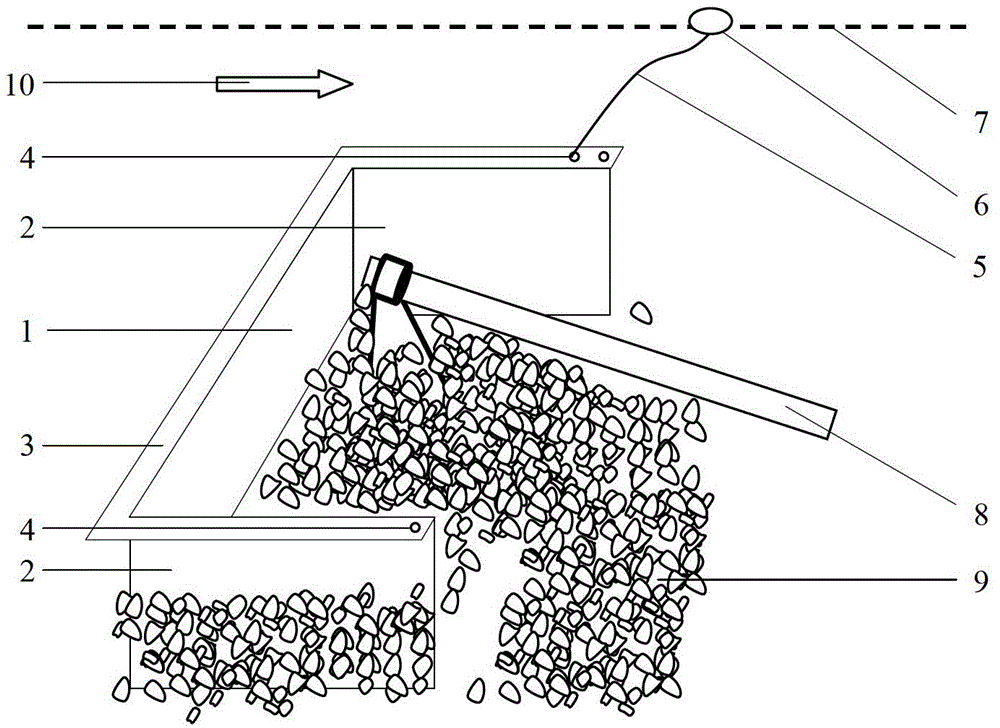

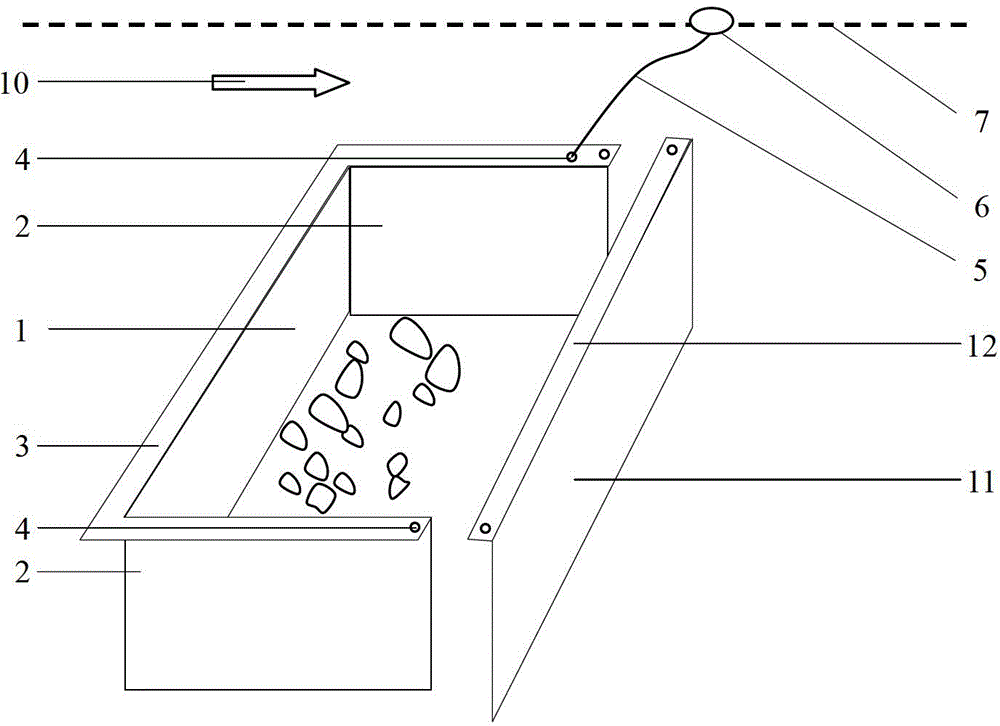

[0040] The structure of the caisson described in Embodiment 1 of the present invention is as follows figure 1 figure 2 , including a front baffle 1, two side baffles 2, a rear baffle 11, and a box cover 20 made of high-strength stainless steel plates. A caisson top frame 3 is arranged on the top of the front baffle 1 and the side baffle 2 . The tailgate 11 has a tailgate top frame 12, and the box cover 20 is as Figure 5 As shown, its specification is consistent with the specification of the outer boundary of the caisson top frame 3 and has a lifting beam 18. The width of the caisson top frame 3 is 4 cm and has a connection hole 4 . The floating display object connecting rope 5 adopts fishing line to make, and the floating display object 6 is a rigid foam material. The inner boundary of the opening of the caisson is 54×33cm, and the height of the caisson is 28cm.

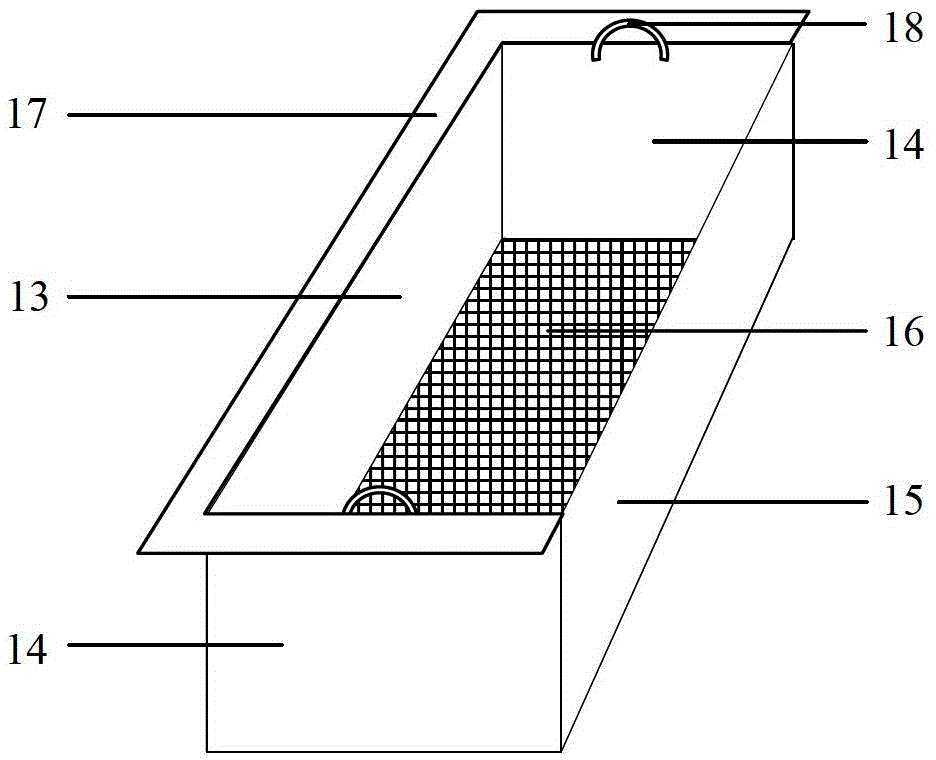

[0041] The structure of the sampling box is as image 3 Shown, be the rectangular box body that has sampli...

Embodiment 2

[0044] The caisson of this embodiment is as Figure 7 , 8 The structure shown has a supporting beam, which makes the structure of the caisson stronger and more suitable for taking drift samples in soft sandy riverbeds. The supporting bottom beam 23 and the supporting top beam 22 are made of a stainless steel triangular profile with a side length of 4 cm. The supporting bottom beam 23 is fixedly connected to the rear end bottoms of the two side baffles 2; the two ends of the supporting top beam 22 are provided with connecting holes 4, which are connected with the connecting holes provided at the two ends of the rear side of the caisson top frame 3. 4. Use connecting parts (such as bolts) for detachable connection. The tailgate 21 is as Figure 6 A handle 18 is shown. The specification of described caisson, sampling box is the same as embodiment 1, and the inner boundary of described caisson box mouth is 54 * 33cm, and height is 28cm; The outer boundary of described sampling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com