Multi-corner tangential multi-scale pulverized coal decoupling combustion device and decoupling combustion method thereof

A technology of a combustion device and a combustion method, which is applied in the direction of combustion methods, combustion using various fuels, combustion using block fuels and powder fuels, etc., which can solve problems such as burner life reduction, loss of function, and erosion wear, and achieve increased Uniformity, reduction of fly ash combustibles and NOx emissions, and the effect of overcoming coupling emissions of pulverized coal combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings.

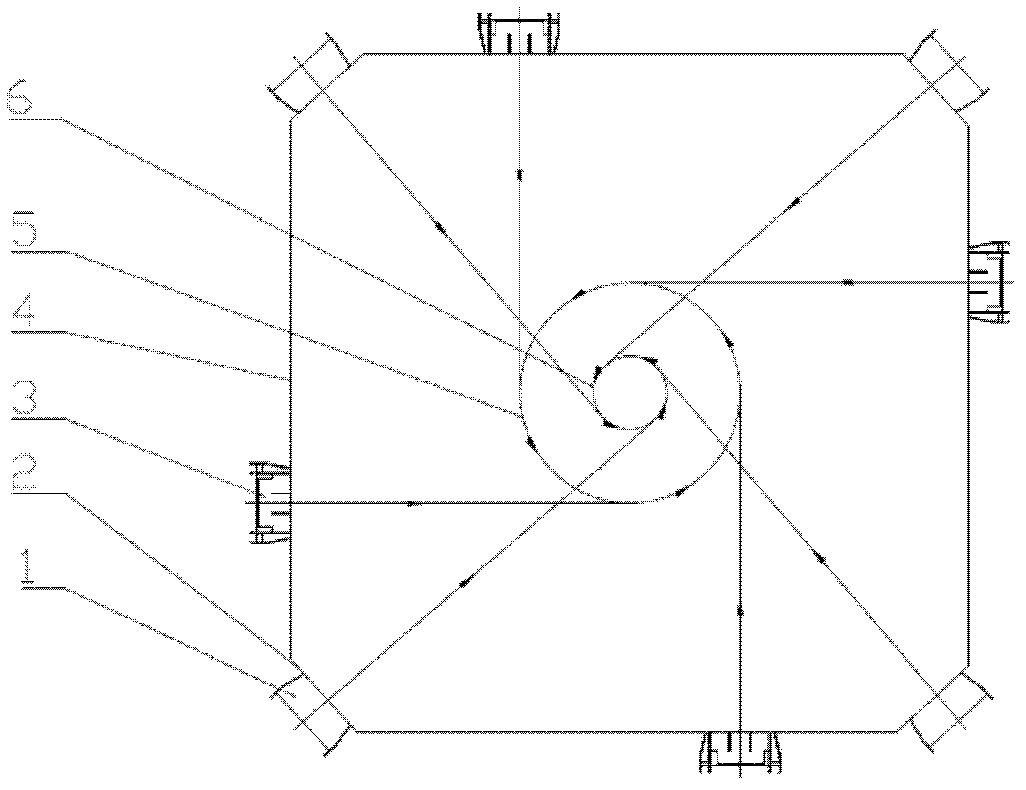

[0060] Such as figure 1 As shown, the multi-angle tangential circle multi-scale pulverized coal decoupling combustion device in this embodiment adopts a four-corner tangential circle pulverized coal decoupling combustion furnace, four rows of primary air nozzles 3, primary secondary air nozzles 7 and their centers burn out The air nozzles 9 are installed on the four furnace side walls 4, and correspondingly, four rows of secondary air nozzles 1 and their peripheral burn-off air nozzles 8 are installed on the four furnace corner walls 2;

