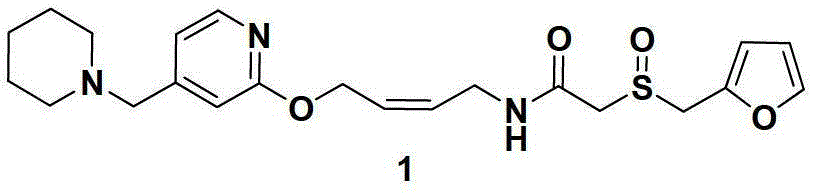

The method that hydroxylamine hydrochloride prepares lafutidine

A technology of hydroxylamine hydrochloride and lafutidine, which is applied in the direction of organic chemistry, can solve the problems of increasing costs, and achieve the effect of improving safety, high purity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

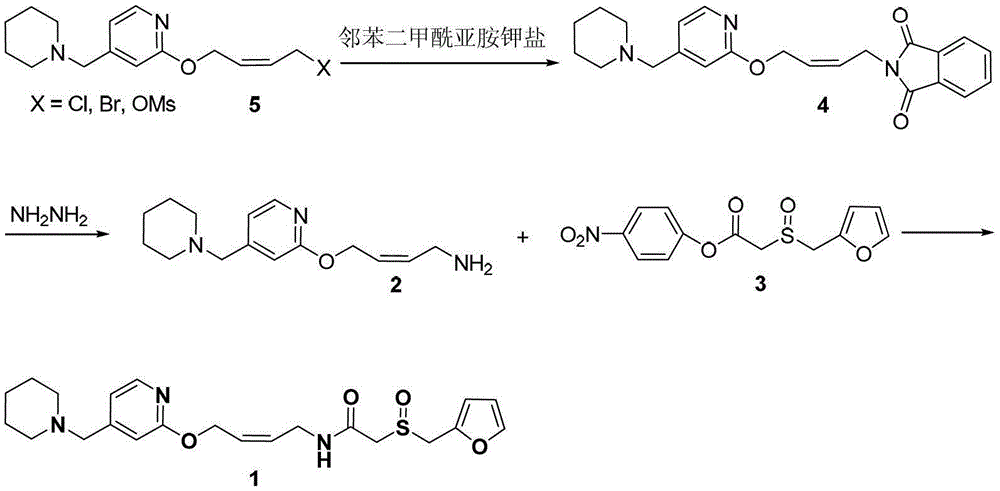

Method used

Image

Examples

Embodiment 1

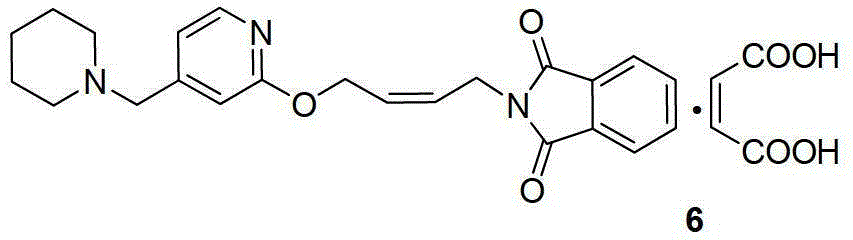

[0039] Embodiment 1: N-[cis-4-[4-(N-piperidinylmethyl)pyridine-2-oxygen]-2-buten-1-yl]phthalimide (compound of formula 4) preparation of

[0040] Take 100g (0.197mol) of maleate salt (compound of formula 5), add 1 liter of water, stir at room temperature for 15 minutes, add sodium hydroxide to adjust the pH to about 12, extract with 500mL of dichloromethane, separate layers, and then use 250mL of dichloromethane Extract with methyl chloride, combine the organic phases, dry over anhydrous sodium sulfate, filter, and evaporate the solvent to give 74.7g of viscous liquid (Compound 4), with a yield of 96.8% (based on crude product)

Embodiment 2

[0041] Example 2: Preparation of N-[cis-4-[4-(N-piperidinylmethyl)pyridine-2-oxygen]-2-butene-1-amine (compound of formula 2)

[0042]In a 500mL three-necked flask, 20 g (0.05 mol) of the imine (the compound of formula 4 prepared in Example 1), 94 g of ethanol, and 21.4 g (0.31 mol) of hydroxylamine hydrochloride were added to produce a large amount of white solid, and then aqueous sodium hydroxide ( Contains sodium hydroxide 51g, 1.27mol), react at room temperature for about 1 hour. After the TLC detection reaction was complete, add 400 mL of water to the reaction solution, extract 200 mL × 2 with dichloromethane, combine the organic phase, wash 200 mL with water, dry the organic phase with anhydrous sodium sulfate, filter, and concentrate to dryness to obtain 13.2 g of light yellow oil ( Compound 2) has a yield of 95.5%, HPLC 98.9%, and is used in the next step without further purification.

Embodiment 3

[0043] Example 3: (+ / –)-2-[(2-furylmethyl)sulfinyl]-N-[4-[4-(1-piperidinylmethyl)-2-pyridyl]oxy Synthesis of Sub-(Z)-2-butenyl]acetamide (compound of formula 1, lafutidine)

[0044] Add 70 mL of ethyl acetate to 13.2 g (0.05 mol) of the oily enamine (compound of formula 2) obtained in Example 2, stir to dissolve, and then add p-nitrophenol 2-furan methanesulfonyl acetate (compound of formula 3 ) 15.6g (0.05mol, HPLC purity 99.5%), stirred and reacted at room temperature for 3-4 hours, TLC detected that the reaction was complete. Add 100 mL of water, adjust the pH to 4 with concentrated hydrochloric acid, filter, and separate layers. Add 150 mL of dichloromethane to the water phase, add potassium carbonate to adjust the pH to about 10, and separate layers. Add 80 mL of dichloromethane to the water layer for extraction. Combine the organic phases, wash with 30% potassium carbonate solution (100mL×4), wash with water (100mL×5), separate the organic phase, dry over anhydrous sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com