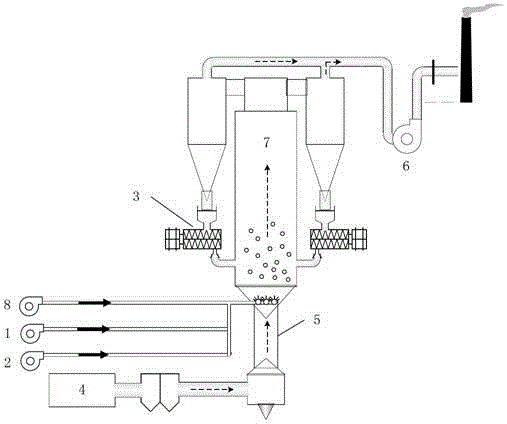

Multi-objective optimization method of desulfurizer pre-injection in circulating fluidized bed

A multi-objective optimization, circulating fluidized bed technology, which is applied in the optimization field of iron and steel sintering circulating fluidized bed production process, can solve the problems of lack of theoretical guidance, high desulfurization cost, and insufficient utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

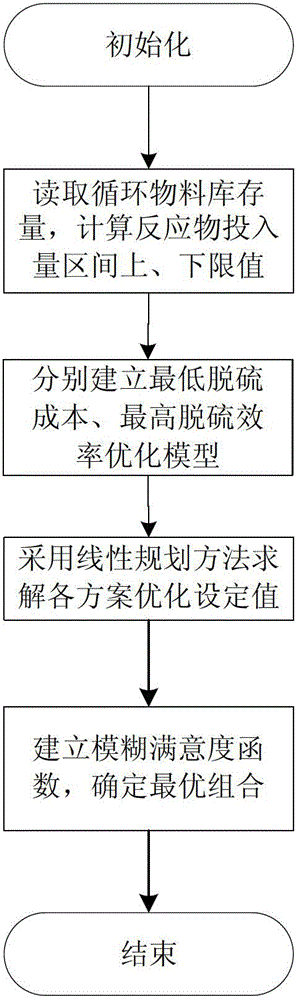

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: Taking the desulfurization process of a circulating fluidized bed in a steel plant as an example to illustrate the superiority of the present invention, the relevant parameters are shown in attached table 1.

[0086] In the first step, according to the pressure difference in the tower and the amount of circulating materials collected in the ash bin, the upper and lower limits of the overall input amount are determined as follows:

[0087] Pressure difference inside the tower: -3900~-4850N;

[0088] Concentration of desulfurizer (Ca): 0.5~2;

[0089] Hydrated lime slurry pump frequency: 0~100(%);

[0090] Circulating material feeder frequency: 0~100(%);

[0091] Spray pump frequency: 0~100(%)

[0092] The second step is to determine the desulfurization efficiency index and desulfurization cost index and the constraints of the operating parameters, respectively:

[0093] Desulfurization efficiency: 90%≤η≤100%;

[0094] About desulfurization cost:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com