Force transmission device

A technology of transmitters and integrated modules, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficult joints, affecting operations, and high labor intensity, so as to simplify operations and maintenance and facilitate standardization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

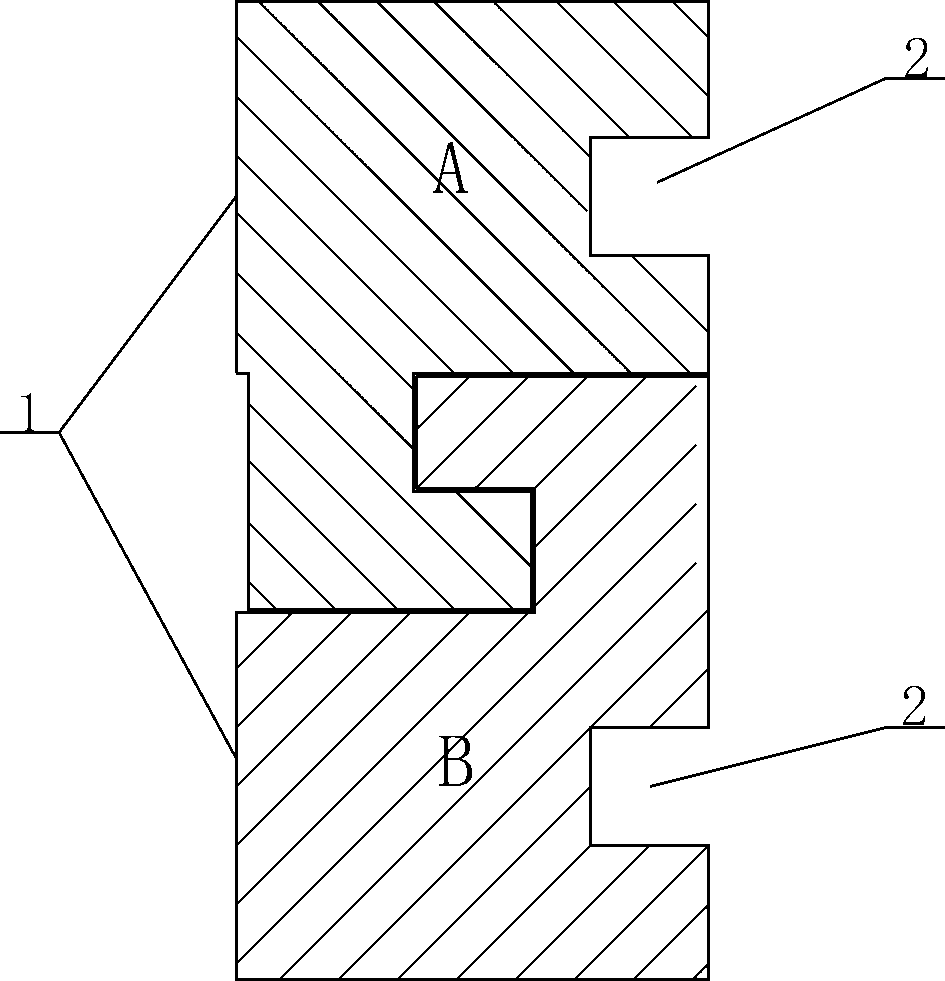

[0017] Taking four modules (1) combined into an integrated module (4) as an example, sub-module A and sub-module B are represented by " The "shape contact surfaces bite together into modules (1), and the other three modules (1) are snapped together according to the above-mentioned method. The positions of sub-module A and sub-module B of two adjacent modules (1) are opposite up and down, and the four The modules (1) are combined into an integrated module (4), and the waist support belt (5) is placed in the belt support groove (3) and fastened tightly, which constitutes the static state of the force transmitter.

[0018] When using and maintaining, find out the corresponding model from the series of force transmitters according to the force and the requirements of the working environment, and open the waist belt (5), so that the integrated module (4) is dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com