Temperature control water nozzle comprehensive detection machine

A testing machine and faucet technology, which is used in measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of low testing accuracy and precision of testing equipment, uneven water temperature, and low adjustment efficiency. , to avoid uncontrollable water sources, ensure stability and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

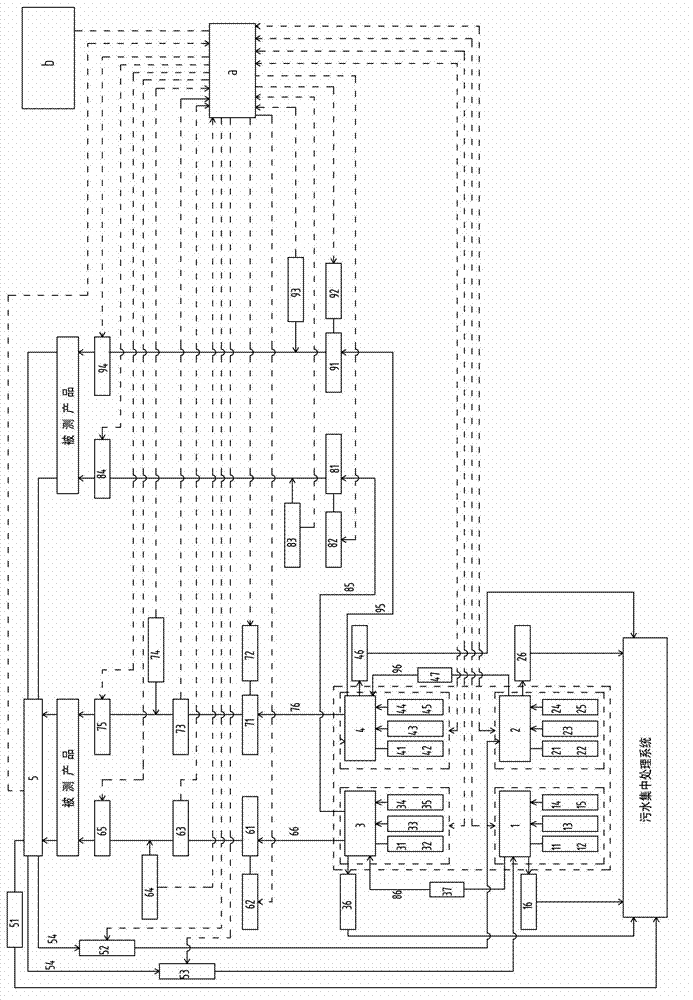

[0022] refer to figure 1 As shown, a temperature-controlled faucet comprehensive detection machine includes a water supply system, a detection device for fixedly installing a faucet, a water recovery system, a programmable logic controller a and a computer or an intelligent human-machine interface b.

[0023] The water supply system includes hot water generation tank 1, hot water supply tank 3, cold water generation tank 2, cold water supply tank 4, flow detection hot water supply pipeline 66, flow detection cold water supply pipeline 76, life detection hot water supply pipeline 85, life detection Cold water supply pipeline 95, transfer pump 61, 71, 81, 91 arranged on each water supply pipeline, pressure sensor 64, 74, 83, 93 arranged on each water supply pipeline connected with programmable logic controller a, setting The water supply switch valves 65, 75, 84, 94 connected to the programmable logic controller a on each water supply pipeline, the flow sensors 63, 73 arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com