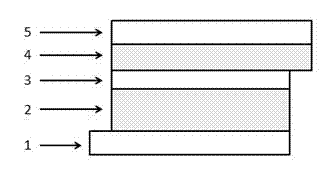

Double-side light entering quantum dot sensitization solar cell and preparation method thereof

A technology for quantum dot sensitization and solar cells, which is applied in the field of quantum dot sensitization solar cells and its preparation, to achieve the effects of promoting industrialization, benefiting battery performance, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Wash. In the test, the FTO conductive glass substrate should be cleaned and dried first. First, cut the conductive glass to the required size with a glass knife, clean it with a detergent, and then rinse it with deionized water. Then place it in an ultrasonic cleaner and use acetone-free, ethanol, and ionized water to ultrasonically clean it for 10 minutes, and finally dry it with nitrogen to obtain the substrate with a clean surface required for the experiment.

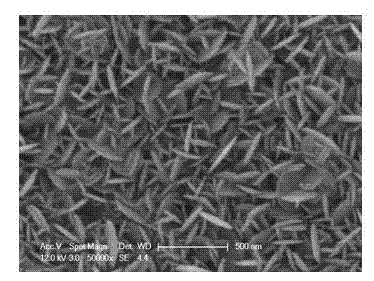

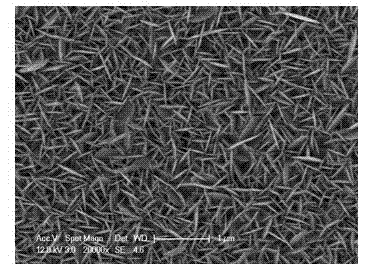

[0035] 2) Preparation of quantum dot-sensitized photoanode. Scrape-coat a layer of pre-prepared TiO on clean FTO 2 slurry, sintered at 450 °C for 30 min to form TiO 2 Porous layer, repeated scraping until TiO 2 After reaching about 12 μm, the sintered photoanode is sequentially deposited three layers of CdS, five layers of CdSe, and two layers of ZnS quantum dots through a chemical bath, and finally washed thoroughly with deionized water, and then dried in an oven at 50 ° C. use.

[0036] 3) Prepare t...

Embodiment 2

[0041] 1) Wash. In the test, the FTO conductive glass substrate should be cleaned and dried first. First, cut the conductive glass to the required size with a glass knife, clean it with a detergent, and then rinse it with deionized water. Then place it in an ultrasonic cleaner and use acetone-free, ethanol, and ionized water to ultrasonically clean it for 10 minutes, and finally dry it with nitrogen to obtain the substrate with a clean surface required for the experiment.

[0042] 2) Preparation of quantum dot-sensitized photoanode. Scrape-coat a layer of pre-prepared TiO on clean FTO 2 slurry, sintered at 450 °C for 30 min to form TiO 2 Porous layer, repeated scraping until TiO 2 After reaching about 12 μm, the sintered photoanode is sequentially deposited three layers of CdS, five layers of CdSe, and two layers of ZnS quantum dots through a chemical bath, and finally washed thoroughly with deionized water, and then dried in an oven at 50 ° C. use.

[0043] 3) Prepare t...

Embodiment 3

[0048] 1) Wash. In the test, the FTO conductive glass substrate should be cleaned and dried first. First, cut the conductive glass to the required size with a glass knife, clean it with a detergent, and then rinse it with deionized water. Then place it in an ultrasonic cleaner and use acetone-free, ethanol, and ionized water to ultrasonically clean it for 10 minutes, and finally dry it with nitrogen to obtain the substrate with a clean surface required for the experiment.

[0049] 2) Preparation of quantum dot-sensitized photoanode. Scrape-coat a layer of pre-prepared TiO on clean FTO 2 slurry, sintered at 450 °C for 30 min to form TiO 2 Porous layer, repeated scraping until TiO 2 After reaching about 12 μm, the sintered photoanode is sequentially deposited three layers of CdS, five layers of CdSe, and two layers of ZnS quantum dots through a chemical bath, and finally washed thoroughly with deionized water, and then dried in an oven at 50 ° C. use.

[0050] 3) Prepare t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com