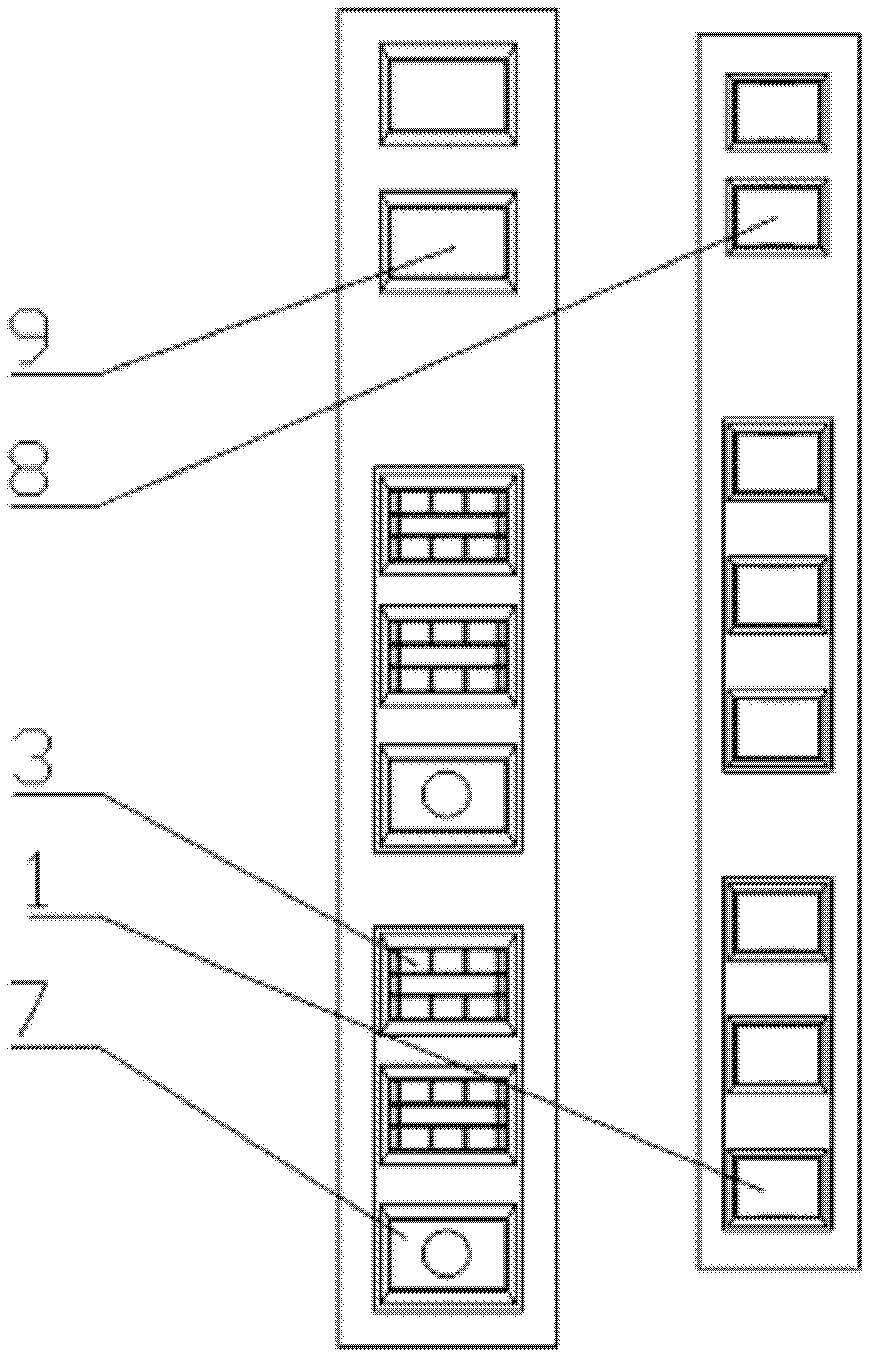

[0061] Such as figure 2 As shown, the primary air nozzle 3 can adopt a coal powder decoupling burner, and adopts a local centralized arrangement method, and two or more primary air nozzles 3 adjacent to each other form a group and are arranged on the furnace side wall 4; A small oil gun or plasma ignition device for ignit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com