Molded surface regulating device and regulating method of honeycomb sandwich structure high-accuracy panel

A honeycomb interlayer, high-precision technology, applied in the direction of using feedback control, etc., to achieve the effect of improving the accuracy of assembly and adjustment, and improving the accuracy of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

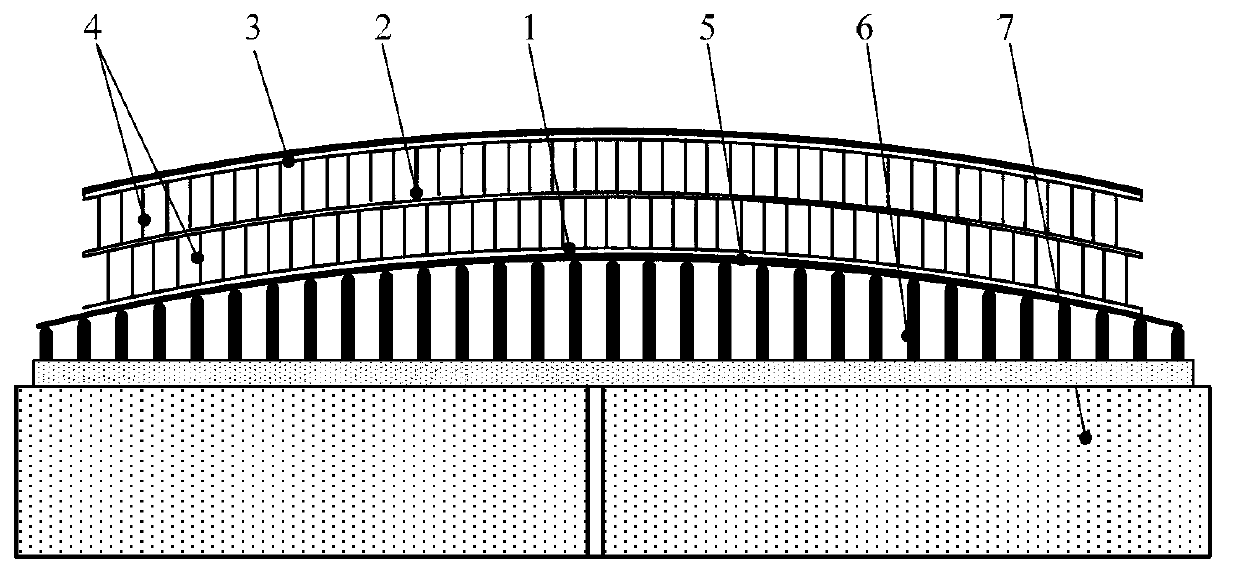

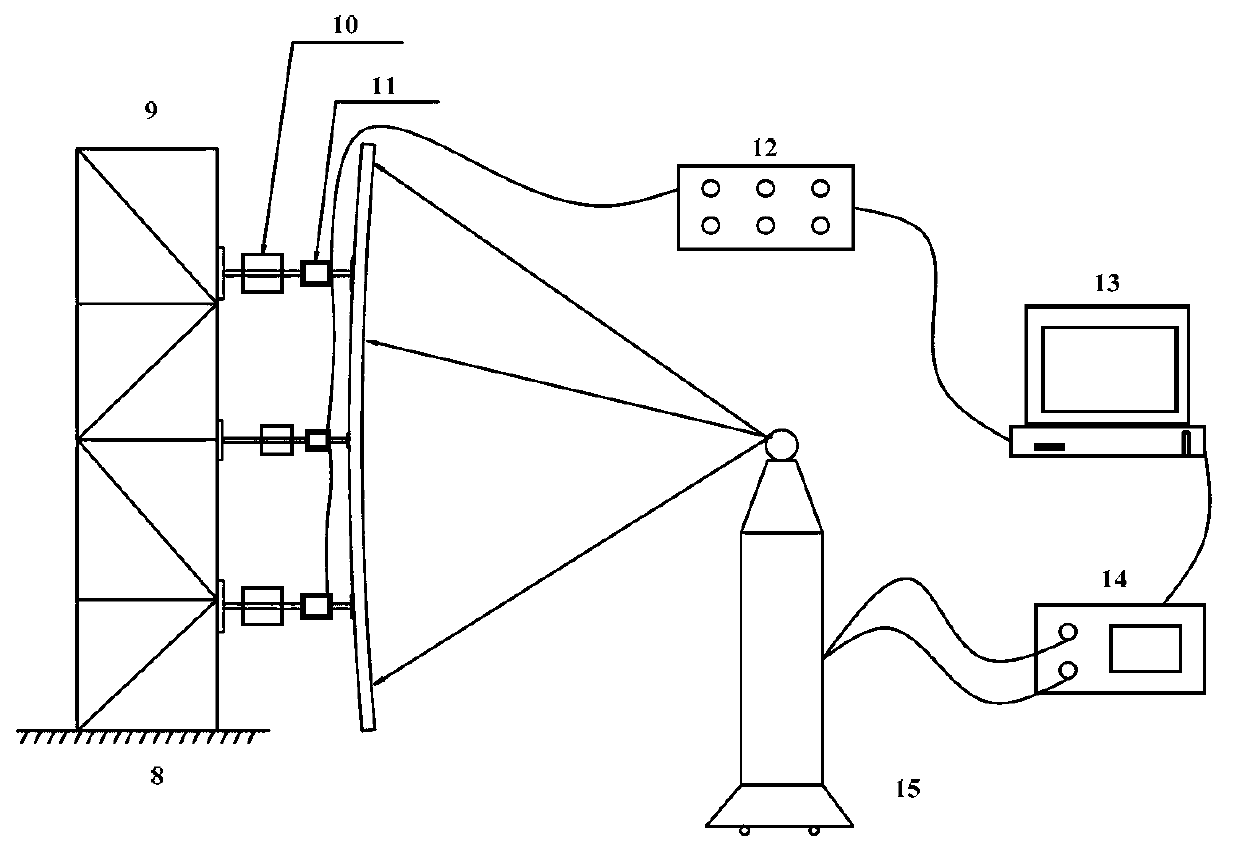

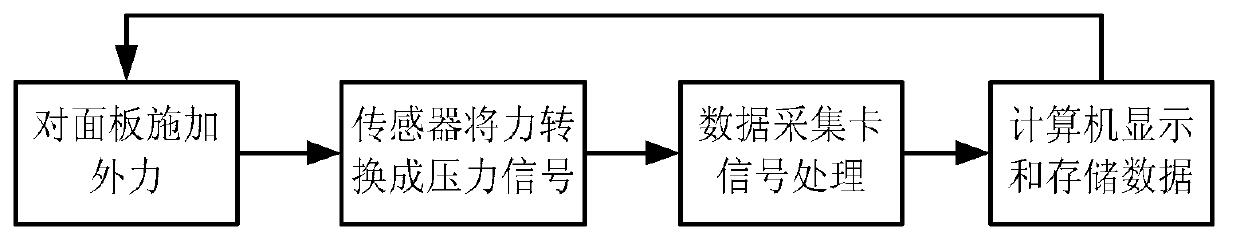

[0044] (1) see figure 2 , the present invention is a profile adjusting device for a high-precision panel with a honeycomb sandwich structure, which includes a mechanical system composed of a back frame and a connecting rod mechanism supporting the panel, a profile composed of a laser tracker measuring host, a control host, and a notebook computer. Accuracy measurement system and acquisition system of key parameters of surface accuracy composed of force sensor, parameter acquisition system and notebook computer. The positional connection relationship between them is: the back frame is connected to the foundation through anchor bolts, part of the linkage mechanism is connected to the back frame through bolts, and the other part is connected to the reinforcement plate on the back of the high-precision panel through screws and screw holes. The two ends are respectively connected to the threaded rods of the linkage mechanism through screw holes to realize data collection during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com