Fire damper for secondary detonation-breathing pulse detonation engine

A technology of pulse detonation and fire baffle, applied in the field of fire baffle, can solve the problems of reducing the stability of pulse detonation engine, large forward flow resistance loss, complex anti-reflux mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is a fire baffle for a secondary detonation air-breathing pulse detonation engine.

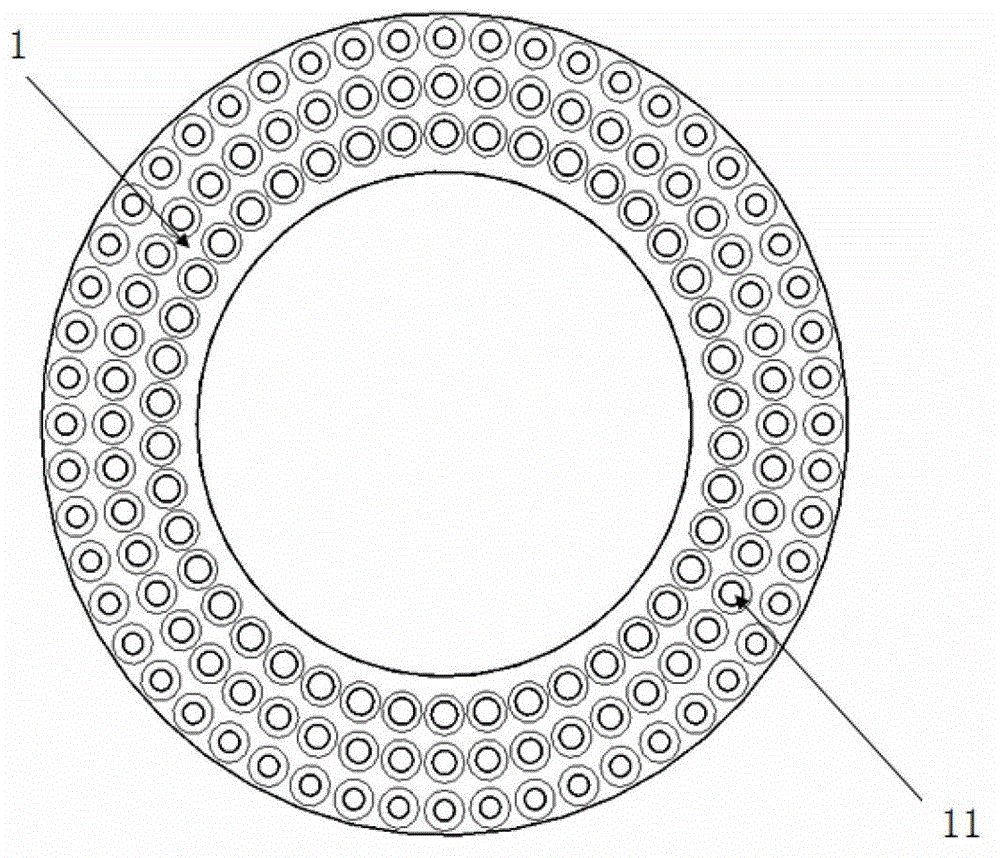

[0019] refer to figure 1 , figure 2 , the fire baffle of the present invention's secondary detonation air-breathing pulse detonation engine, the fire baffle body 1 is annular, the front end surface is a plane, and the center of the fire baffle body 1 is extended on the ring body. Several circles of the same tapered holes 11, the circumferential spacing between several identical tapered holes 11 is equal; the rear end surface 3 of the fire baffle is a spherical structure, and the radius of the sphere is equal to the radius of the fire baffle body 1; the fire baffle body 1 The outer diameter of the fire baffle body 1 is equal to the inner diameter of the ejector straight pipe 8, the inner diameter of the fire baffle body 1 is equal to the outer diameter of the pre-explosion pipe 9, and the fire baffle body 1 is fixedly installed on the pre-explosion pipe 9 and is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com