Turnover positioning mechanism

A positioning mechanism and positioning component technology, applied to the locking device, measuring device, instrument, etc. when the movable parts of the measuring device are not in use, can solve production quality problems, the impact of the next step of the turning station, and the turning accuracy cannot be strictly controlled, etc. problems, to achieve the effect of convenient control, repeated work times, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

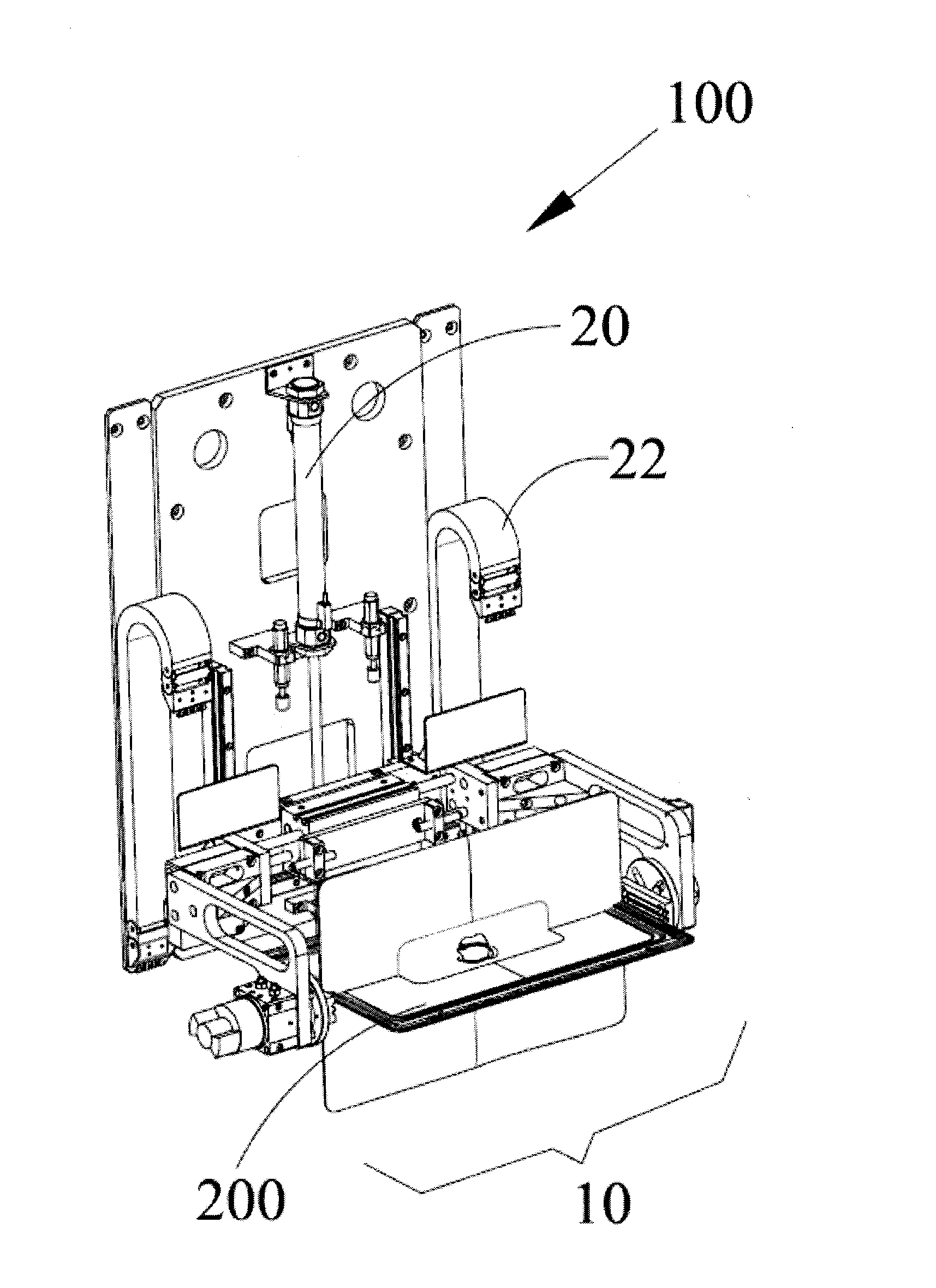

[0025] ginseng figure 1 As shown, the turning machine 100 of the present invention includes:

