Preparation method for high adsorptivity three-dimensional self-assembly graphene

A high-adsorption, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of low adsorption capacity, long-term hydrothermal reaction, etc., achieve convenient operation, shorten hydrothermal reaction time, and simple and fast preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using graphene oxide prepared by the improved Hummers method as a starting material, it was dialyzed in deionized water for 10 days to obtain a graphene oxide aqueous solution. A hydrochloric acid solution with a concentration of 0.6 mol / l was added dropwise to a graphene oxide aqueous solution with a concentration of 1.0 mg / ml until the pH of the solution was 2, and the hydrothermal reaction was carried out at 180 °C for 8 h to obtain a black powder, which was washed with deionized water After washing, the filtered product was freeze-dried for 8 h to obtain the reduced graphene powder.

[0019] The graphene obtained in this example did not form a three-dimensional self-assembled structure after the hydrothermal reaction. As shown in Figure 1, the product was a black powder, and the graphene sheets did not form a certain shape macroscopically.

Embodiment 2

[0021] Using graphene oxide prepared by the improved Hummers method as a starting material, it was dialyzed in deionized water for 10 days to obtain a graphene oxide aqueous solution. A hydrochloric acid solution with a concentration of 0.6 mol / l was added dropwise to a graphene oxide aqueous solution with a concentration of 1.6 mg / ml, adjusted to pH=2, and hydrothermally reacted at 180 °C for 8 h to obtain a cylindrical black hydrogel. After washing with deionized water, the filtered product was freeze-dried for 8 h to obtain the reduced cylindrical graphene.

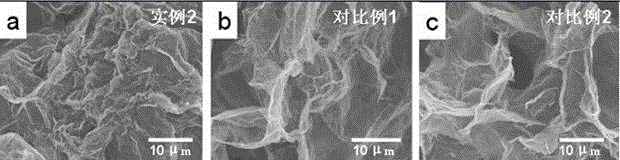

[0022] Three-dimensional self-assembled graphene is prepared under this condition. After hydrothermal reaction and freeze-drying, the sample is cylindrical, as shown in Figure 2. The results of the scanning electron microscope show that the three-dimensional self-assembled graphene is a porous structure. The layer is relatively close, and the pore size is small (1~3 μm), as shown in Figure 3(a). And it has excellent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com