Installation device for sprayer nozzle

A technology for installing devices and nozzles, which is applied in printing and other directions, and can solve problems such as inconsistent printing effects, inability to adjust nozzle positions, and affecting printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

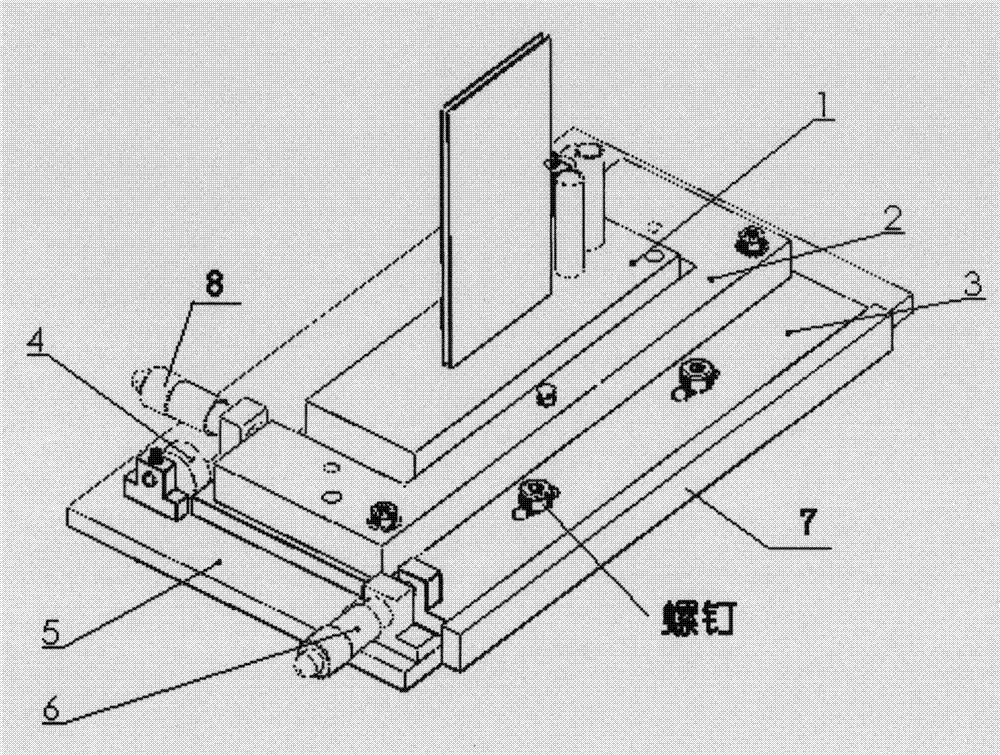

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

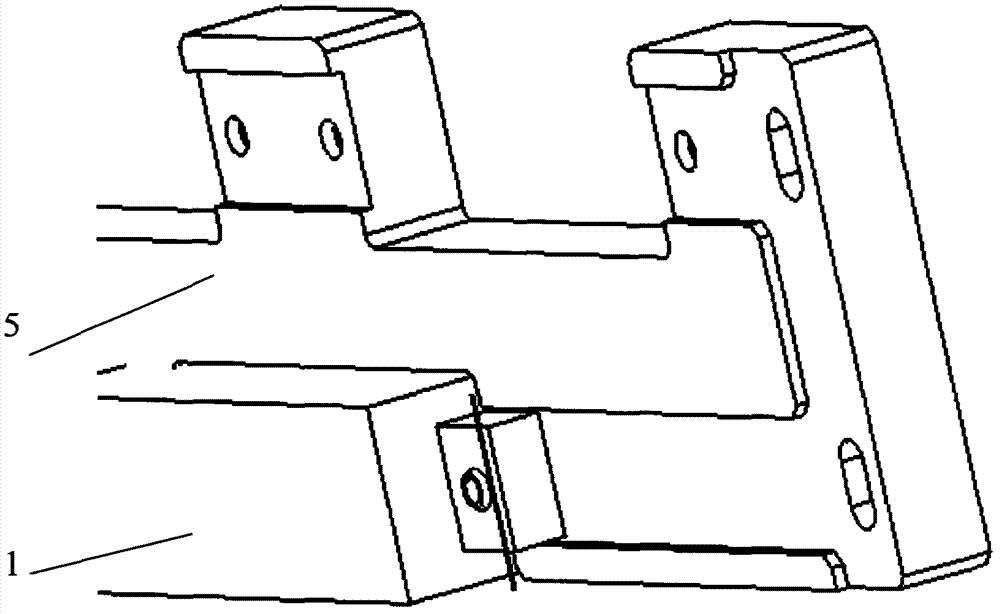

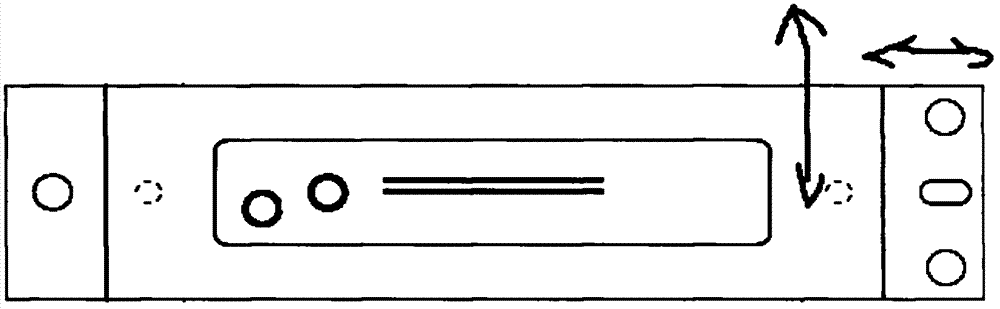

[0017] figure 2 Shown is the assembly top view according to the embodiment of the present invention, and installation device comprises bottom plate (not shown) and clamping block, and shower head 1 is fixedly installed on the clamping block by connector, and clamping block is installed on the bottom plate 5, and clamping block and bottom plate The assembly area between them is larger than the assembly area between the shower head 1 and the clamping block.

[0018] In the prior art, the spray head 1 is directly fixed on the bottom plate 5 . However, due to the small size of the nozzle, the assembly area provided is relatively small, so the processing accuracy of the mounting parts has a great influence on the accurate installation of the nozzle. And in this embodiment, the nozzle is transferred to the floor through the clamp block,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com