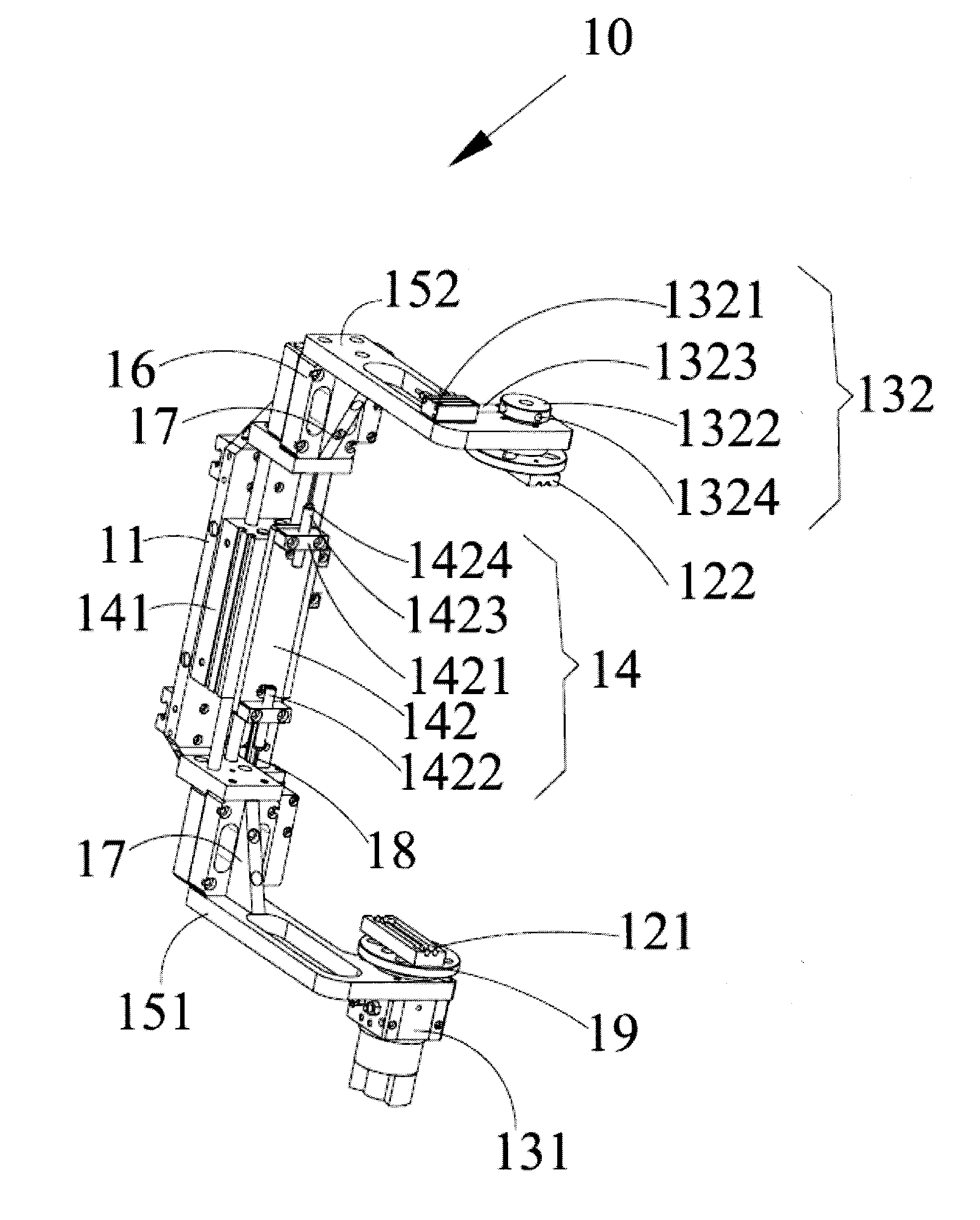

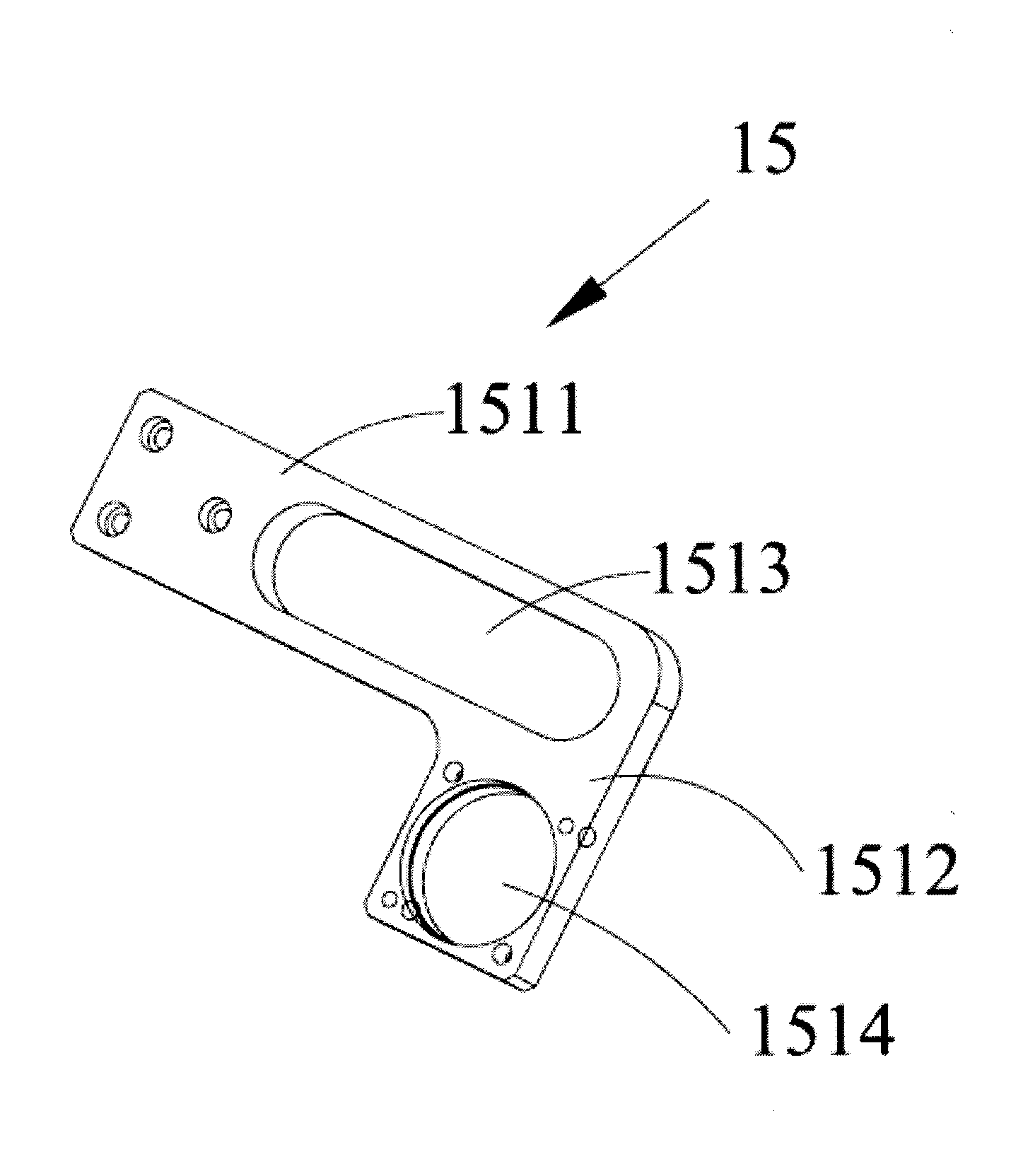

[0026] An overturning assembly 10, which includes a clamping member 12 for clamping a workpiece 200, and a power component for controlling the overturning of the clamping member 12;

[0027] Pulling the assembly 20 drives the turning assembly 10 to move up and down. The moving area of the turning assembly 10 includes the first position located at the uppermost end of the moving area. When the turning assembly moves to the first position, its power component turns over The clamping member 12 drives the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com