Device for picking tobacco leaf from top to bottom of tobacco plant

A technology for tobacco leaves and tobacco plants, applied in harvesters, agriculture, applications, etc., can solve the problems of not being able to complete picking tasks in time, inconvenient maintenance, and high production costs, saving labor costs, reducing labor intensity, and picking net rates. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

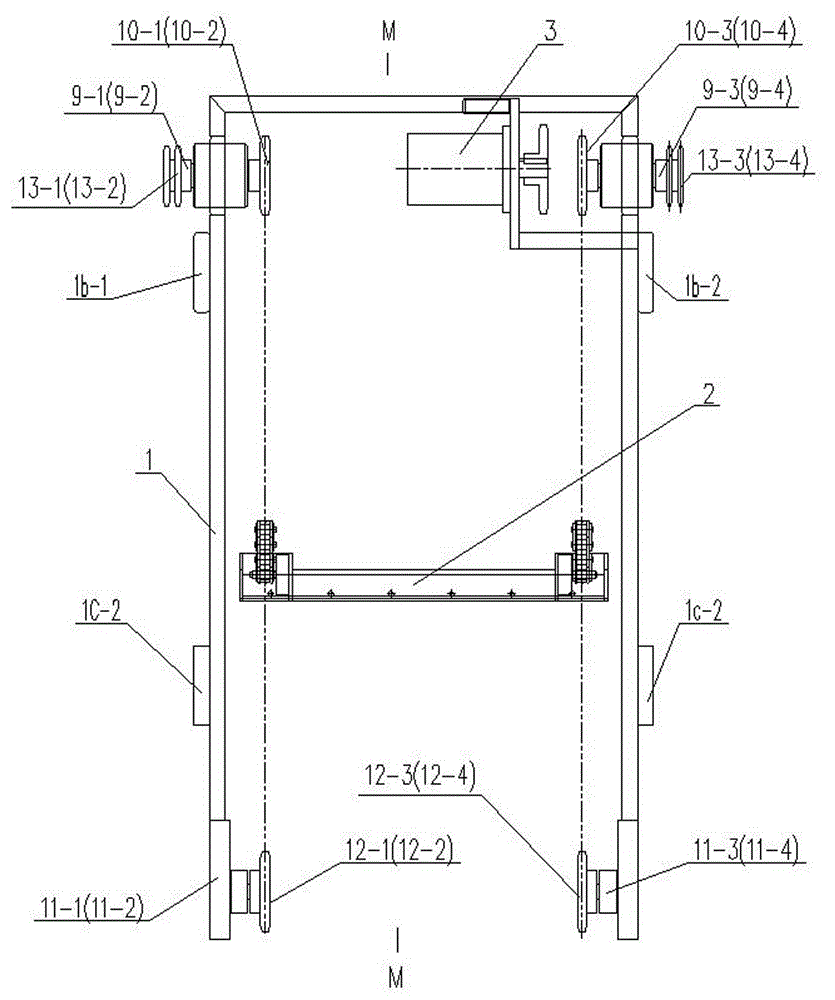

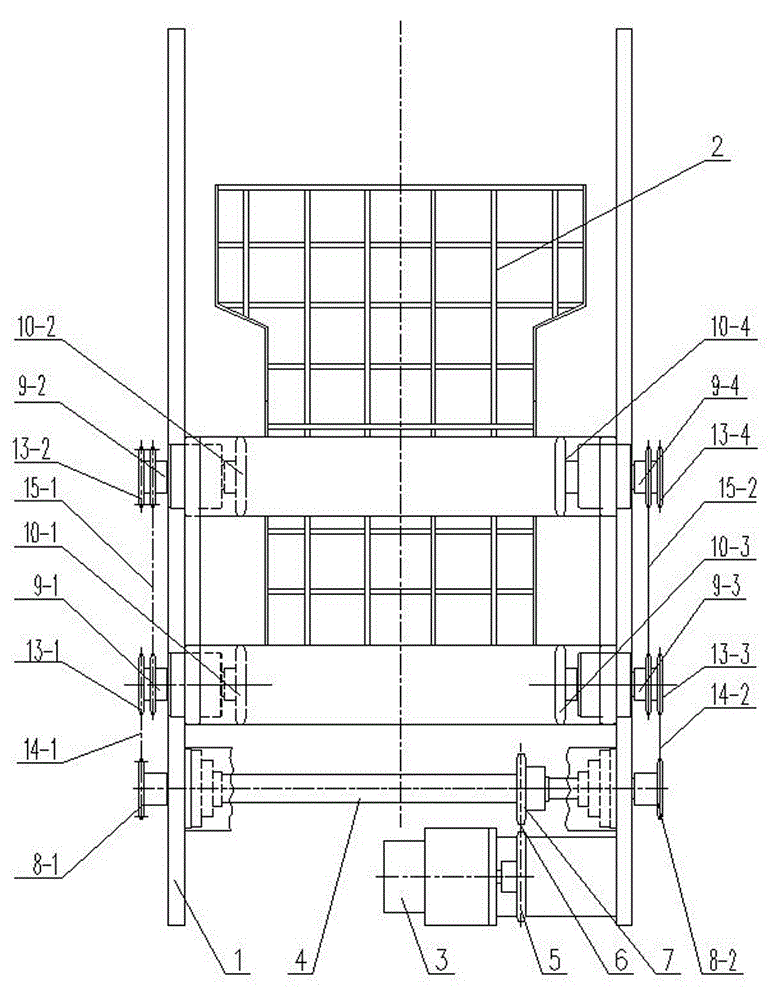

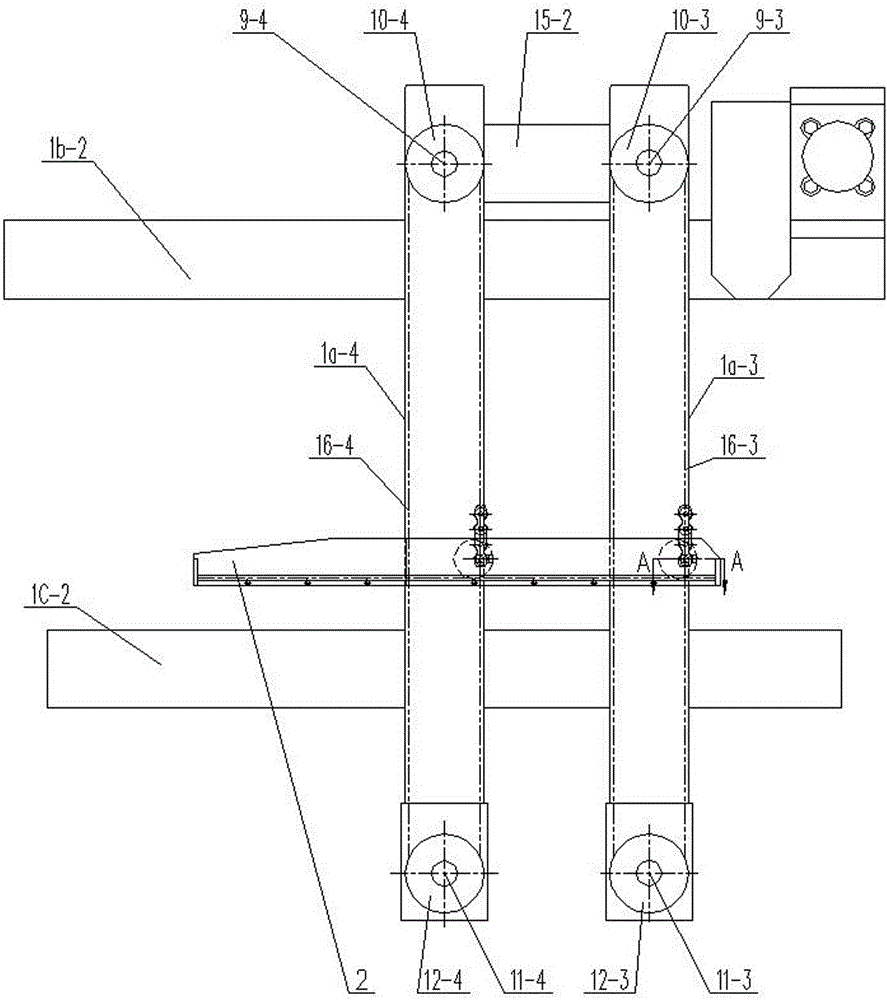

[0015] Such as Figure 1-Figure 5 As shown, the present invention includes a gantry hanger 1, a grid-type horizontal leaf frame 2 arranged in the hanger, a sprocket system that drives the leaf frame to move up and down, and a drive device 3 that can drive the sprocket system forward and backward. . Drive device 3 adopts hydraulic motor. The side beams on both sides of the hanger 1 can be a plate structure, and the first chain wheel group 8-1, 8-2, the second chain wheel group 10-1, 10-2, 10-3, 10-4, the third chain wheel group Sprocket set 12-1, 12-2, 12-3, 12-4, fourth sprocket set 13-1, 13-2, 13-3, 13-4, second transverse shaft set 9-1, 9 -2, 9-3, 9-4, and the third transverse shaft group 11-1, 11-2, 11-3, 11-4 are all symmetrically installed on the longitudinal beams on both sides. Hanger 1 also can include two on each side and four longitudinal beams 1a-1, 1a-2, 1a-3, 1a-4 that are symmetrically arranged on both sides as shown in this embodiment, two on each side The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com