Four-guide pillar type crank shaft flying shear

A technology of crankshaft and four guide columns, which is applied in the field of flying shears, can solve the problems of low precision of flying shears, and achieve the effects of high guiding precision, high applicable frequency and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

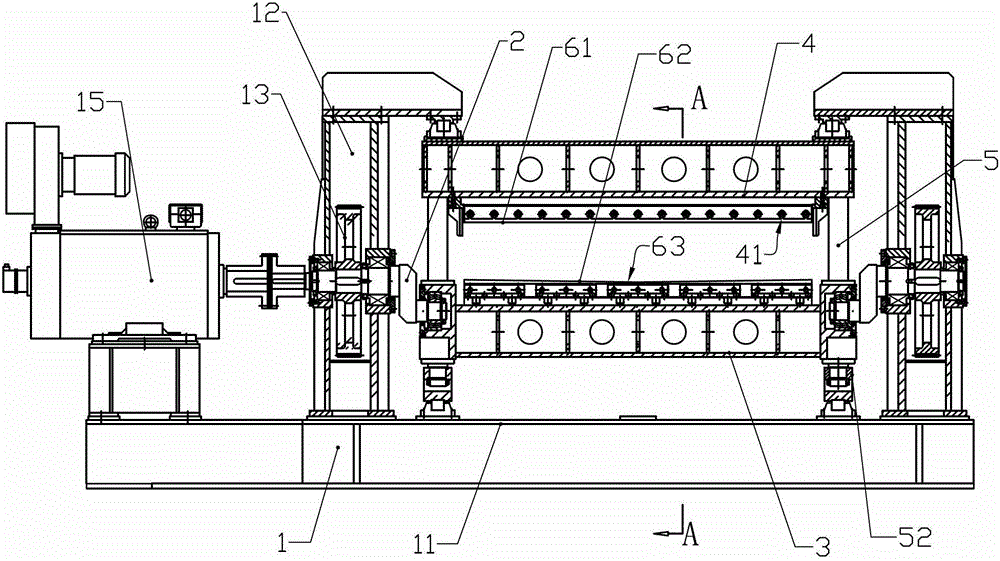

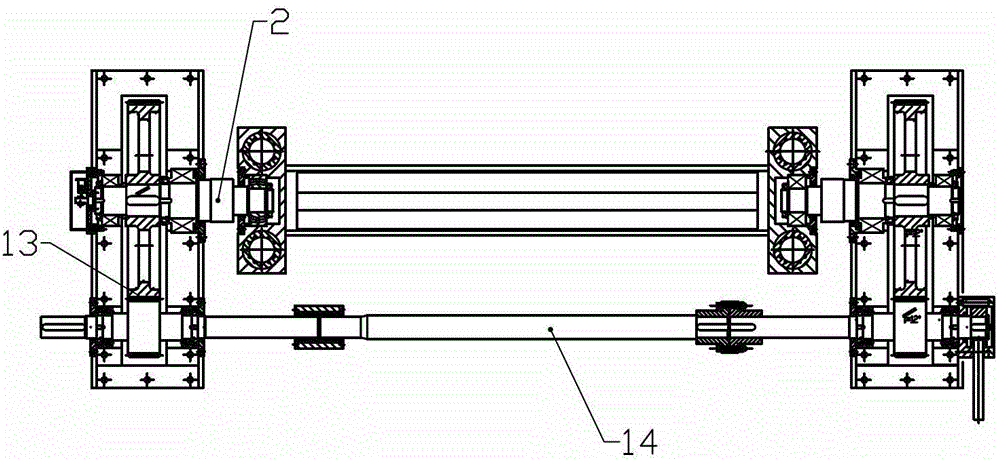

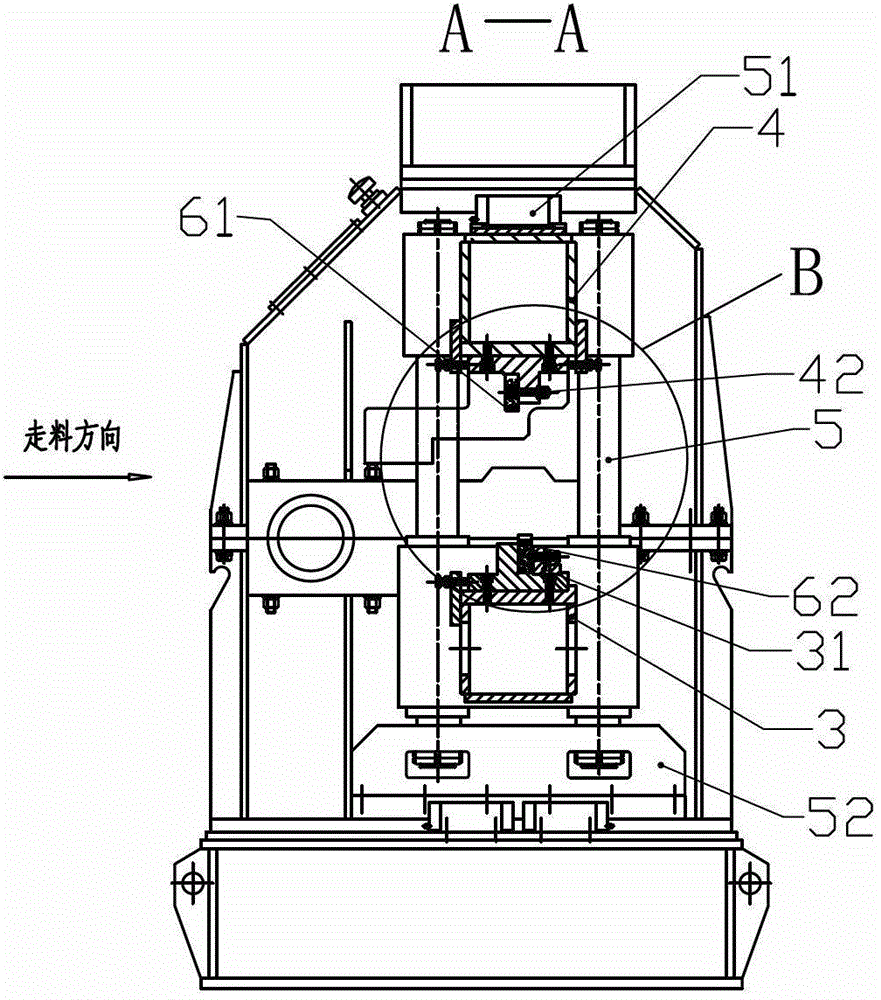

[0017] Such as Figure 1 to Figure 6 as shown,

[0018] A four-column type crankshaft flying shear comprises a machine base, an upper knife rest, a lower knife rest, a crankshaft, a driving motor, a gear transmission mechanism and upper and lower flying shears.

[0019] The base 1 includes a base 11 and a gear box 12 installed on both sides of the base. Two groups of helical gear assemblies 13 are installed in the gear box. Motor 15 is directly connected directly by shaft coupling, and bull gear is arranged on the outer end of crank shaft, and crank shaft 2 is installed in the gear box by bearing, and two crank shafts 2 are connected on both sides of lower tool rest 3 by bearing simultaneously. In this way, the entire transmission system is formed.

[0020] The drive motor 15 drives the two crank shafts to rotate through the gear transmission mechanism, and the flying shears are installed on the upper and lower tool rests to realize the effect of the flying shears.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com