No-tooth transmission lead screw with adjustable polish rod axis positions and transmission friction force

A technology of driving friction force and driving screw, applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the difficulty of adjusting the friction force, the axis position of the toothless screw can not be fine-tuned, the manufacturing cost High problems, to achieve the effect of low cost, low wear and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The toothless screw rod of this patent will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

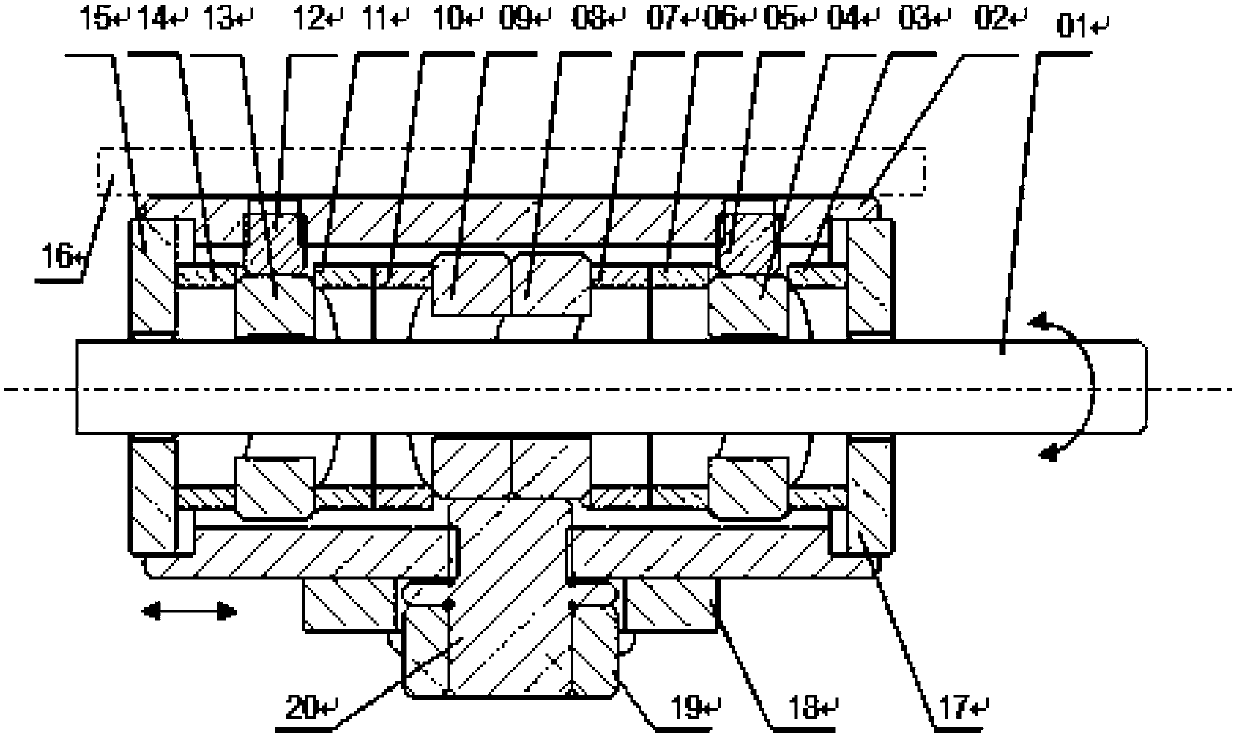

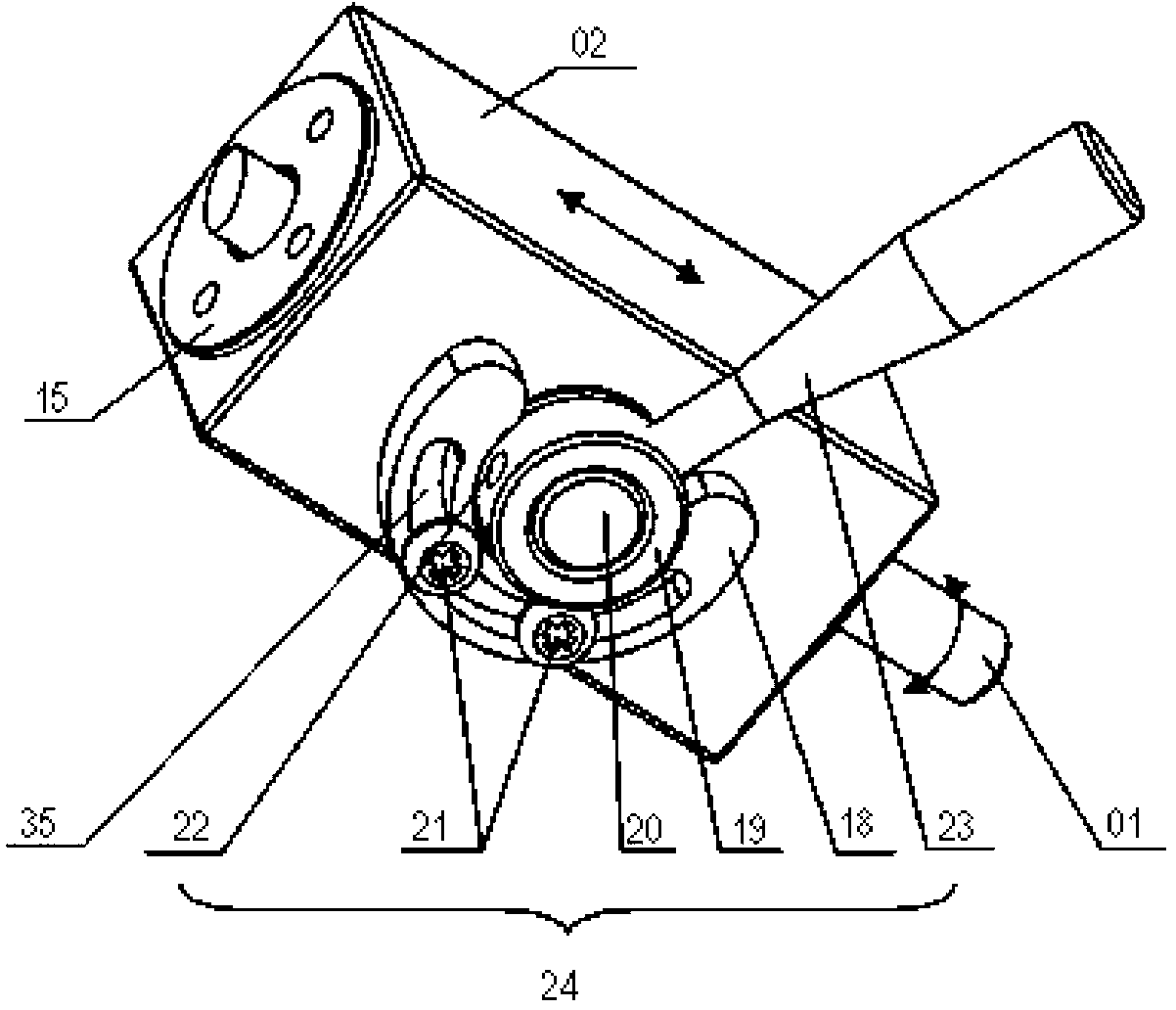

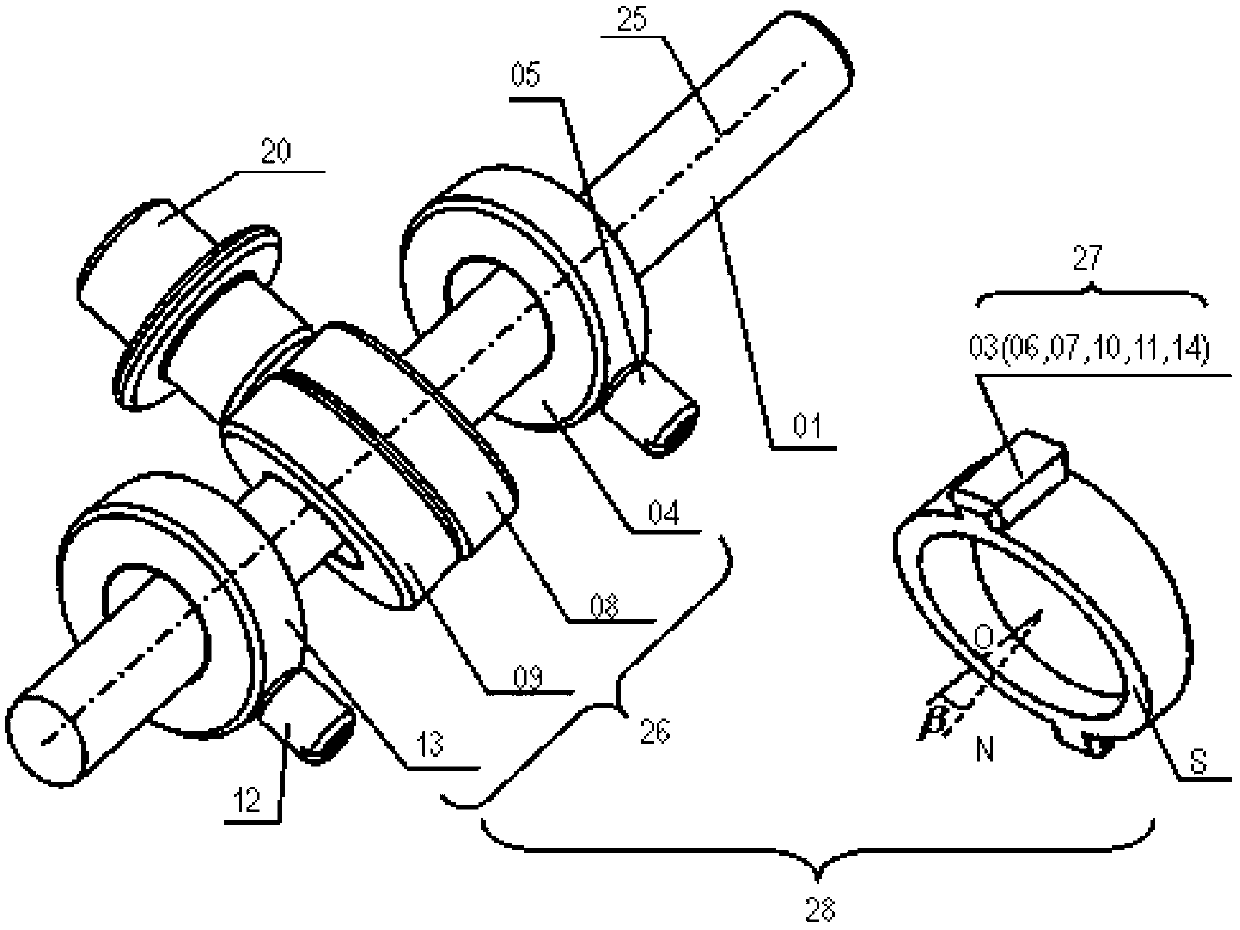

[0026] likefigure 1 , figure 2 and image 3 As shown, the toothless screw rod with adjustable axial position and friction force of the polished rod of the present invention includes a polished rod 01, a displacement block 02 that moves in parallel along its axis, and a displacement platform 16 that is connected with the displacement block and moves together, and is placed in the inner cavity of the displacement block The friction transmission pair 28 composed of the polished rod 1, the bearing group 26 and the wedge block group 27 presses the adjusting screws 05 and 12 on the bearing group 26 to adjust the axial position of the polished rod, and is responsible for adjusting the frictional force, locking and Loosen the pressing bolt group 24 of the transmission pair. The polished rod 01 is driven by manual rotation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com