Gas mixing and distributing structure of double-chamber or multi-chamber thin film deposition equipment

A technology of thin film deposition and gas mixing, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high cost, complex structure, large space occupation, etc., and achieve convenient installation and maintenance, low cost, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

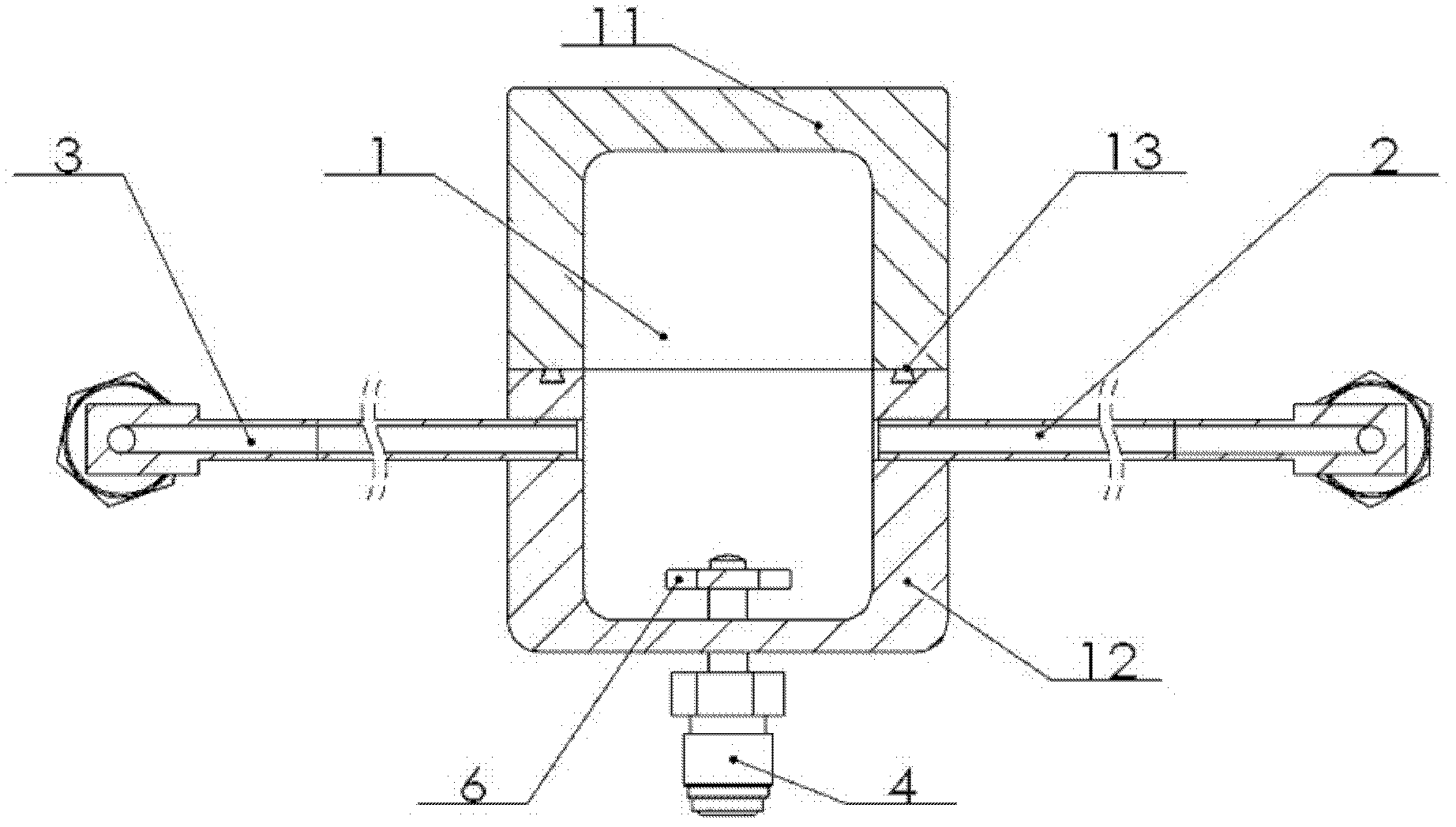

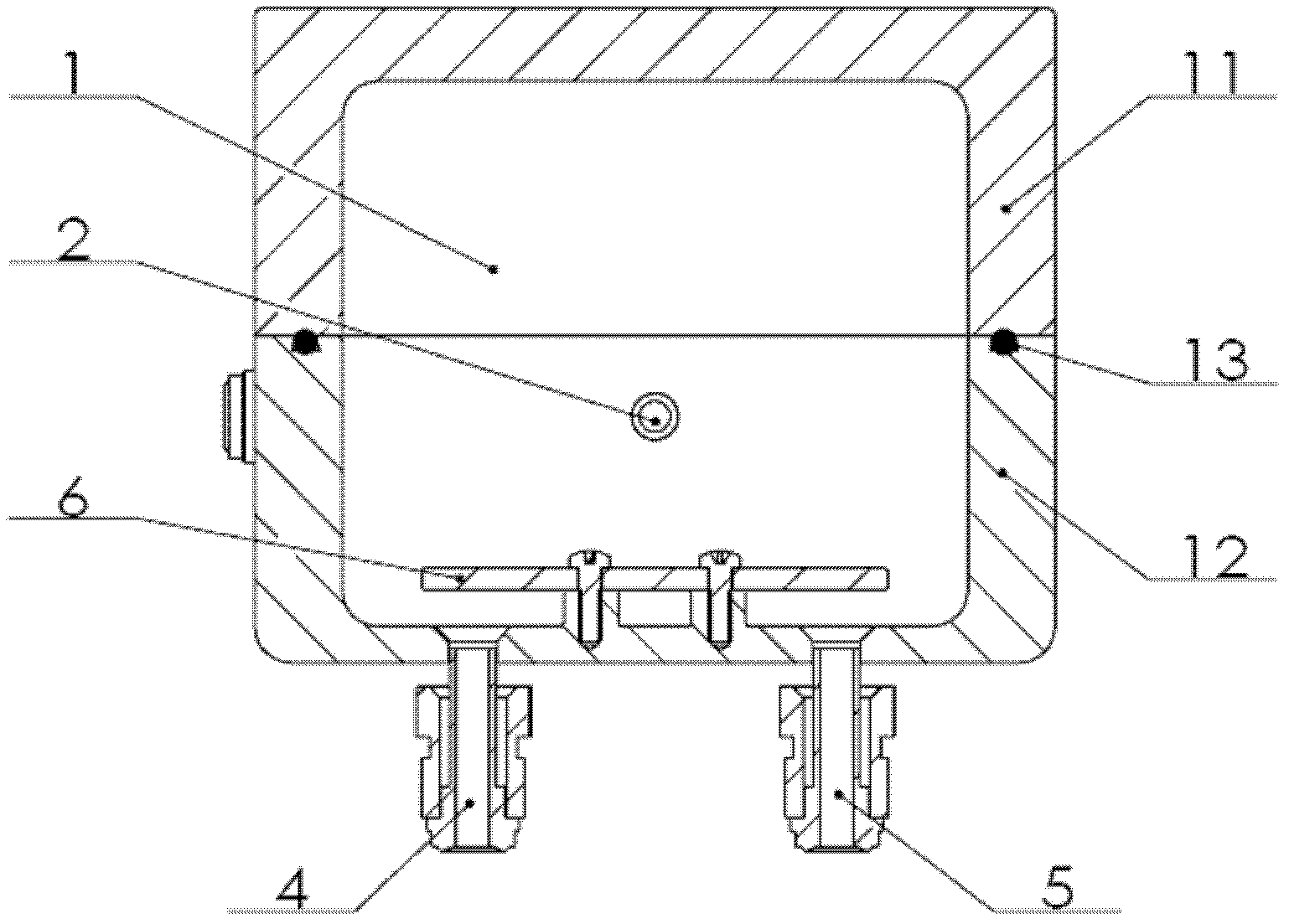

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , figure 2 As shown, the present invention includes a gas mixing chamber 1, a gas inlet pipeline, a gas outlet pipeline and an inlet baffle 6, wherein the gas mixing chamber 1 is an axisymmetric geometric body, such as a cuboid or a cylinder, and the gas mixing chamber 1 can be The integrated structure can also be a horizontal split structure. The gas mixing chamber 1 of this embodiment is a horizontal split structure, which is divided into the upper half of the gas mixing chamber 11 and the lower half of the gas mixing chamber 12, and the middle part is sealed by a sealing rubber ring 13. connect.

[0018] The bottom surface of the gas mixing chamber lower half 12 is connected with a first gas inlet pipeline 4 and a second gas inlet pipeline 5, and the first gas inlet pipeline 4 and the second gas inlet pipeline 5 are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com